Pneumatic isobaric multi-stage sealing device for wellhead of oil pumping unit

A technology for pumping wells and sealing devices, used in sealing/packing, drilling equipment, wellbore/well components, etc., can solve the problems of oil leakage pollution, high frequency of replacement of packing, and large power consumption, etc. Extended service life, long sealing cycle, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

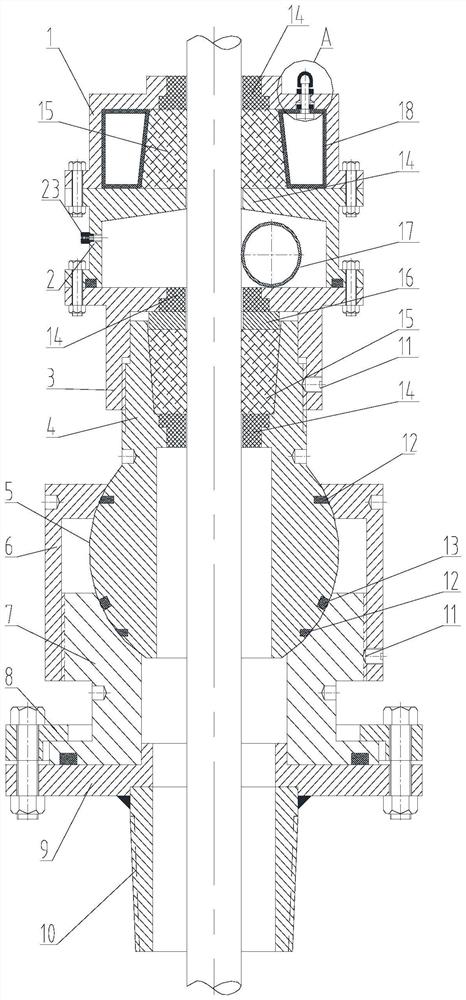

[0023] The present invention will be further described below in conjunction with the accompanying drawings:

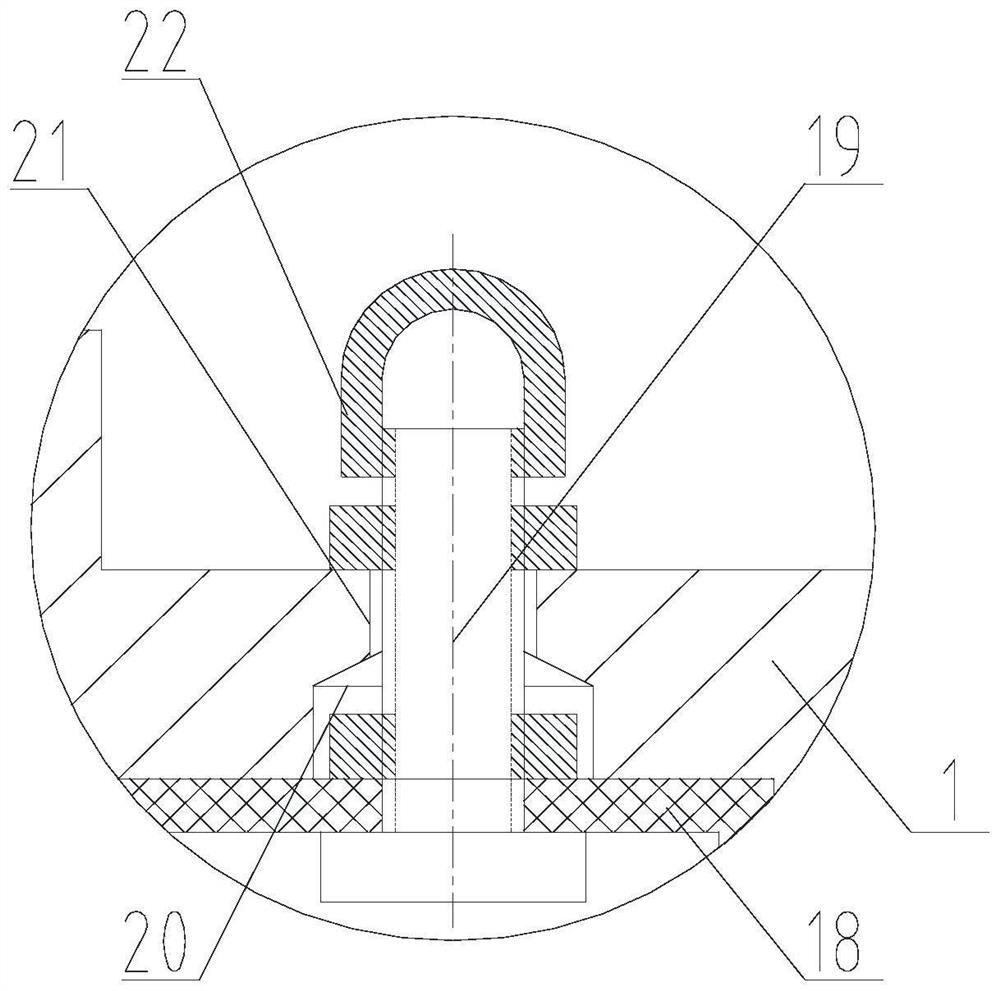

[0024] Depend on figure 1 combine Figure 2~3 As shown in the figure, the pneumatic isobaric multi-stage sealing device for the wellhead of the pumping unit includes an upper section 1, the lower end of the upper section 1 is connected to the middle section 2 by flanges and bolts, and a packing 15 is clamped between the upper section 1 and the middle section 2, An air bag 18 is installed in the space between the upper section 1 and the middle section 2 outside the packing 15;

[0025] The more traditional packing box airbag 18 has energy storage function. Inflatable sealing packing is used in the design, which is filled with high-pressure gas, and the packing 15 is pressurized with a continuous and uniform force, and can shrink under the action of pressure to ensure the packing. The close coupling between 15 and the sucker rod avoids the increase in the load of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com