Patents

Literature

46results about How to "Prevent blowout accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Supercritical carbon dioxide jet injection drilling exploitation hydrate device and method

InactiveCN104563974AEmission reductionMaintain integrityConstructionsLiquid/gas jet drillingJet injectionHigh pressure

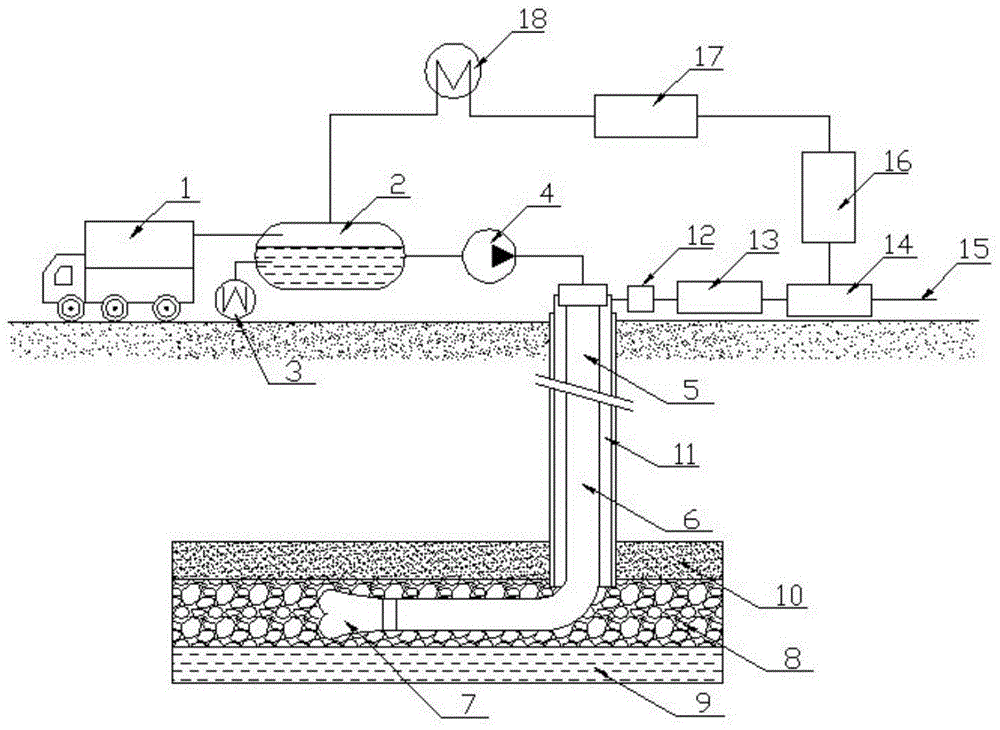

The invention belongs to the technical field of hydrate drilling exploitation equipment and processes and relates to a supercritical carbon dioxide jet injection drilling exploitation hydrate device and method. The supercritical carbon dioxide jet injection drilling exploitation hydrate device is adopted to realize exploitation of hydrate, a carbon dioxide storage device is filled with carbon dioxide firstly, then the carbon dioxide is continuously cooled to the liquid state via a storage tank cooling device, the liquid carbon dioxide is pressurized by a high pressure pump prior to be pumped into a drilling tool for jet drilling by the aid of the prior art, after the drilling tool drills into a hydrate reservoir, the jet temperature of the high-pressure supercritical carbon dioxide injected by a drill bit is lowered, the hydrate brought out of a wellbore and a near wellbore formation moves upwards along an annular space; after reaching a wellhead throttling device, the hydrate sequentially passes through a three-phase separator and a gas separator to spate natural gas and carbon dioxide so as to complete exploitation of the hydrate. The used device is simple in structure, convenient to operate, low in maintenance cost, simple in exploitation method, scientific in principle and safe in exploitation process.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

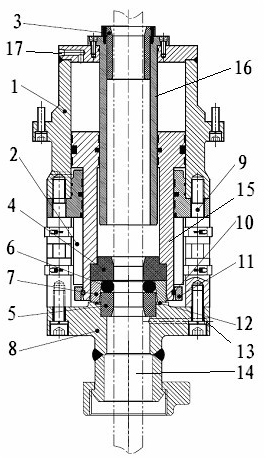

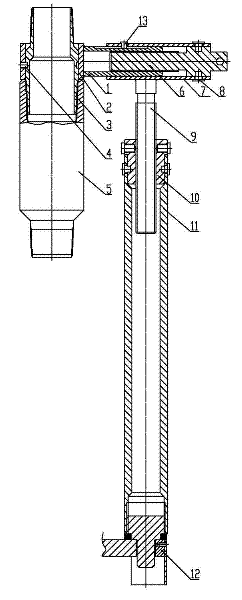

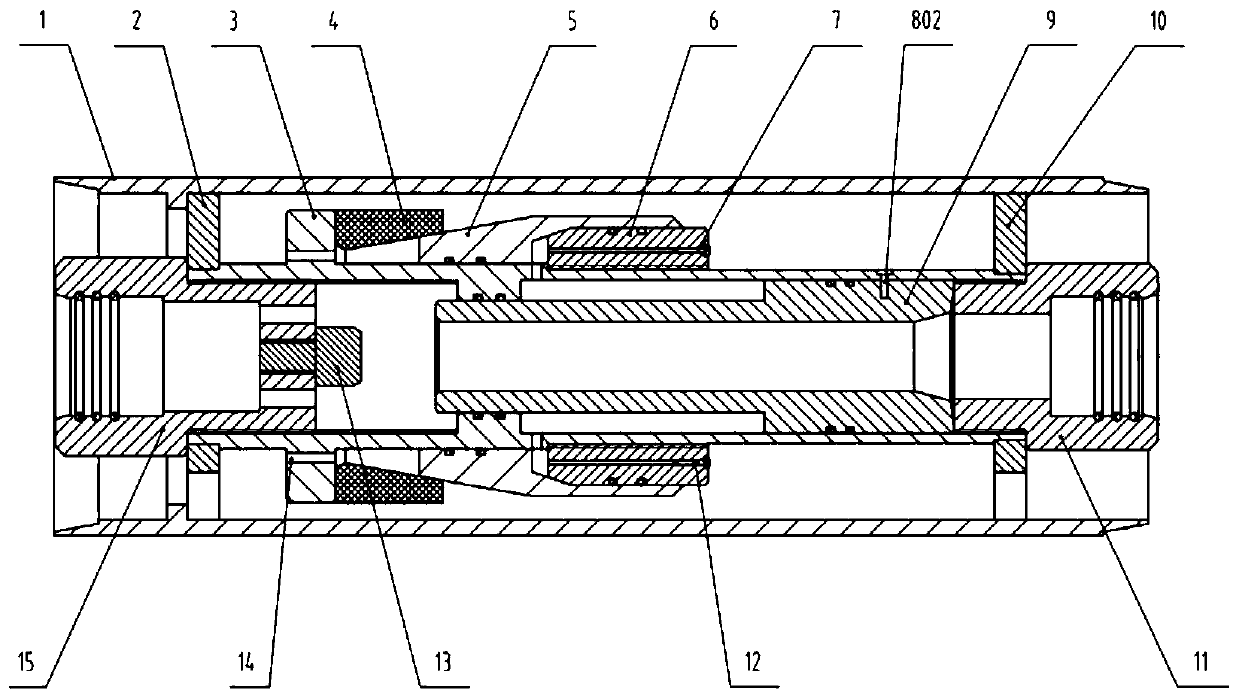

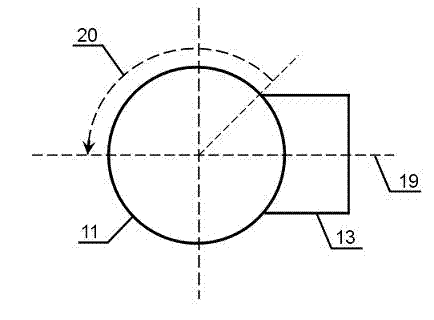

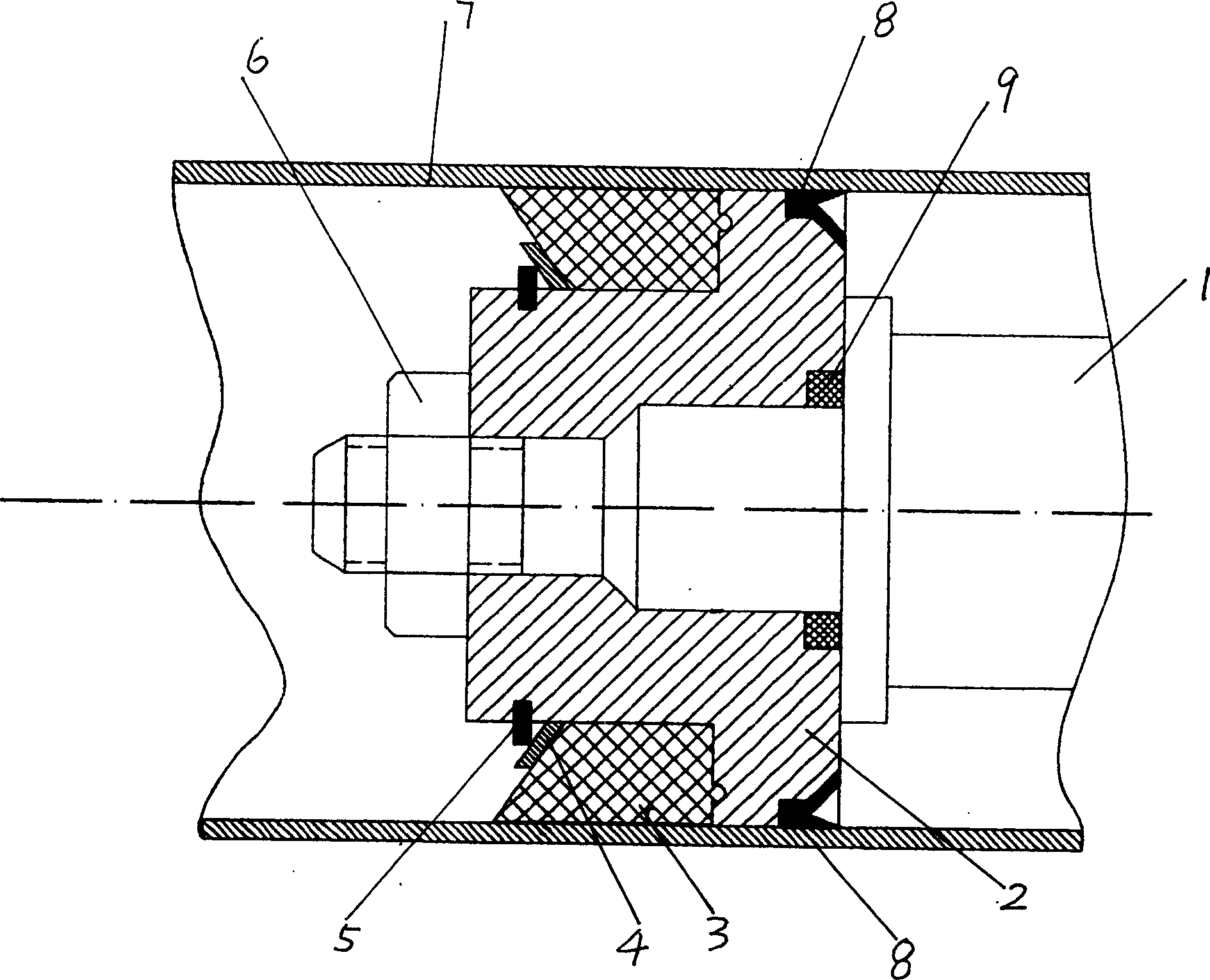

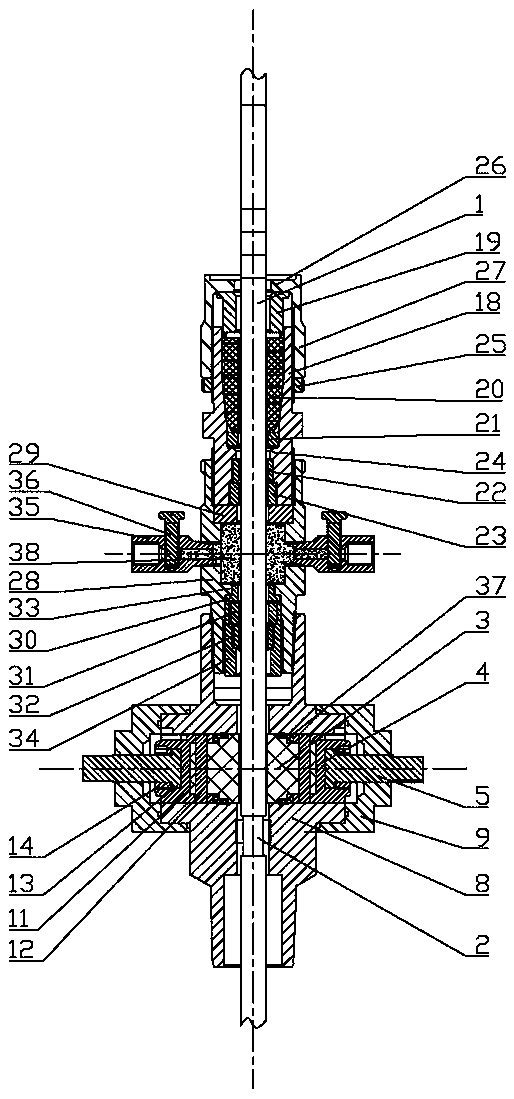

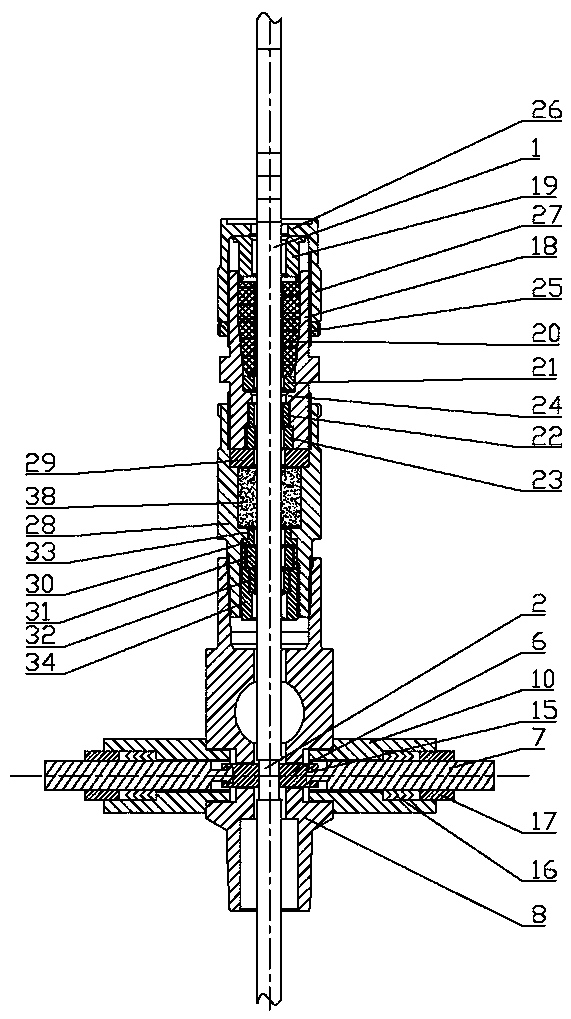

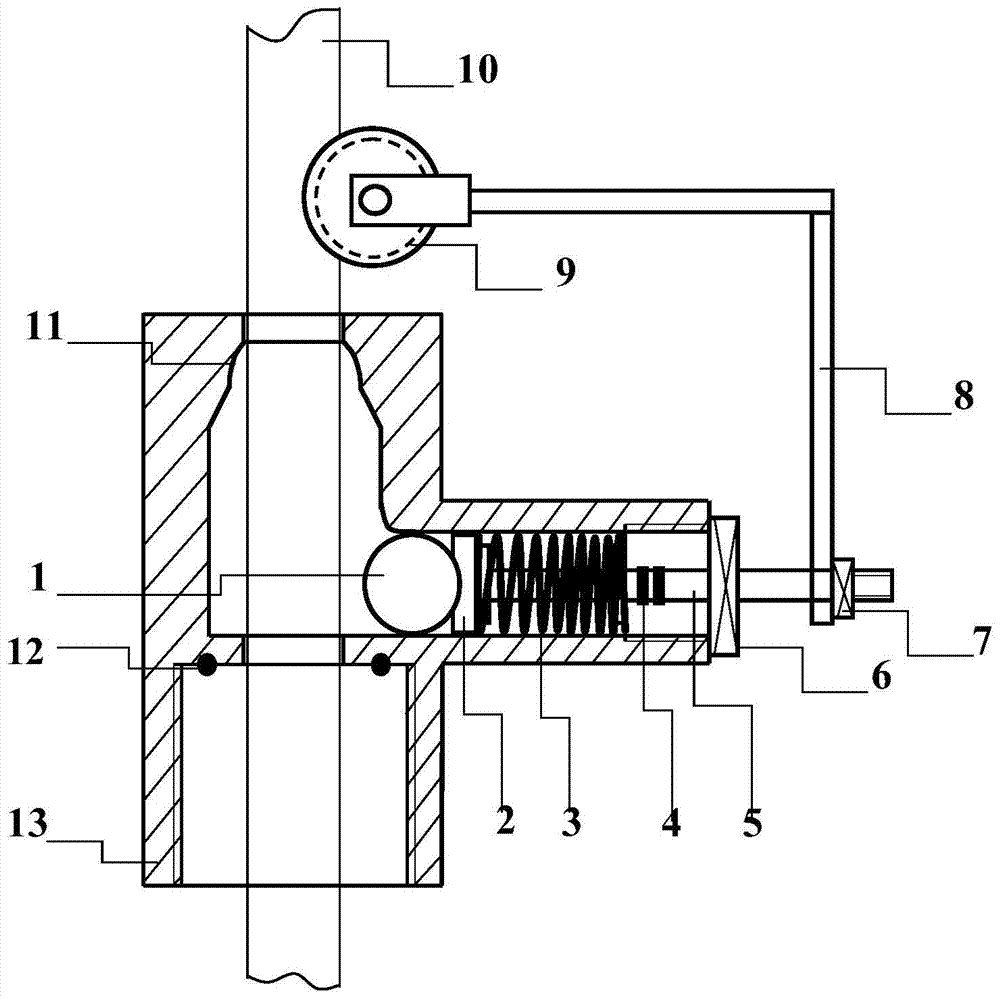

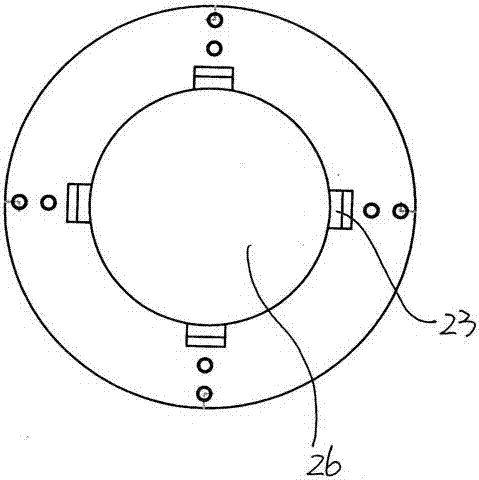

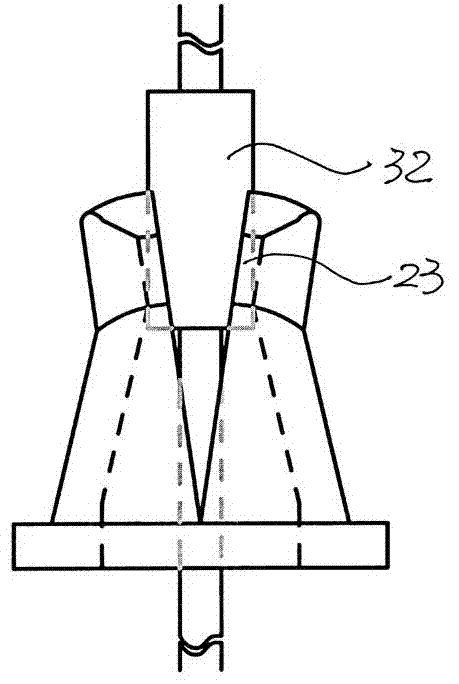

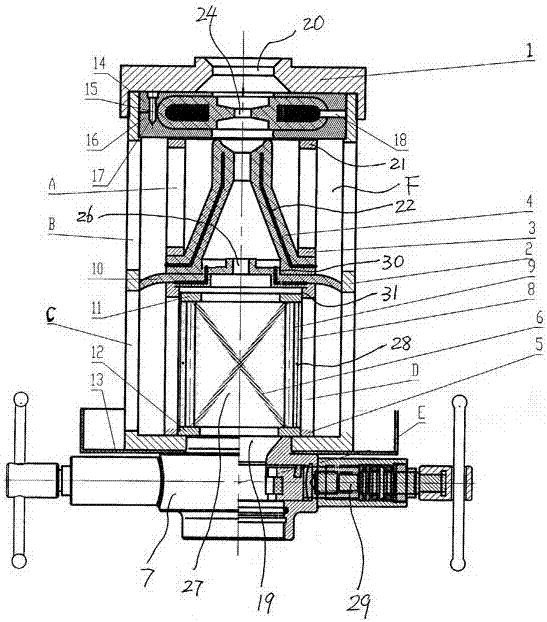

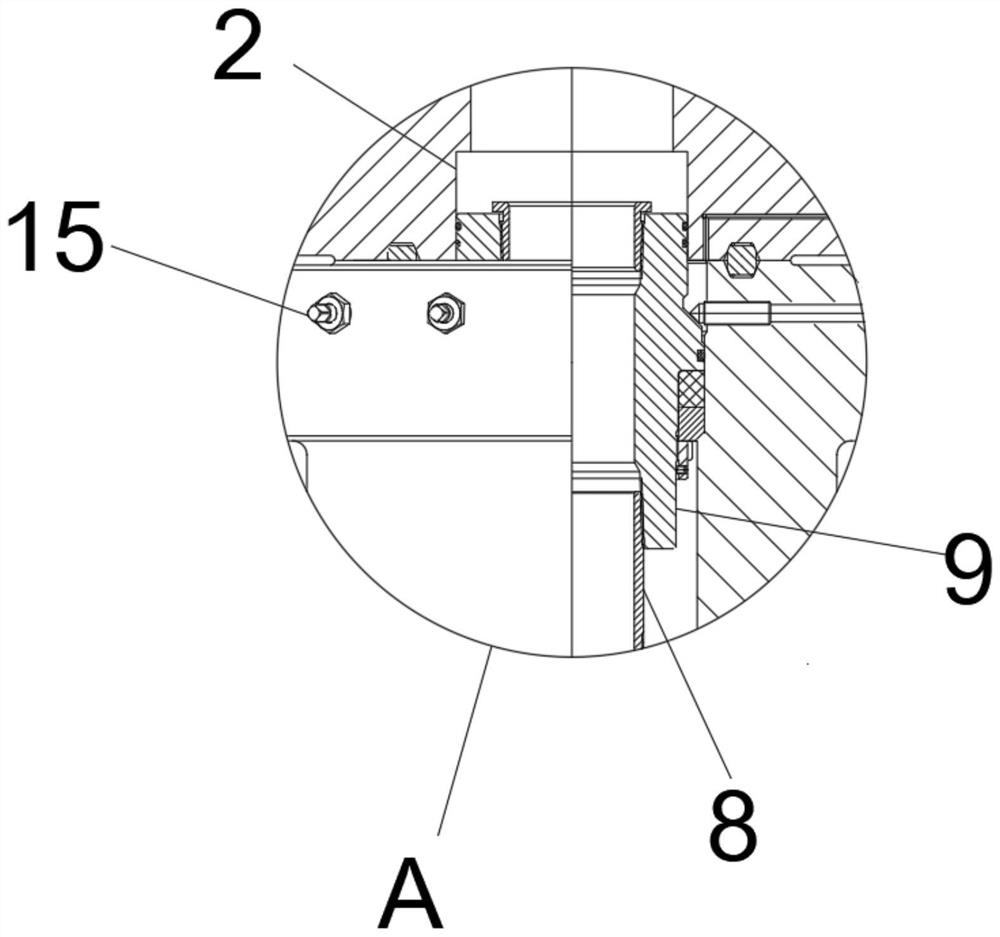

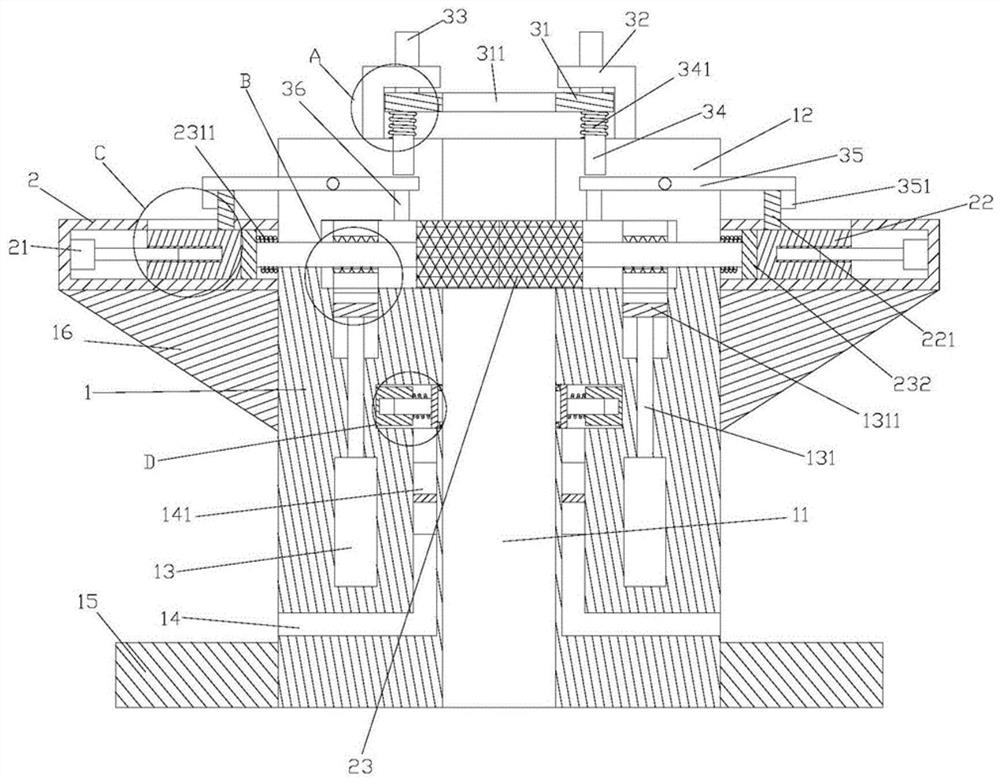

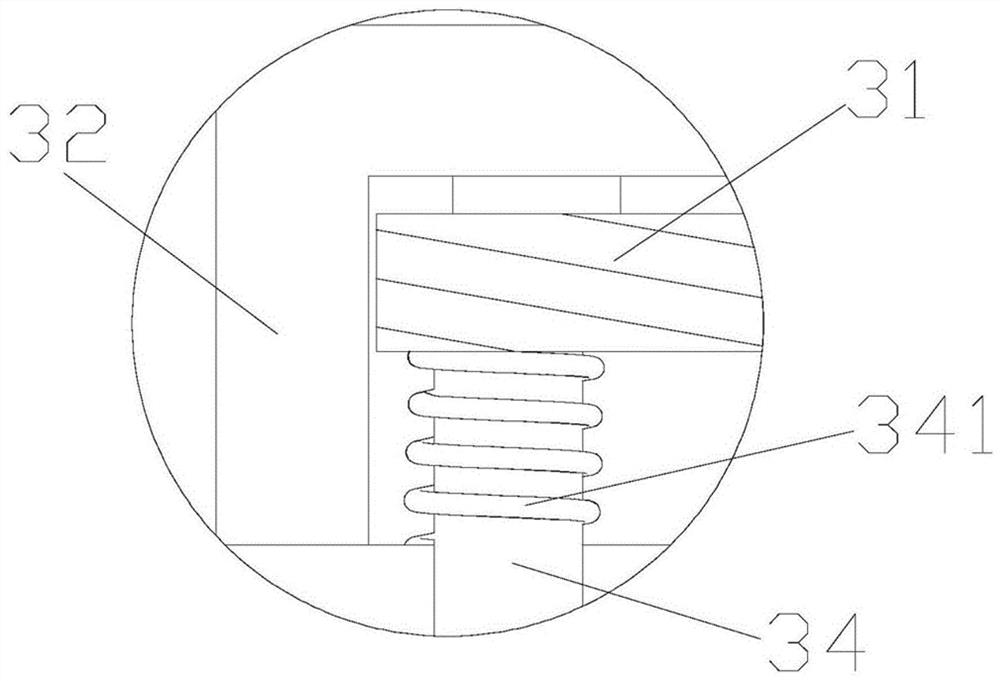

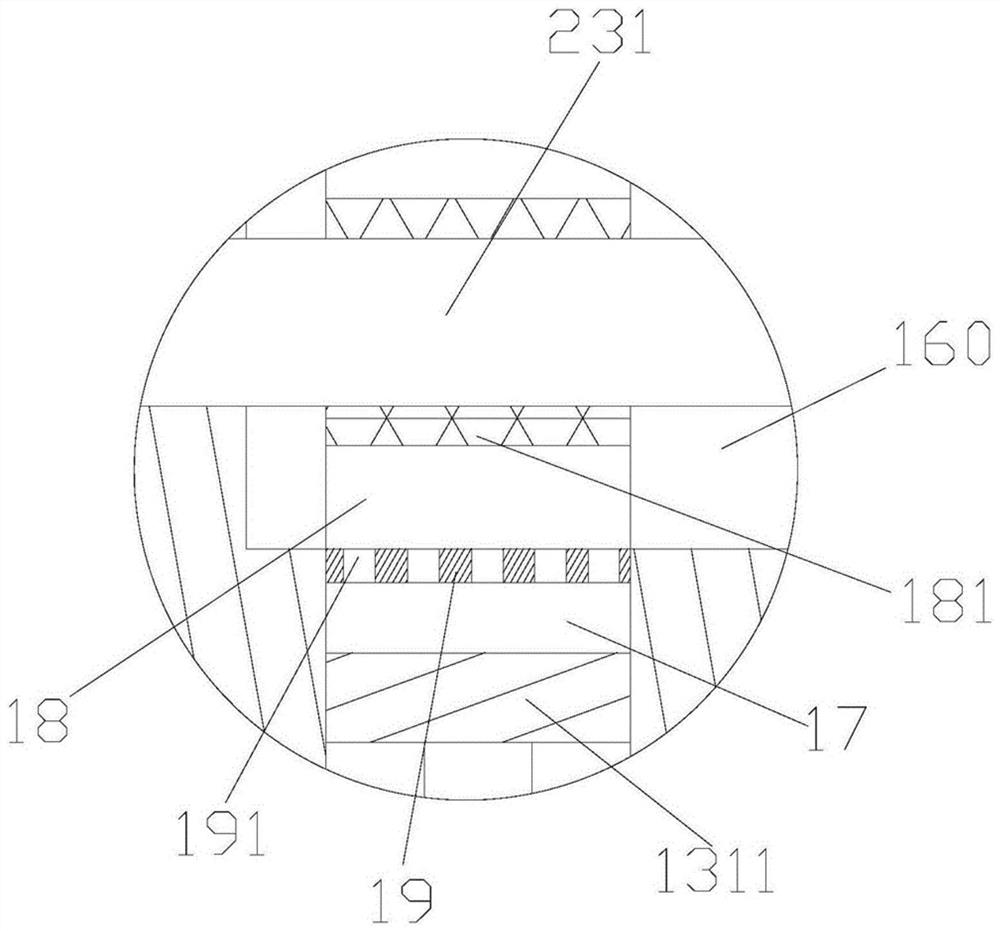

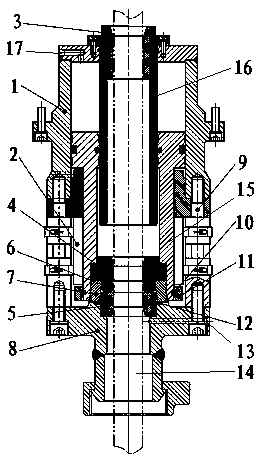

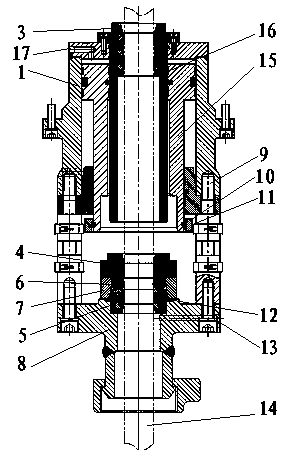

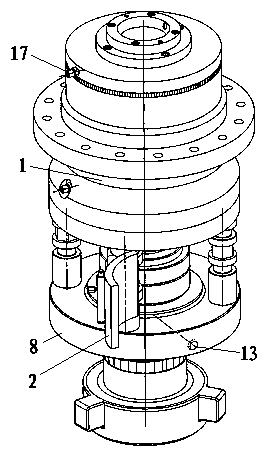

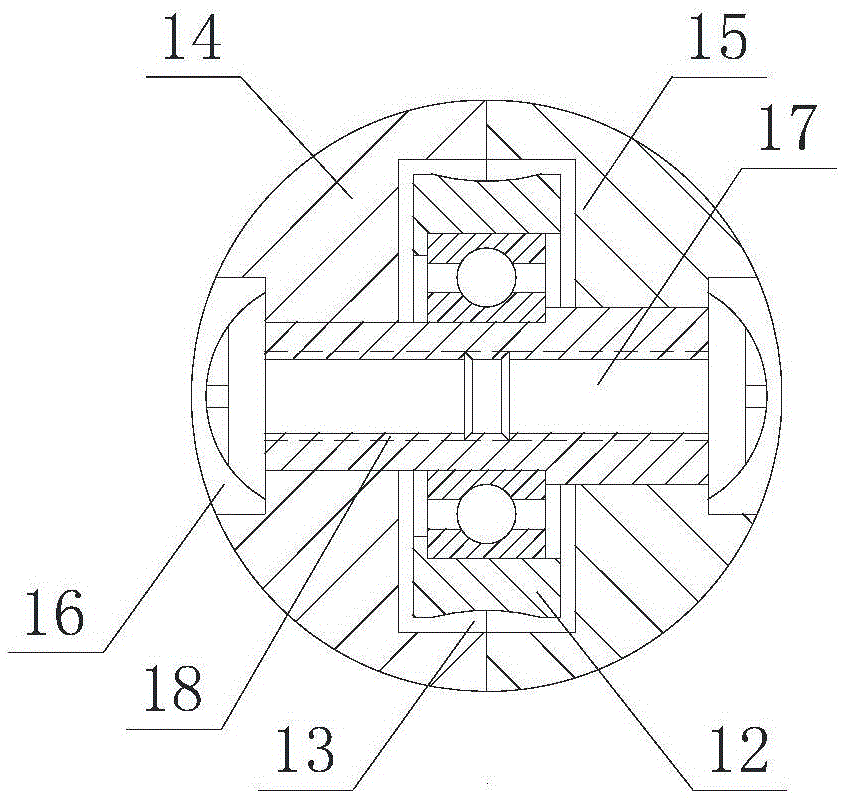

Blowout preventing box of continuous oil pipe and drill rod

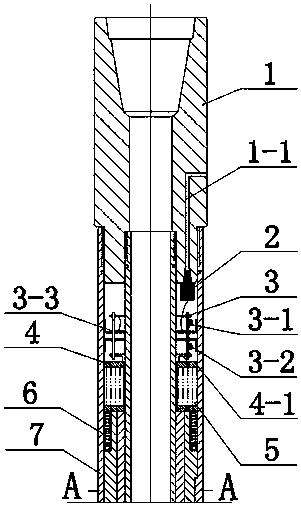

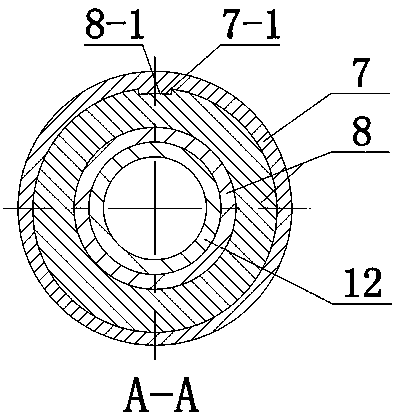

The invention discloses a blowout preventing box of a continuous oil pipe and a drill rod. The blowout preventing box comprises a hollow hydraulic cylinder and a flange union connected through connecting rod bolts, and a set of valve assembly is arranged on the two connecting rod bolts opposite in the diameter direction respectively; the hollow hydraulic cylinder is arranged at a hydraulic inlet / outlet; a fixed sleeve is arranged in the cavity of the hollow hydraulic cylinder, an upper guide sleeve is sleeved at the upper end of the inner wall of the fixed sleeve, the upper guide sleeve and the interior of the flange union axially pass through the continuous pipe, a piston rod is arranged between the fixed sleeve and the hollow hydraulic cylinder, and the inner circumference of the lower section of the piston rod is provided with a seam allowance; and a middle guide sealing pressing sleeve and an inner cone guide spacing ring are sleeved on the inner circumference of the seam allowance, the inner circumference of the middle guide sealing pressing sleeve is sleeved with the continuous pipe, a main sealing ring and a lower guide sealing pressing sleeve are arranged between the inner cone guide spacing ring and the continuous pipe, and a hydraulic detection port is bypassed in the radial direction of the flange union. The pressure adjustment of the sealing cavity is convenient; time and labor are saved when the sealing ring is replaced; and the pressure of a wellhead can be detected in real time.

Owner:BAOJI PETROLEUM MASCH CO LTD

Oil well blowout control device

The invention discloses an oil well blowout control device. The lower part of an adjusting pipe is mounted on a fixing plate; the upper part of the adjusting pipe is provided with a vertical nut; the vertical nut and a vertical screw are in rotary fit; a sleeve is fixed on the upper part of the vertical screw; the axis of the sleeve is vertical to the axis of the vertical screw; the sleeve is sleeved outside a transverse nut; an anti-rotation dowel is mounted between the sleeve and the transverse nut; the transverse nut and a transverse screw are in rotary fit; the transverse screw is connected to the sleeve through an anti-movement dowel; a clamp sleeve is fixed at the left end of the transverse nut; the axis of the clamp sleeve is vertical to the axis of the transverse nut; a variable buckle joint is placed in the clamp sleeve and limited in the clamp sleeve by a limiting dowel; the lower part of the variable buckle joint is connected with a blowout preventer; and the blowout preventer can rotate around the axis of the adjusting pipe, or go up and down or extend inwards and outwards, and can be conveniently and quickly mounted on an oil pipe to blow out on an oil well so as to prevent blowout accidents. Thus, the oil well blowout control device avoids severe economic loss and personal injury caused by blowout, thereby having obvious economic and social benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

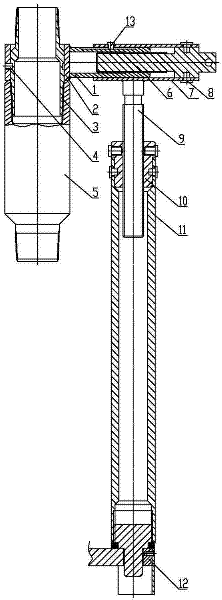

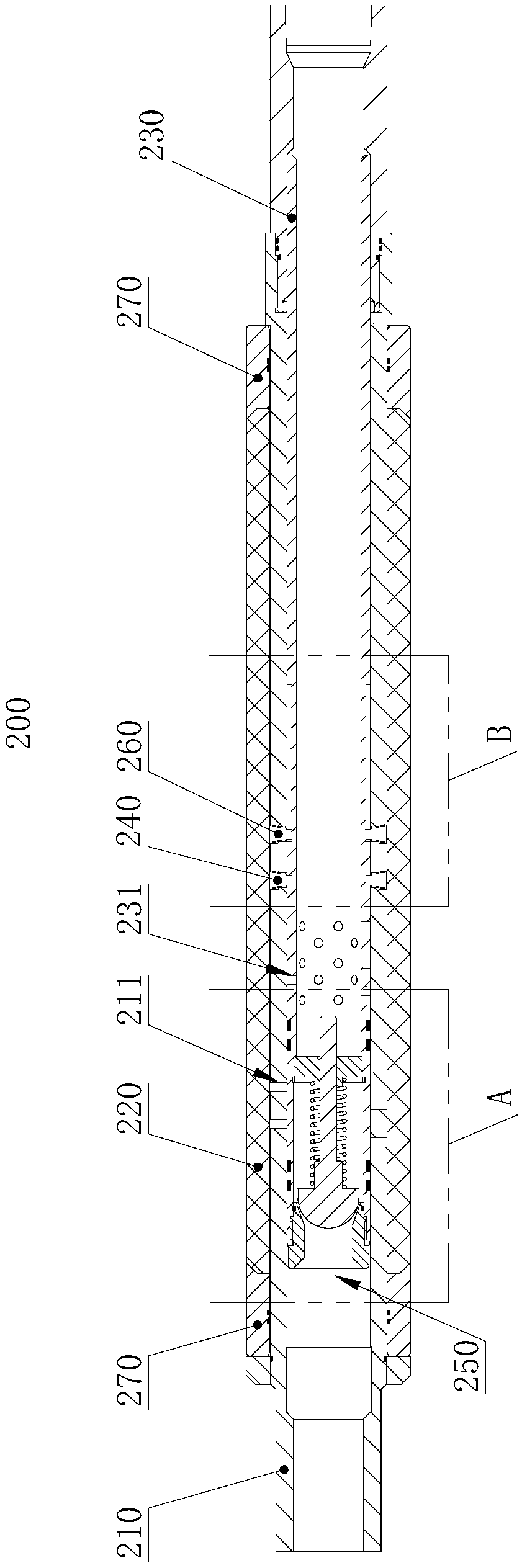

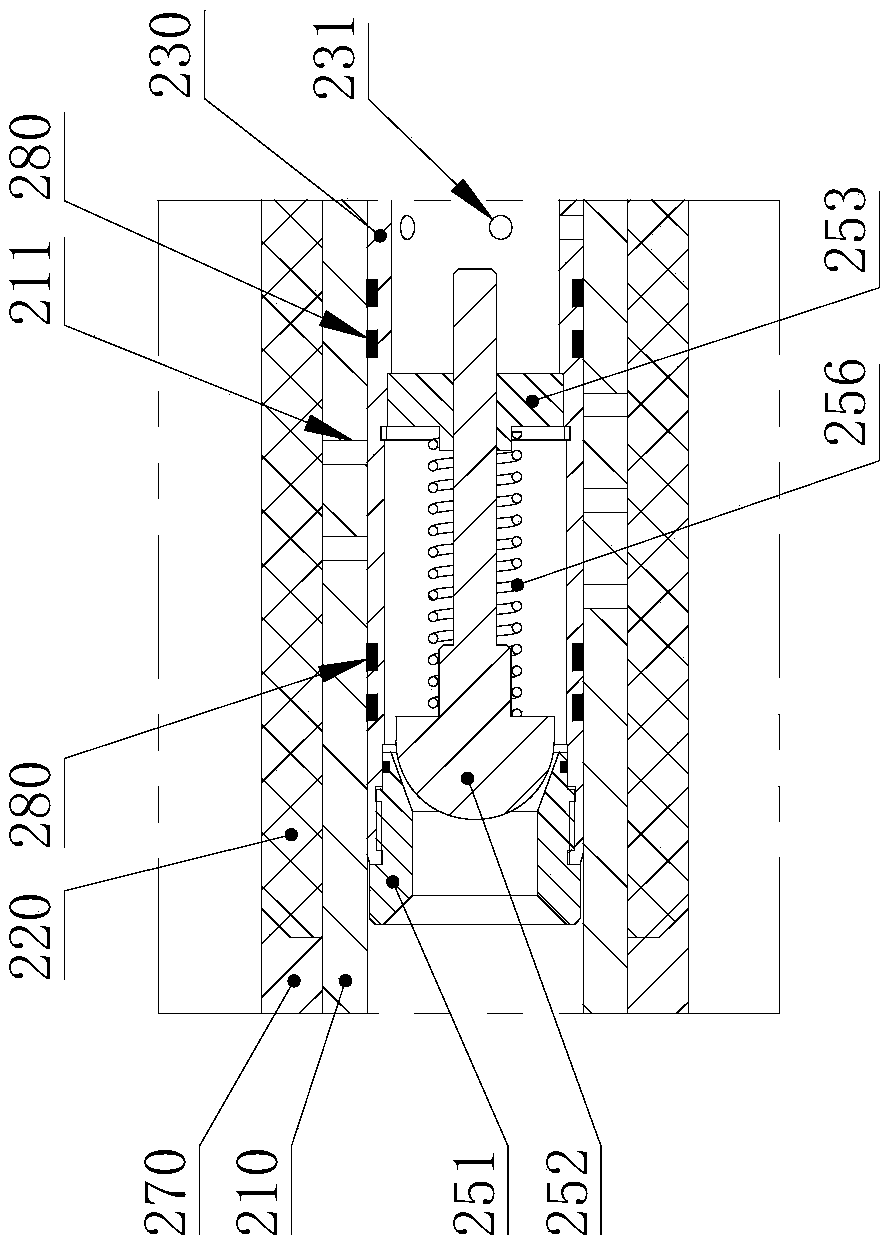

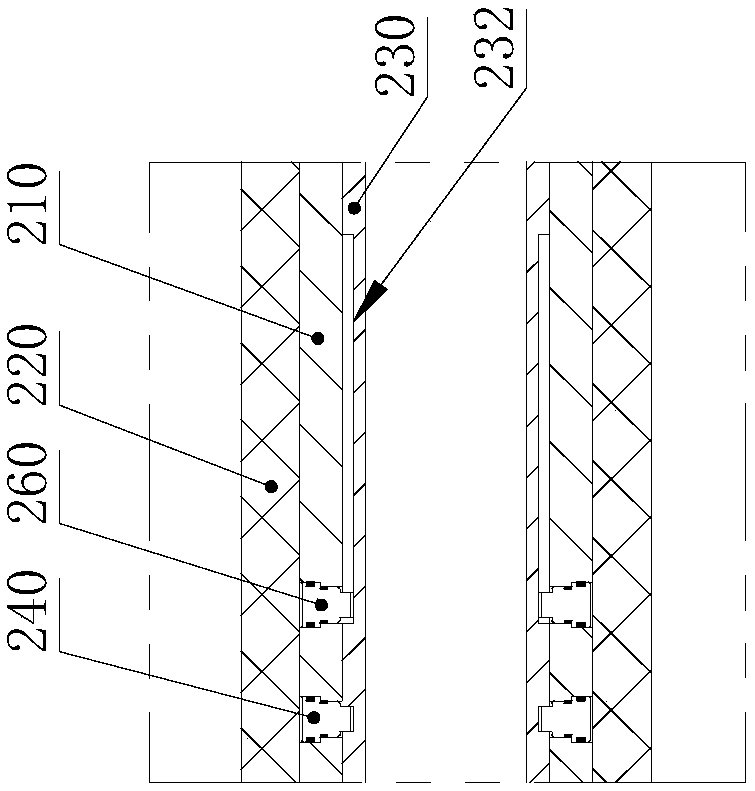

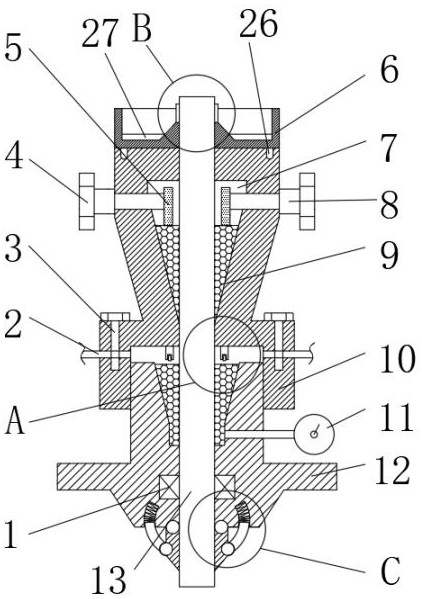

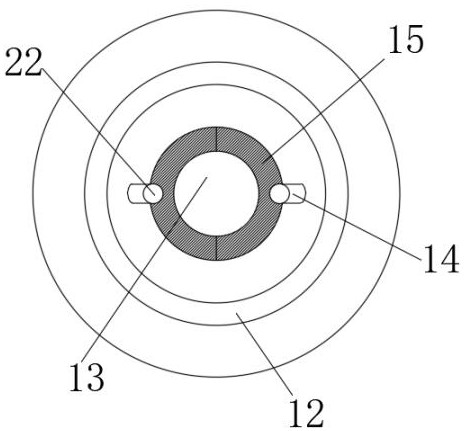

Blow-out prevention valve in double-layer pipe

ActiveCN111456681APrevent well kickPrevent blowout accidentsWell/borehole valve arrangementsSealing/packingUpper jointDouble-walled pipe

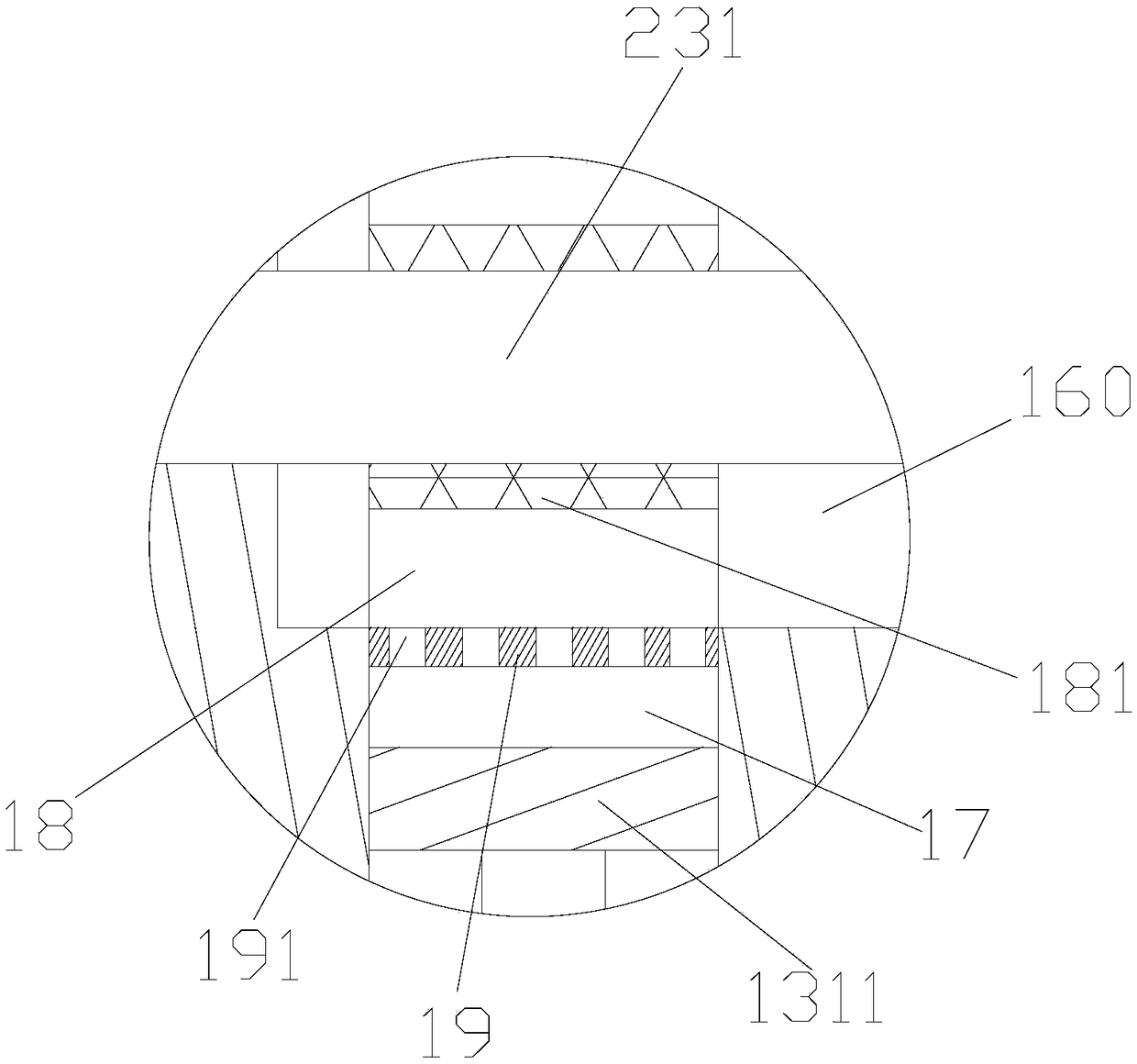

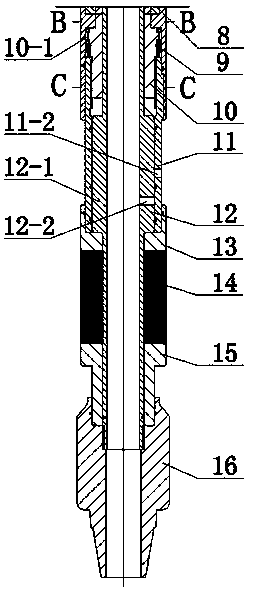

The invention provides a blow-out prevention valve in a double-layer pipe. The device comprises a piston, a rubber core, a valve seat, a differential pressure sliding sleeve, a supporting plate, an inner pipe, an outer pipe, an upper joint of the inner pipe and a lower joint of the inner pipe. The differential pressure sliding sleeve is located in an inner pipe cavity and is positioned by an innerpipe step and the lower joint of the inner pipe; the piston and the rubber core are located on the outer wall of the inner pipe and are positioned by the inner pipe step and the valve seat, and a cavity formed by the piston, the valve seat and the outer wall of the inner pipe communicates with a cavity formed by the differential pressure sliding sleeve and the inner pipe; and the supporting plateis fixed to the inner pipe step through the upper joint of the inner pipe and the lower joint of the inner pipe, and the inner pipe is positioned by an outer pipe step. According to the blow-out prevention valve in the double-layer pipe, self-closing can be realized in case of overflow during double-layer pipe drilling or mining, the occurrence of well kick or blowout accidents is effectively prevented, and power fluid can be used for reopening after the environment in the well is stable to continue drilling or mining, time is saved, the drilling and milling efficiency is improved.

Owner:SOUTHWEST PETROLEUM UNIV

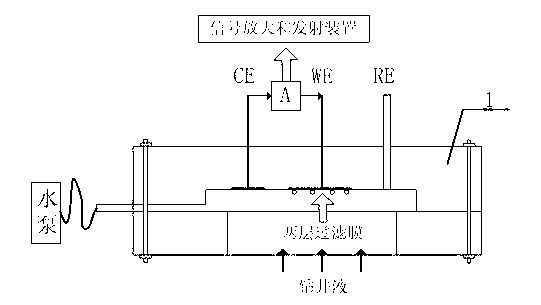

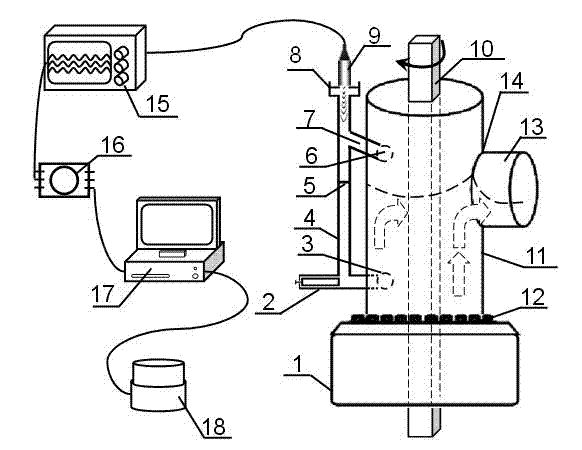

Slurry gas detecting method in pit

The invention discloses a slurry gas detecting method in a pit, and aims to solve the problem of poor real-time performance of existing detecting techniques in the field of slurry gas detection. The detecting method includes that on the basis of an electrochemical detection principle, slurry passes an electrochemical detecting chamber and two layers of filtering films, redox reactions are generated on three electrodes by gas to generate currents, and after signal processing, the currents are transmitted by a transmitting device to a well drilling platform for judgment by on-duty operators. The electrochemical detecting chamber and two layers of filtering film structures formed by a punched-plate composite sintered metal filter and gas-transmitting films are designed, and the slurry gas detecting method is applicable to three-electrode electrochemical testing systems for methane detection as well as signal processing and transmitting devices of gas detecting signals. The slurry gas detecting method is applicable to real-time detection, and real-time slurry gas detection in the pit can be realized, so that blowout accidents can be prevented in advance, geologists are assisted to find and evaluate underground oil gas, and important research value is provided.

Owner:SOUTHWEST PETROLEUM UNIV

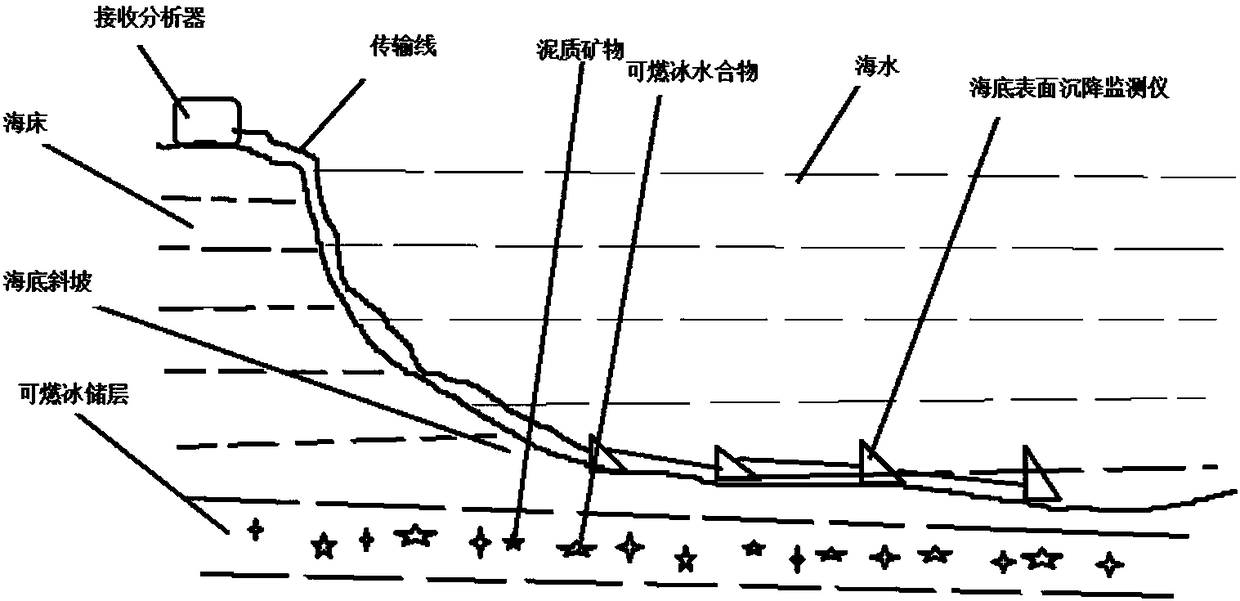

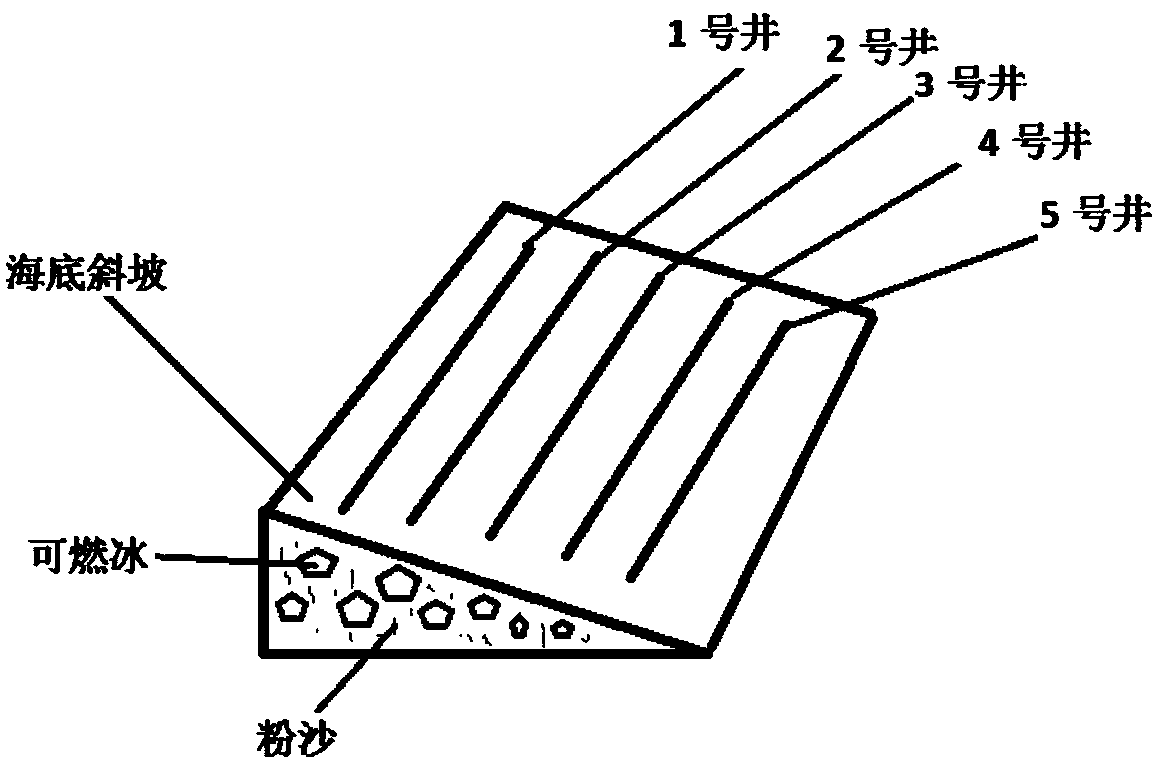

Safe combustible ice mining method in seabed shallow layer

ActiveCN108625827AAchieve buckSafe and stable operationConstructionsFluid removalOcean bottomWater vapor

The invention provides a safe combustible ice mining system and method in a seabed shallow layer. The safe combustible ice mining method comprises the following steps that a pre-development section isdetermined; the development program of combustible ice is developed; a row of 5-6 horizontal well sets are distributed; drilling is performed in the positions of the horizontal well sets; slotting treatment is performed around a shaft after drilling; pulling out of hole of a drill is performed; the completion fluid in the shaft is replaced; vapour with temperature being 120DEG C-180DEG C and pressure being 20MPa-30MPa is injected into separated wells in the 5-6 horizontal well sets; the water mist in the ejected gas is observed; ignition is performed; and the wellhead gas is incorporated intoa gas outlet pipeline. According to the features such as seabed topography and geomorphology, engineering geological characteristics, and a combustible ice reservoir in the hydrate area, the environmental problems and disasters caused by methane leakage are avoided from engineering through reasonable well location layout and pressure lowering schemes.

Owner:杨浩祥

Device and method for measuring return flow of L-shaped communicating pipe drilling liquid

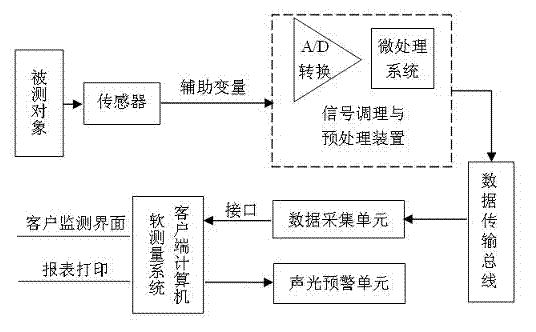

InactiveCN102230812AEarly warning timeImprove detection accuracyVolume/mass flow by mechanical effectsSufficient timeSignal conditioning

The invention relates to a device for measuring a return flow of L-shaped communicating pipe drilling liquid and a method for measuring a return flow of L-shaped communicating pipe drilling liquid. The device for measuring a return flow of L-shaped communicating pipe drilling liquid consists of an optical liquid level sensor, an L-shaped communicating pipe, a flare pipe, a communication pipe bracket, a signal conditioning and pre-processing device, a data acquiring unit, a client computer and a sound and light alarm device, wherein the pipeline of the flare pipe is provided with an L-shaped communicating pipe; the L-shaped communicating pipe and the flare pipe form a communicating vessel; the vertical position of the window of the L-shaped communicating pipe is positioned between a pipeline flange plate of the flare pipe and the lower edge of a return pipeline; the circumferential direction of the window of the L-shaped communicating pipe anticlockwise rotate between the extended lines of the return pipeline central line from the intersecting line of the return pipeline and the pipeline of the flare pipe; and the optical liquid level sensor is arranged on the L-shaped communicating pipe bracket. In the invention, the pre-warning time is early; the detection precision is high; workers at the drilling site have more sufficient time to close the well; and blowout accidents are effectively prevented.

Owner:NORTHEAST GASOLINEEUM UNIV

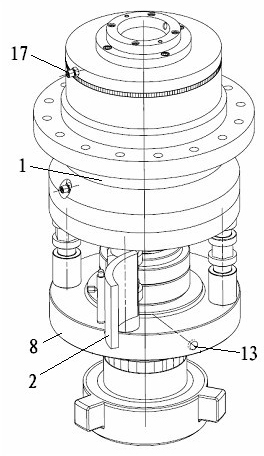

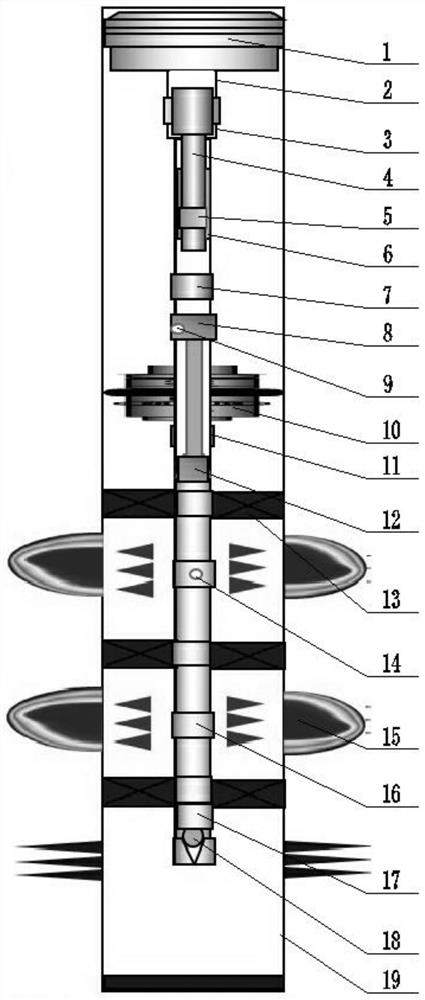

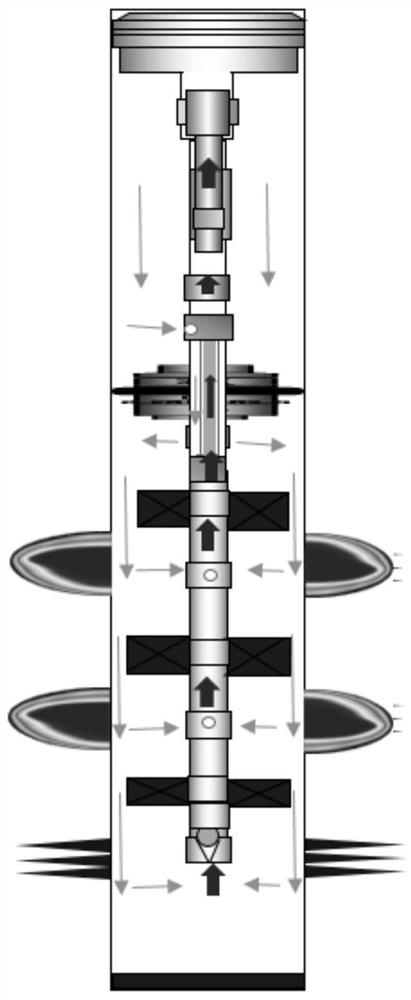

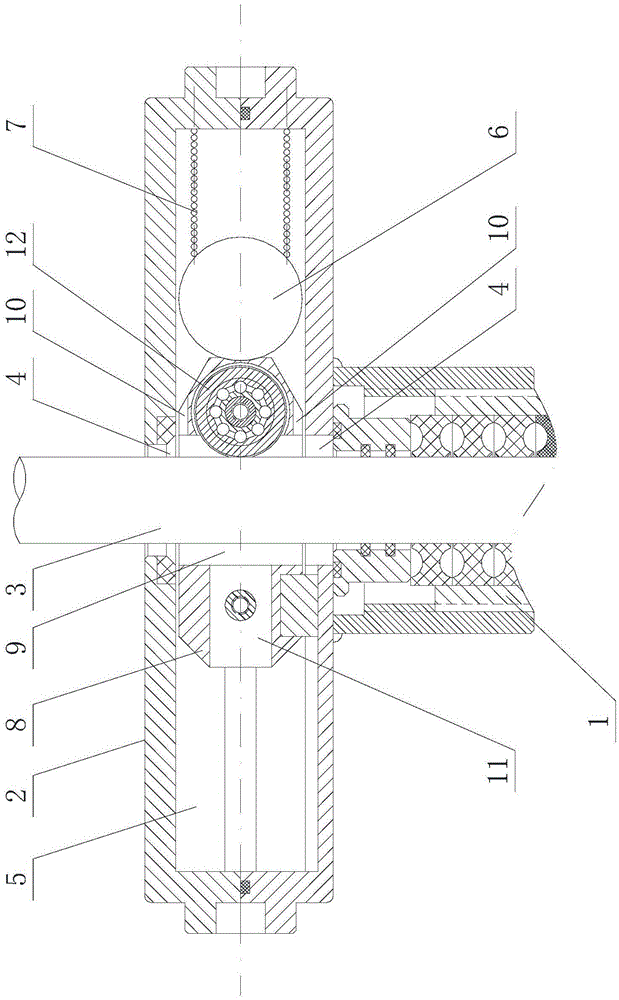

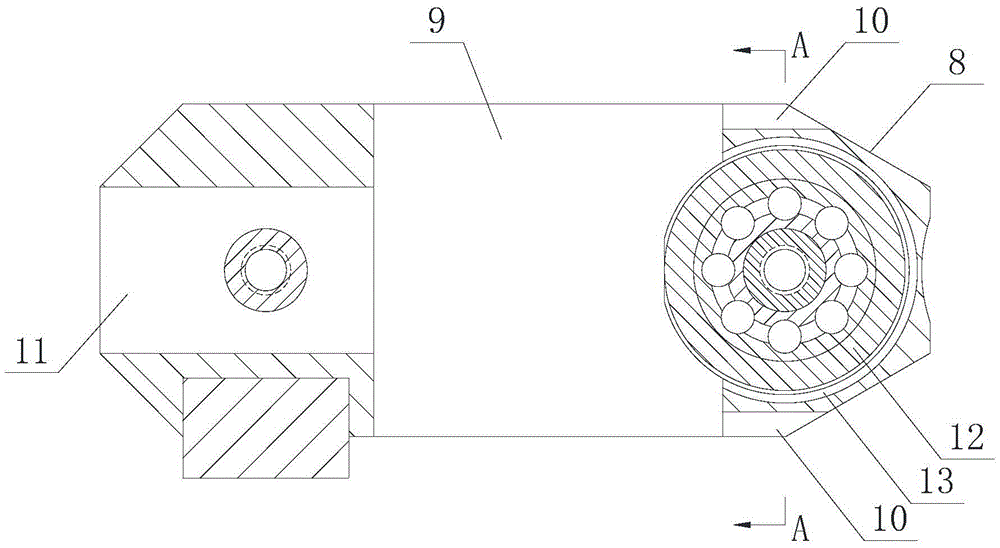

Wellbore blowout prevention packer

PendingCN111411914ABlowout preventionFast implementation of blowout preventionSealing/packingStructural engineeringBlowout preventer

The invention discloses a wellbore blowout prevention packer. The wellbore blowout prevention packer comprises an anchoring assembly and a blocking assembly, and further comprises an anchor sealing operation assembly, the blocking assembly is connected to the lower end of the anchoring assembly, the anchor sealing operation assembly is inserted into the inner cavities of the anchoring assembly andthe blocking assembly, the anchor sealing operation assembly is connected with an anchoring shifting fork of the anchoring assembly through a self torque pipe in a transmission mode, and the anchor sealing operation assembly is connected with a lower joint of the blocking assembly through a self central pulling pipe. According to the wellbore blowout blocking preventer, when the wellbore operation needs to be switched, the blowout preventer does not need to be removed, the device is directly placed into the wellbore through a derrick lifting system, and the wellbore blocking is quickly achieved through the rotating, lifting, compressing and setting of a hydraulic tong; and blowout accidents are prevented.

Owner:CHINA PETROLEUM & CHEM CORP +1

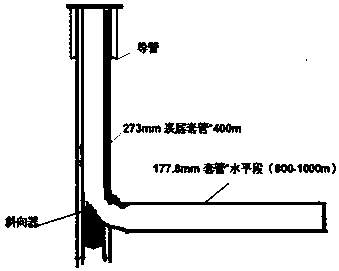

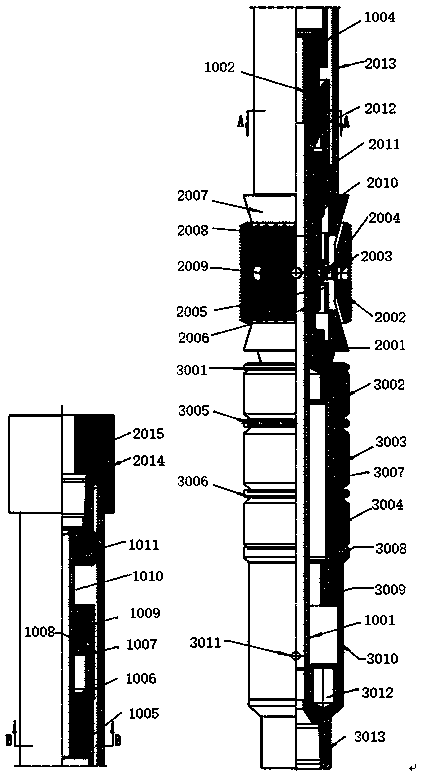

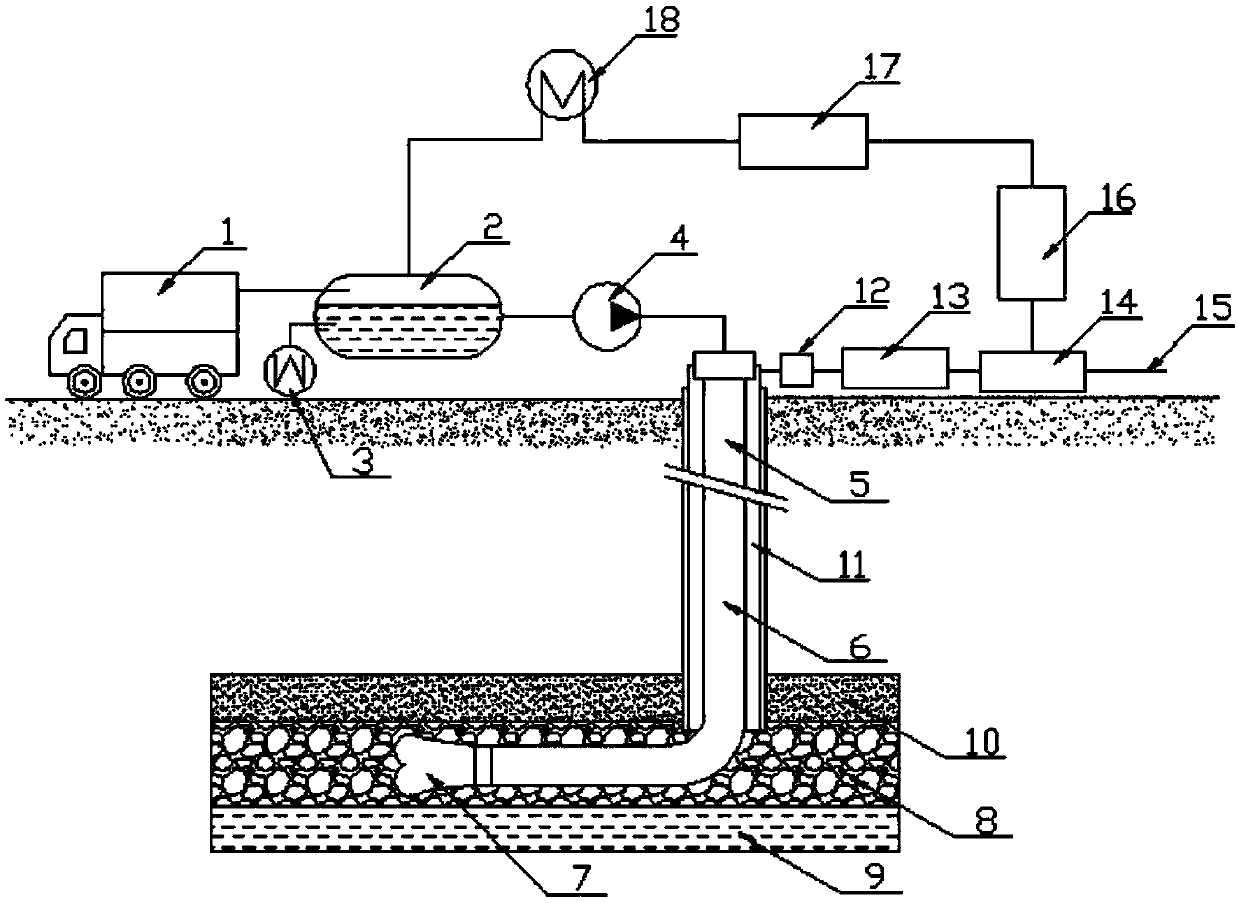

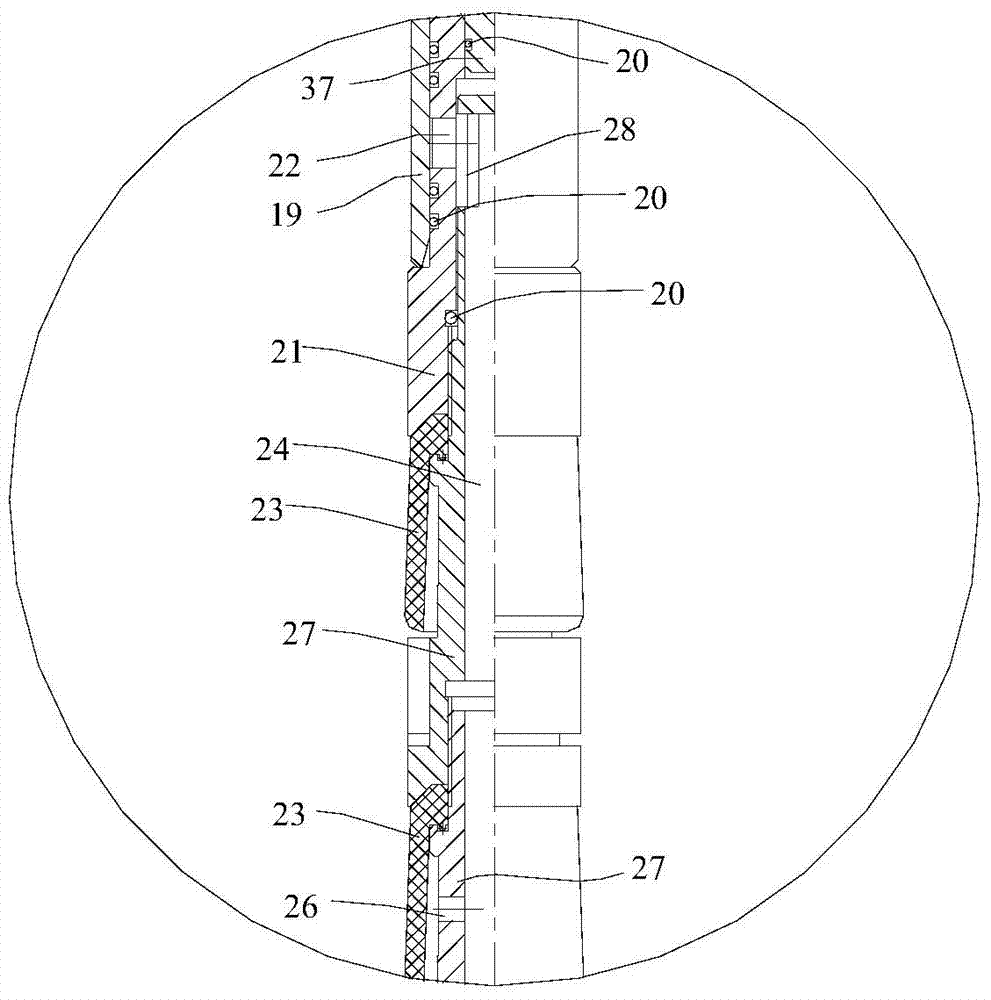

Supercritical carbon dioxide jetting stream well drilling device for exploiting hydrate

InactiveCN107869310APrevent blowout accidentsReduce maintenance costsLiquid/gas jet drillingWell drillingDecomposition

The invention discloses a supercritical carbon dioxide jet drilling device for mining hydrates, belonging to the technical field of hydrate drilling equipment and technology, using supercritical carbon dioxide without water phase as drilling fluid to spray hydrate reservoirs Jet drilling will not cause the re-formation of a large amount of gas hydrate and reduce the production of gas hydrate reservoirs, and the temperature of the carbon dioxide jet will drop sharply due to the existence of the Joule-Thomson effect during the jetting process, which will not be like The rapid decomposition and release of hydrates caused by conventional drilling fluids is beneficial to prevent the occurrence of natural gas hydrate blowout accidents, and the carbon dioxide remaining in the hydrate reservoir after drilling can efficiently replace the natural gas in the hydrate reservoir, forming carbon dioxide Hydrates, whose thermodynamic characteristics are more stable than gas hydrates, can maintain sediment integrity and geomechanical stability.

Owner:滨革能源(青岛)有限公司

Anti-spraying device for while drilling

PendingCN108979582AImprove sealingCooperate wellFlushingWell/borehole valve arrangementsAutomatic controlPetroleum

The invention discloses an anti-spraying device for while drilling, belonging to the technical field of drilling tools for petroleum and gas exploitation. The device comprises a connection drum, the outer side wall of which is equipped with a rubber barrel. A sliding sleeve is arranged on the inner side wall of the connection drum and connected with the connection drum through a first spacing part. The inner side wall of the connection drum is in sealing fit with the sliding sleeve through sealing parts. An inner cavity of the sliding sleeve is equipped with an automatic control valve. At least one first through hole is arranged in the sliding sleeve. The connection drum is equipped with at least one second through hole located between the sealing parts. Each second through hole and each first through hole are staggered from a sealing part. Each second through hole is close to one side where a drilling fluid pipe is located. When well kick happens under the shaft, passages where fluidsflow out of an inner cavity of a drilling column and an outer ring cavity of the drilling column are timely intercepted. Therefore, manual operation by operation staff is not needed. Accordingly, anblowout accident caused by mis-operation or untimely operation is avoided.

Owner:SICHUAN KUNLUN GASOLINEEUM EQUIP MFG

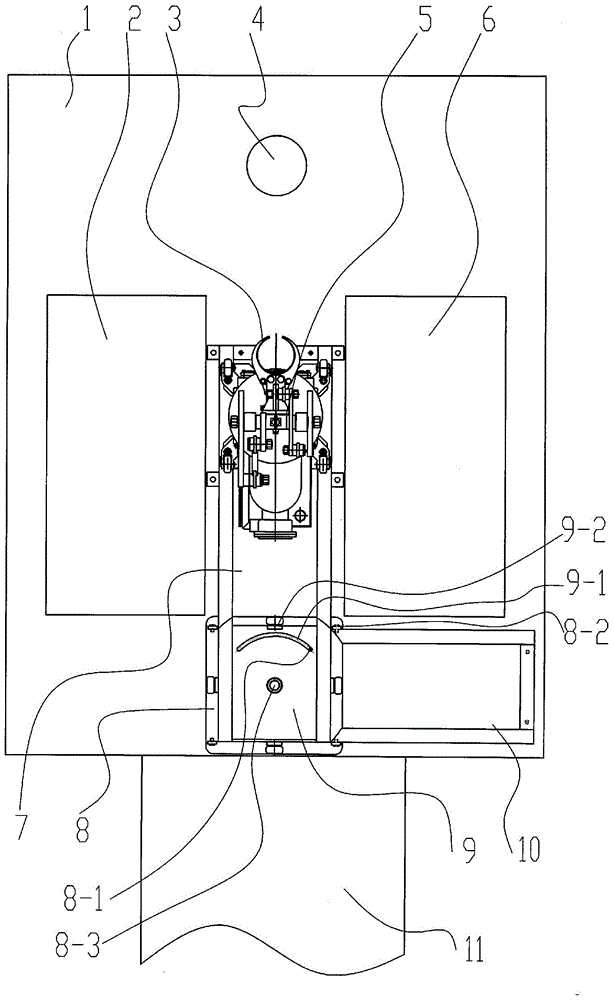

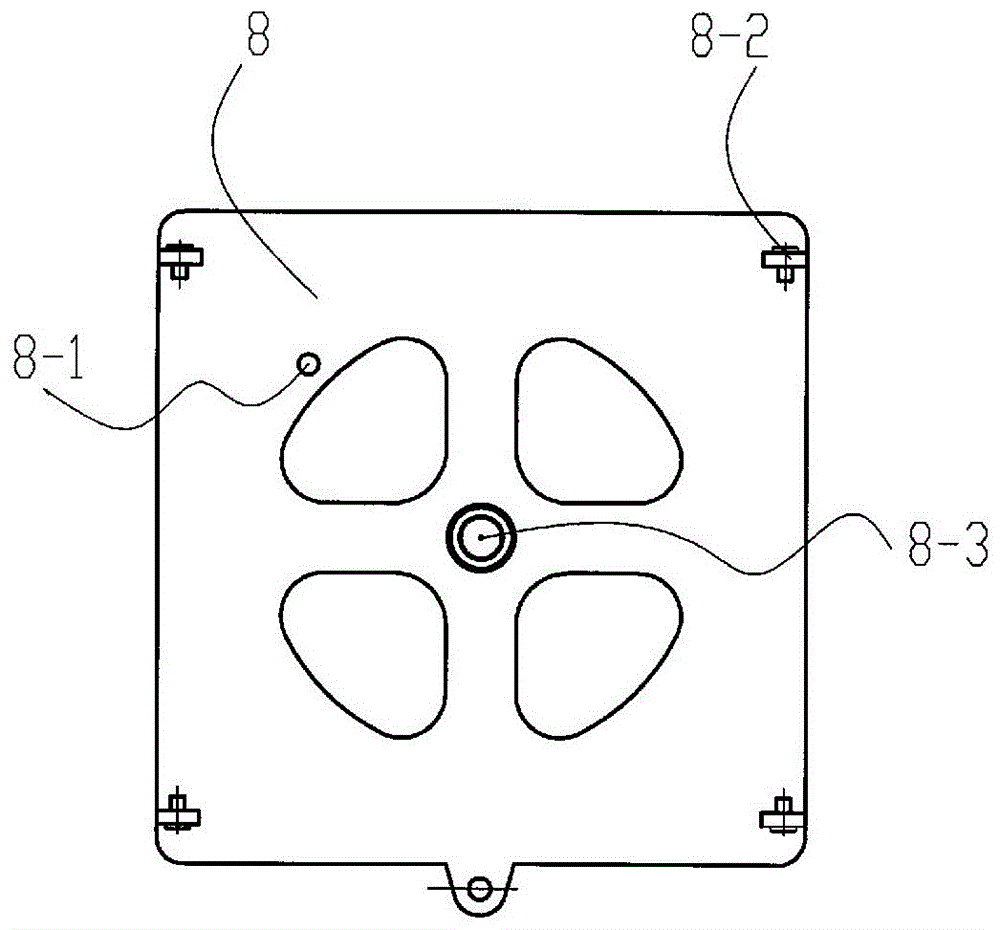

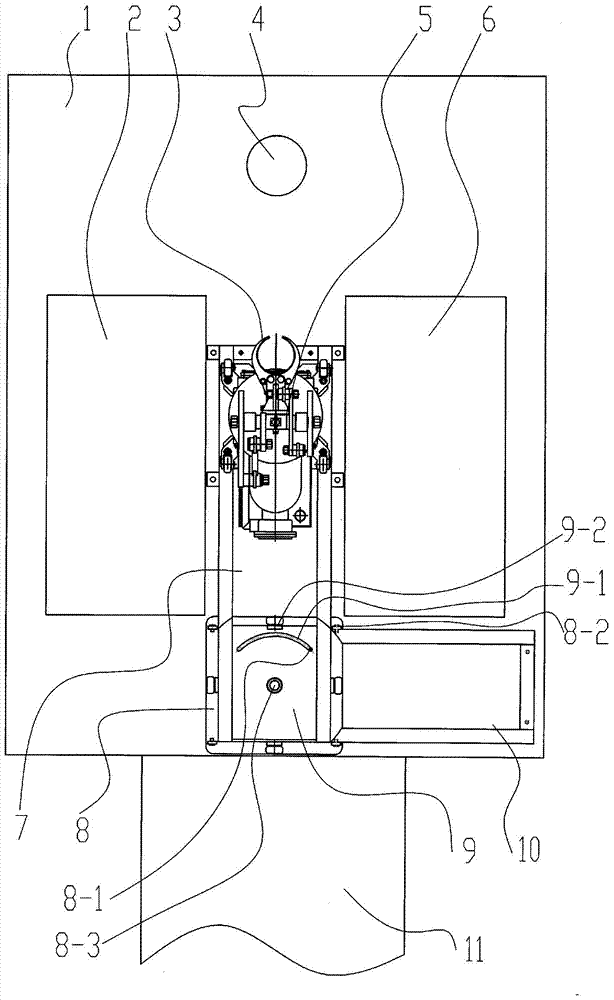

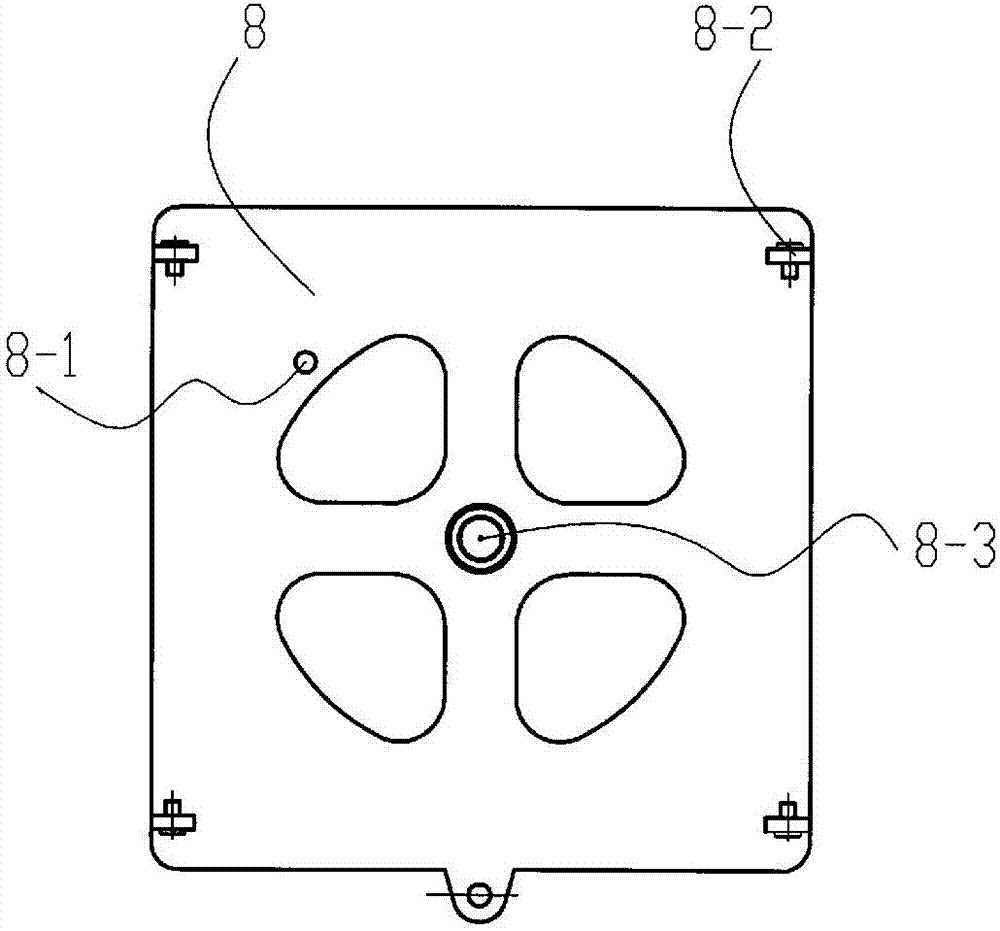

Movable drill pipe lay-down machine for oil field drilling and workover

ActiveCN106194068AEase of evacuationQuick evacuationDrilling rodsDrilling casingsSocial benefitsEconomic benefits

A movable drill pipe lay-down machine for oil field drilling and workover comprises a drilling and workover platform, a left drill pipe vertical storage box, a grabber, a lay-down machine body, a right drill pipe vertical storage box, a track frame, a track base, a rotary frame, a transfer track frame and a ramp. The lay-down machine body can travel from the track frame to the rotary frame and then travel from the rotary frame to the transfer track frame, and thus the lay-down machine body is evacuated conveniently, a construction passage is available, and other work can be performed conveniently. The left side and the right side of the track base are each provided with two flat clamping blocks. The transfer track frame can be conveniently dismounted from the right side of the track base and then installed on the left side of the track base. The drilling and workover platform can be arranged more reasonably, so that construction is facilitated. An elastic pressing device is installed behind the grabber, and grabbed drill pipes can be concentric with a borehole when the grabber is centralized. The lay-down machine body is evacuated conveniently and rapidly in a time and labor saving mode, working efficiency is high, the labor intensity of operators is relieved, the rescue passage can be available in time, blowout accidents are prevented, and economic benefits and social benefits are remarkable.

Owner:张成功

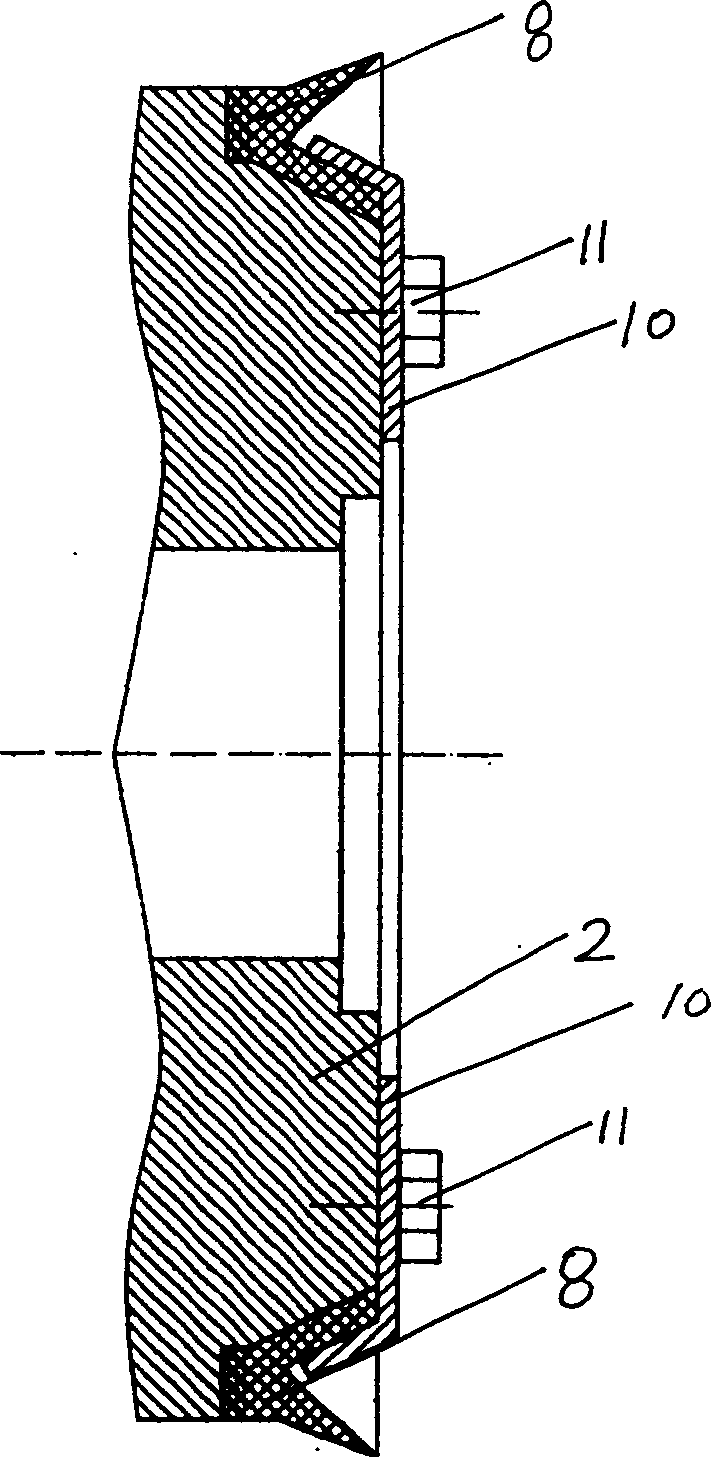

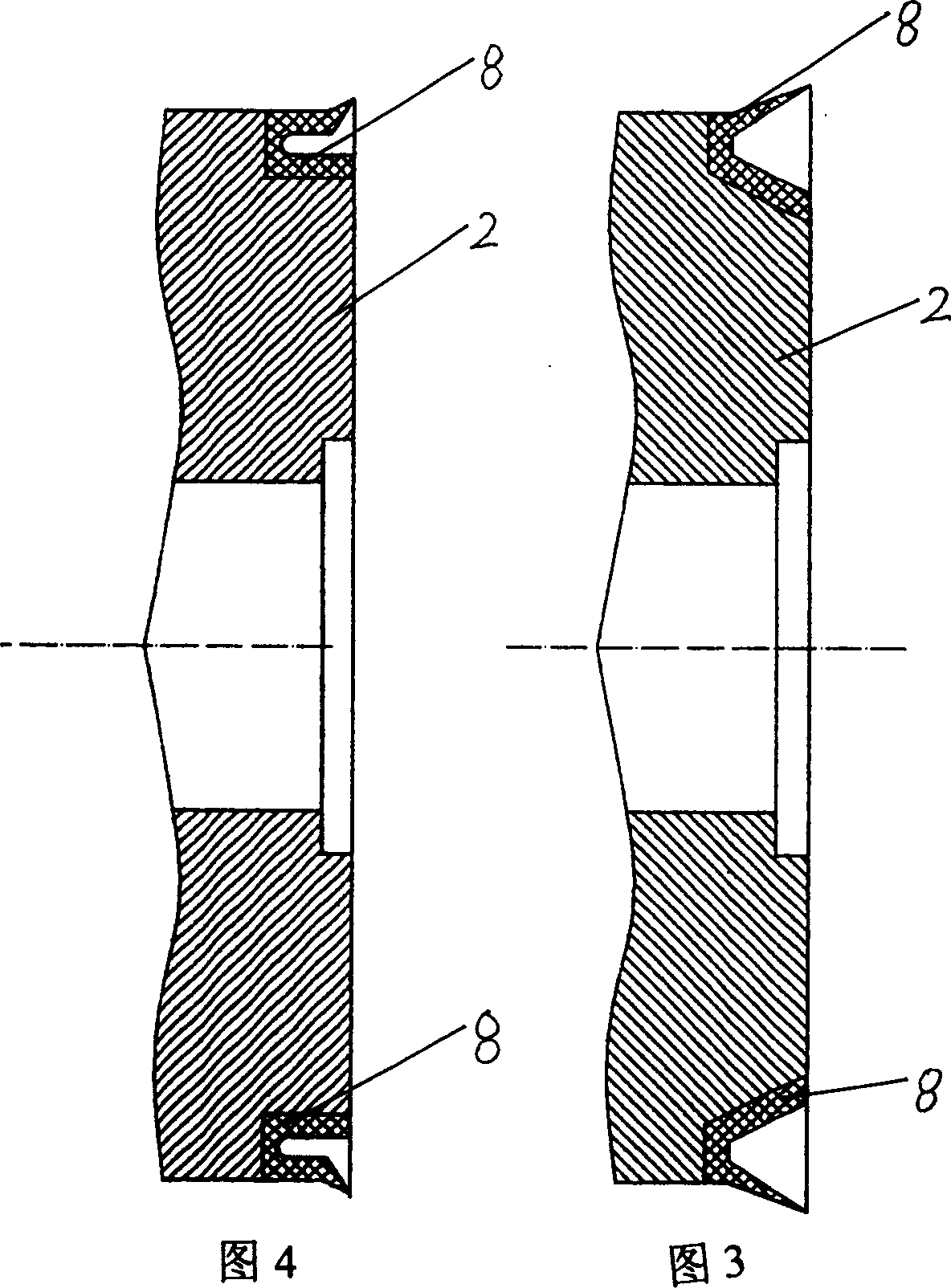

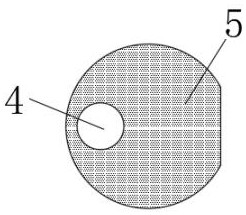

Well drilling pump piston

InactiveCN1590767AAvoid enteringEliminate water hammerPositive displacement pump componentsFluid removalRubber ringWell drilling

A piston for well-drilling pump is composed of main body, piston rod, sealing ring installed at front part of main body, the sealing ring positioned at the contact surface between main body and piston rod, and air blocking ring which is a V-shaped, trapezoidal or V-shaped rubber ring. Its advantages are no water hammer, and high sealing performance.

Owner:陈勇

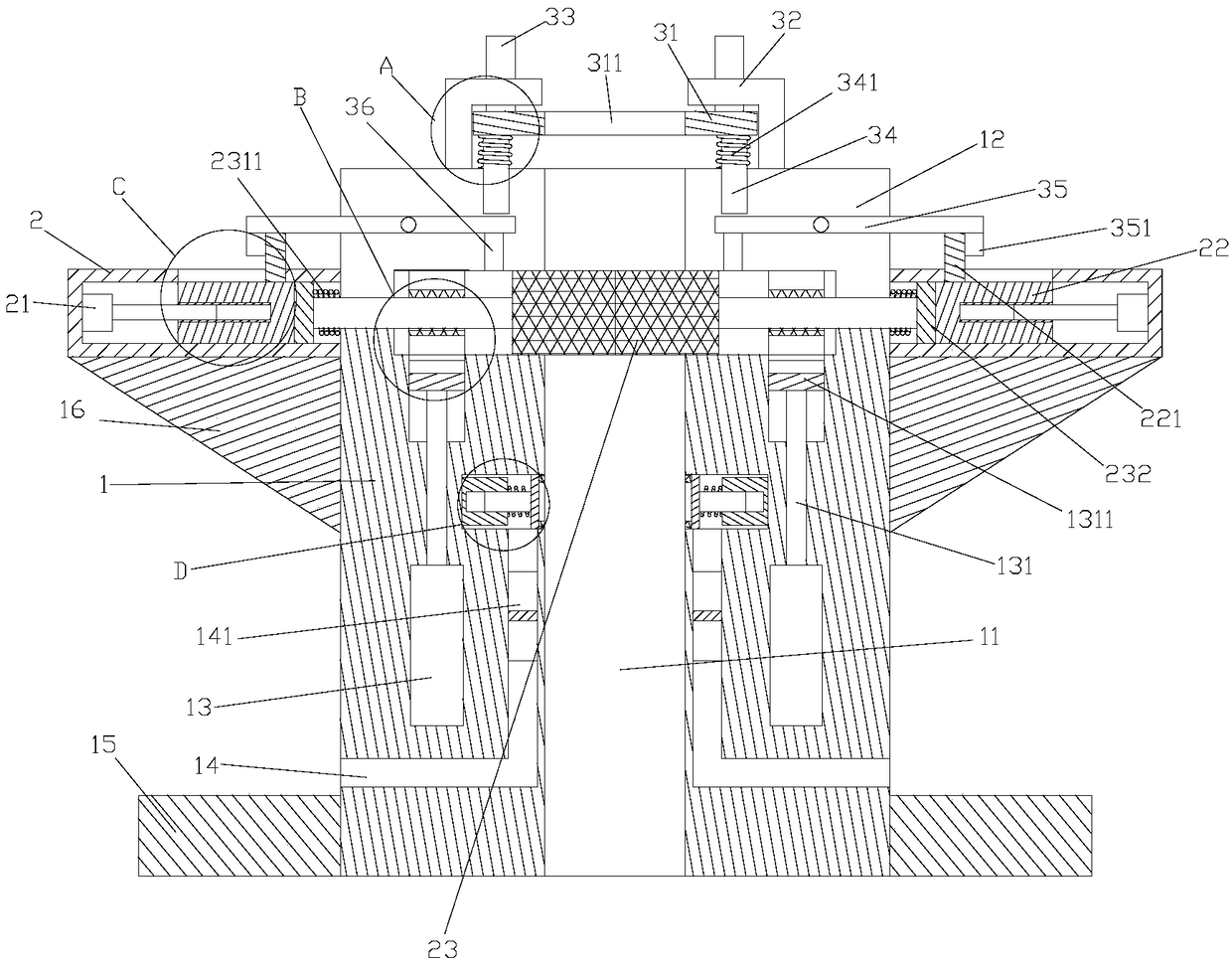

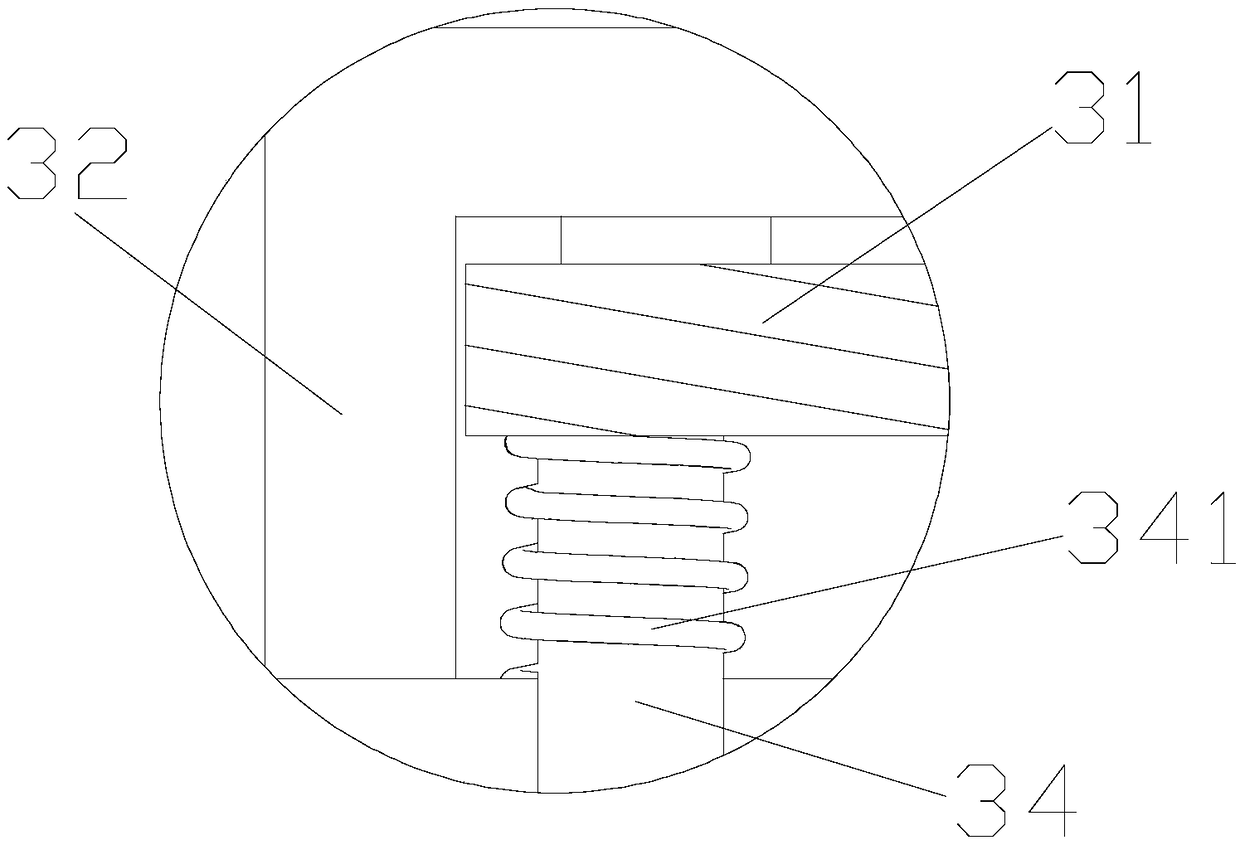

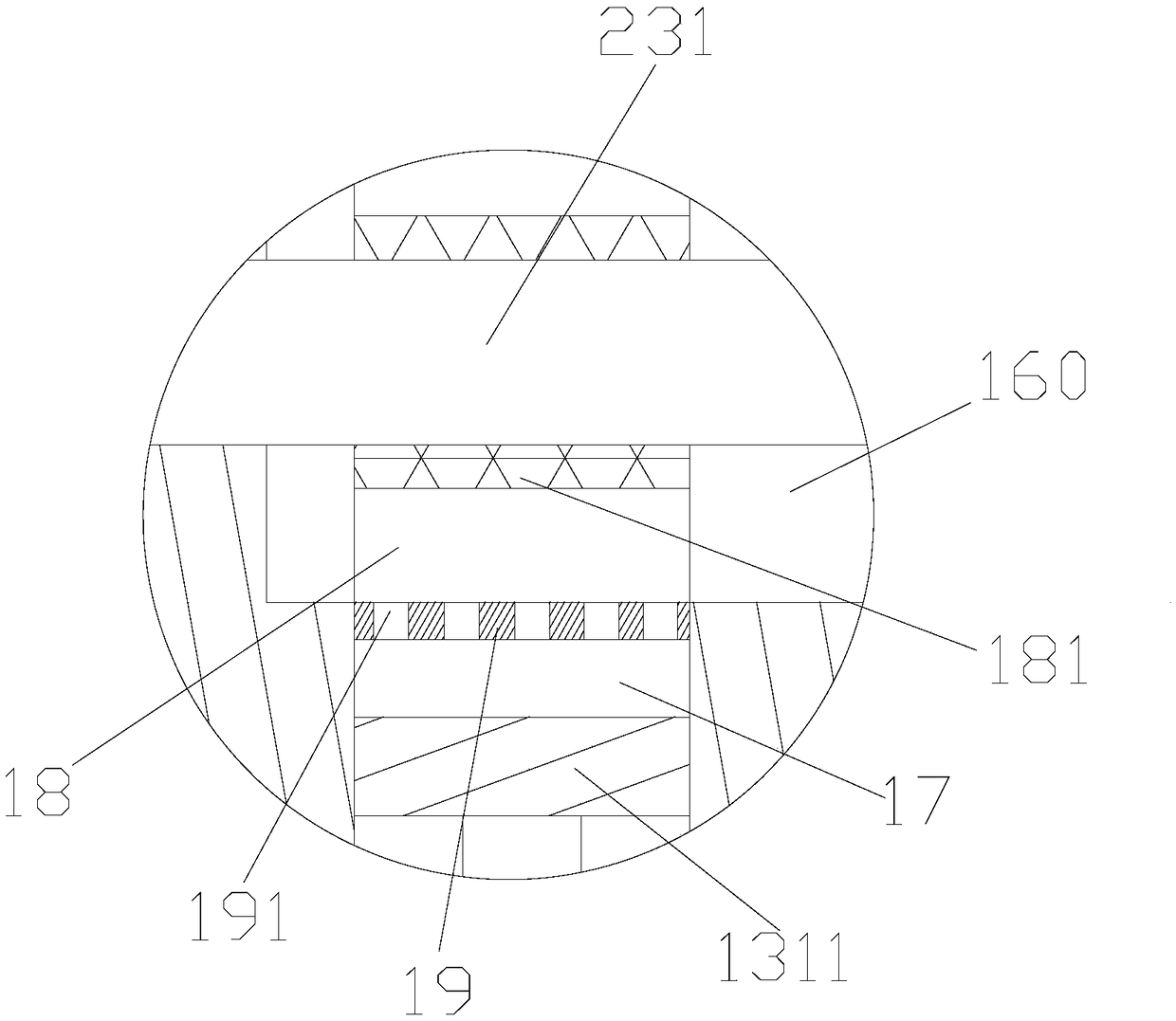

Blowout preventer

The present invention discloses a blowout preventer. The blowout preventer comprises a housing, fixed plates arranged at two sides of the housing and first device boxes arranged at the upper portionsof the fixed plates, the housing is internally provided with a first through hole, the first device boxes are internally provided with seal modules and drive parts configured to drive movement of theseal modules, the bottom portions of the first device boxes are provided with support bases; each seal module comprises one seal block, one connection rod fixedly connected with the seal block and onefirst push plate arranged at one end of the first connection rod; the housing is internally provided with a first movable cavity, the first connection rod penetrates the internal portion of the firstmovable cavity, and the seal blocks are arranged in the first through hole; and the first movable cavity is internally provided with a leakage-proof module. The drive parts in the device cavity drivethe seal modules to form a seal effect on the first through hole, the seal work of the blowout preventer can be completed through power itself to allow the blowout preventer to be more easily operated; and through mutual cooperation of the leakage-proof module and the seal modules, the seal effect of the blowout preventer is improved, and the generation of the blowout accident is avoided.

Owner:廊坊市荣亿石油开采技术服务有限公司

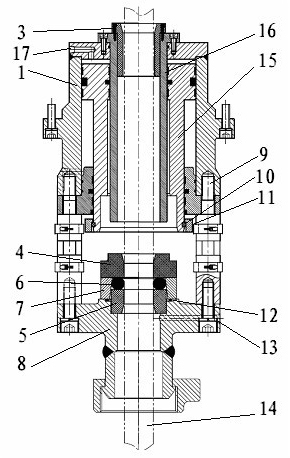

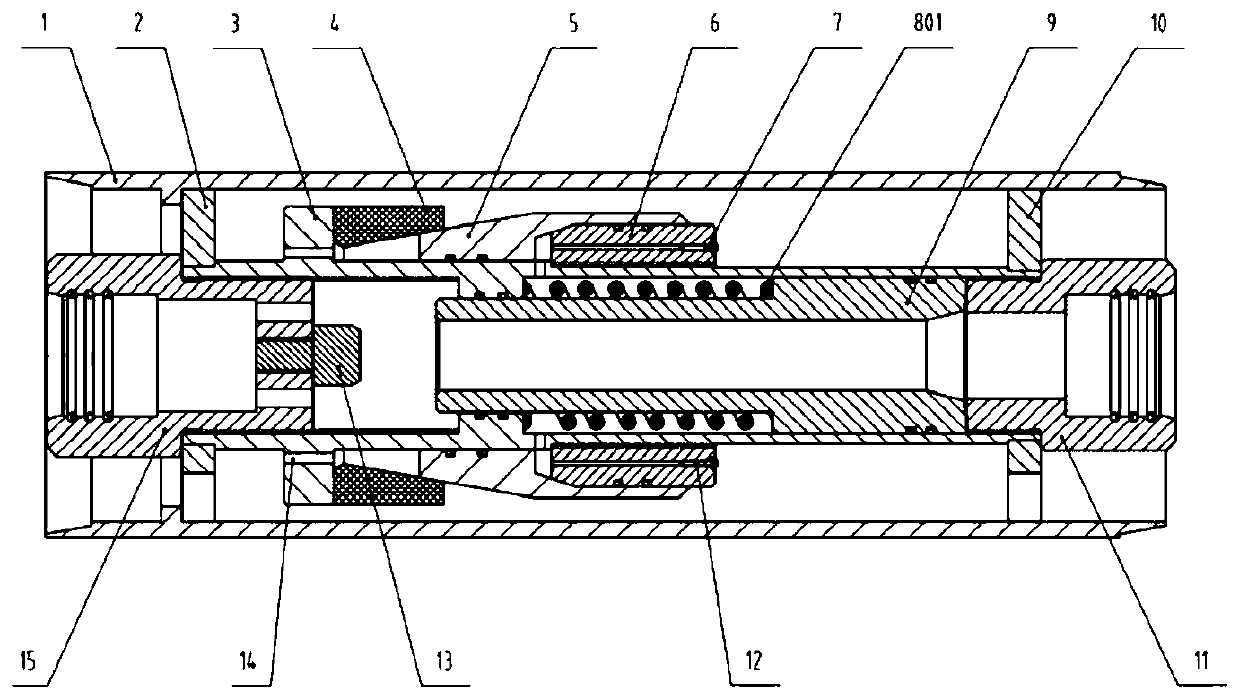

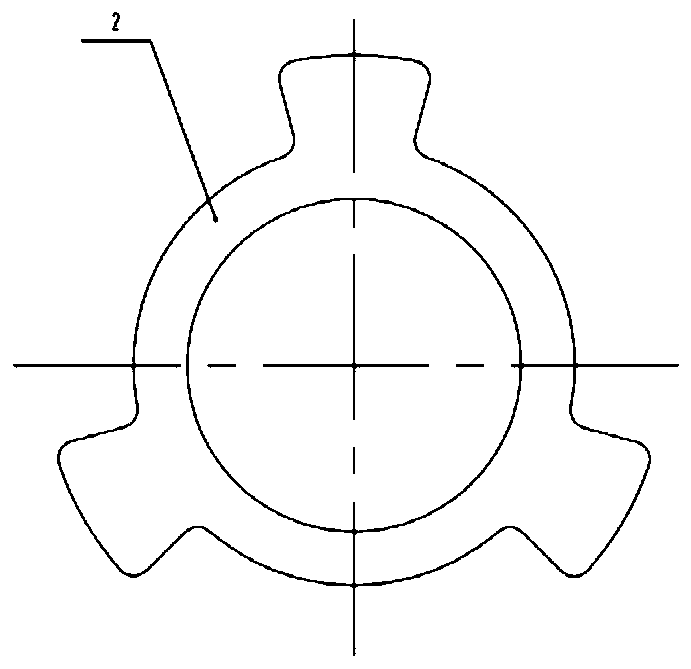

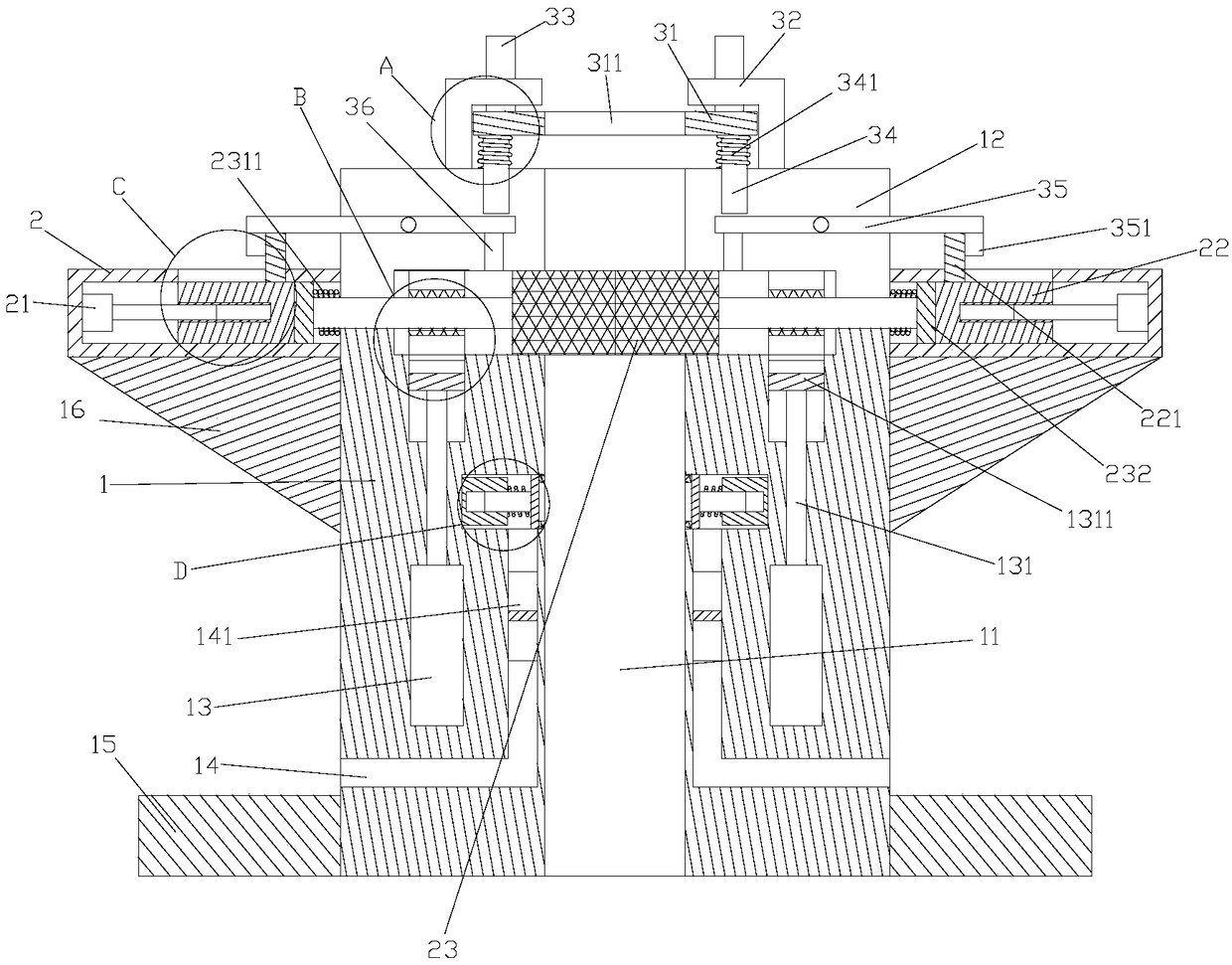

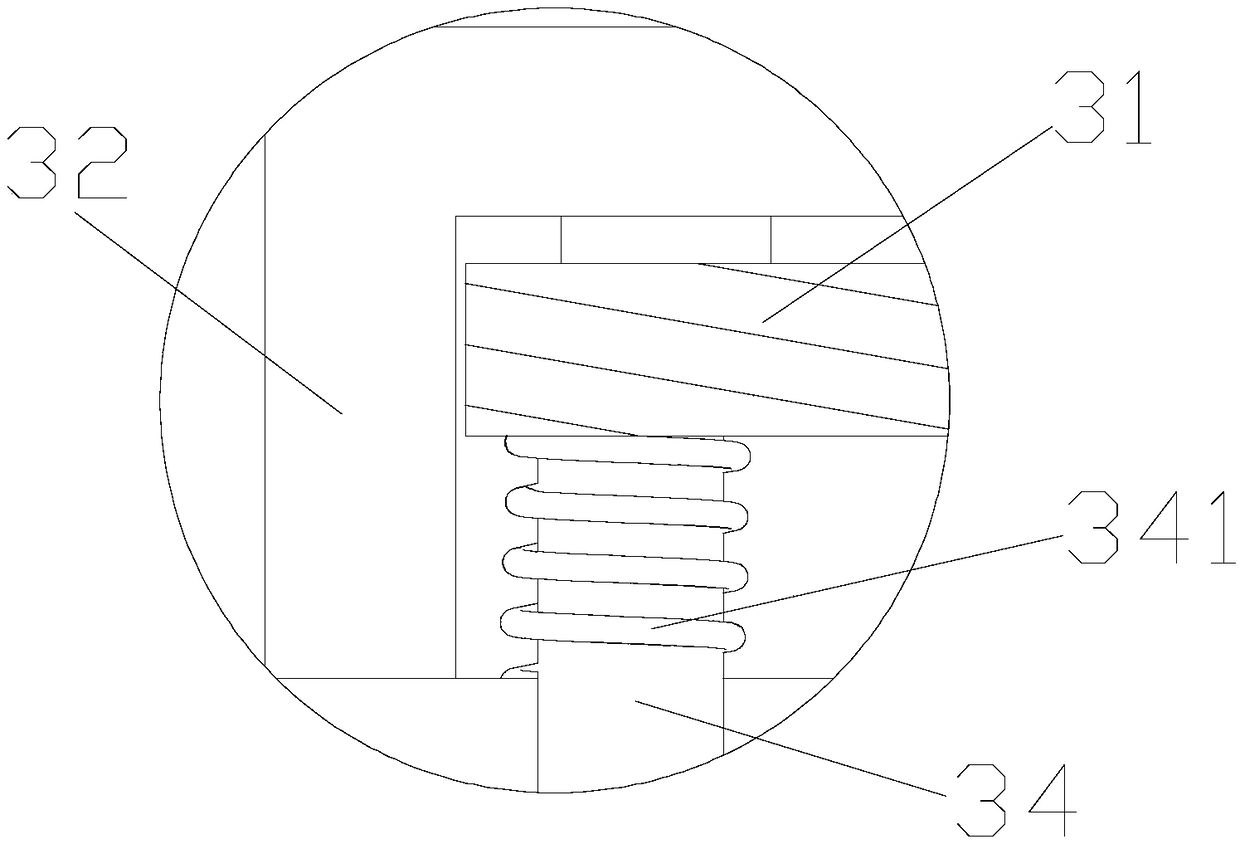

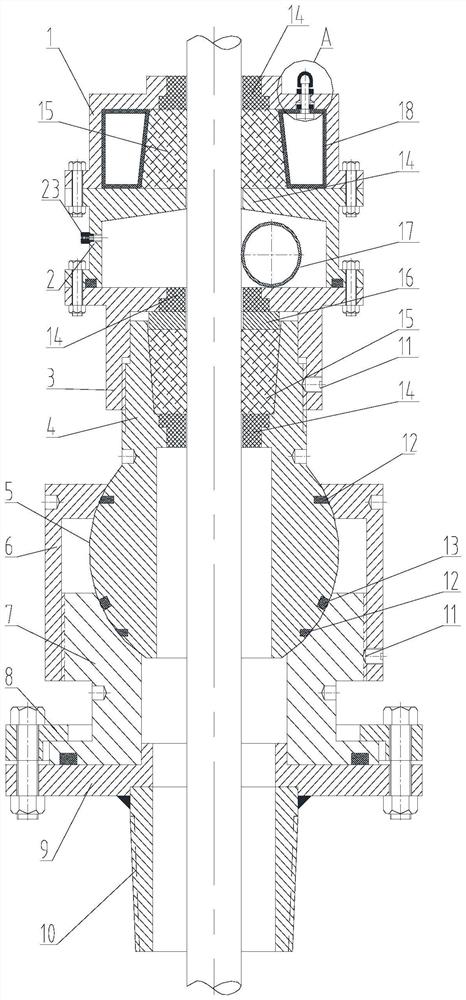

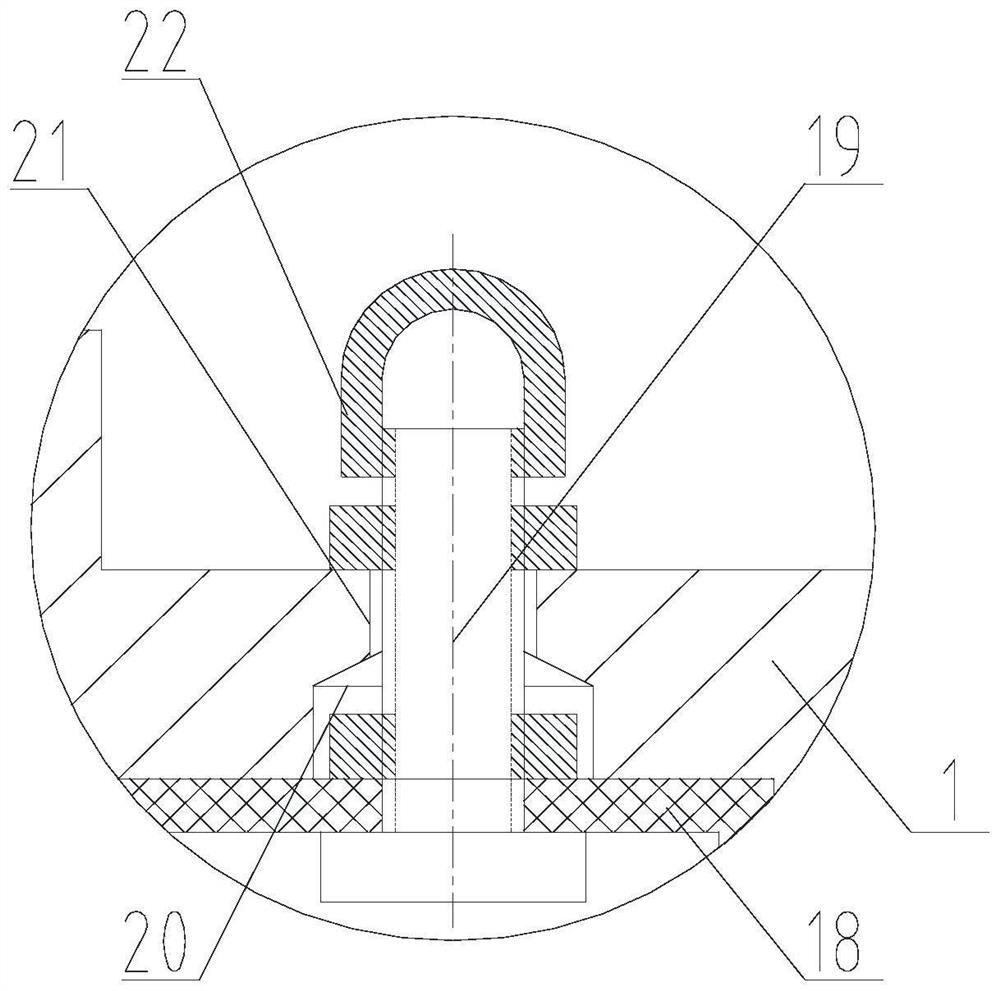

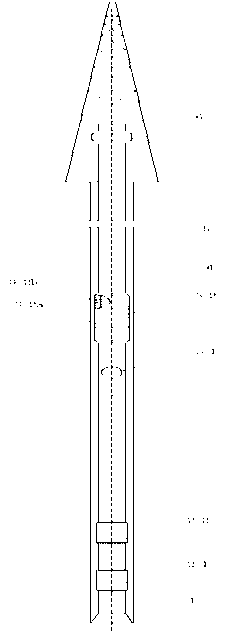

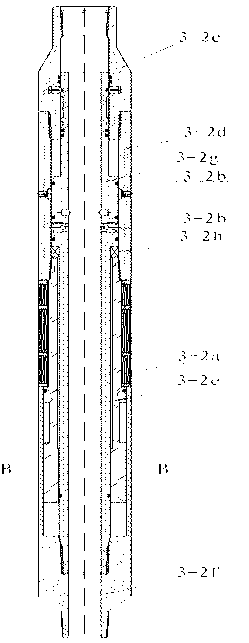

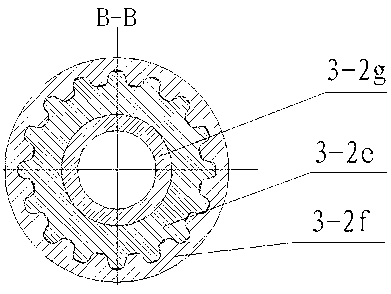

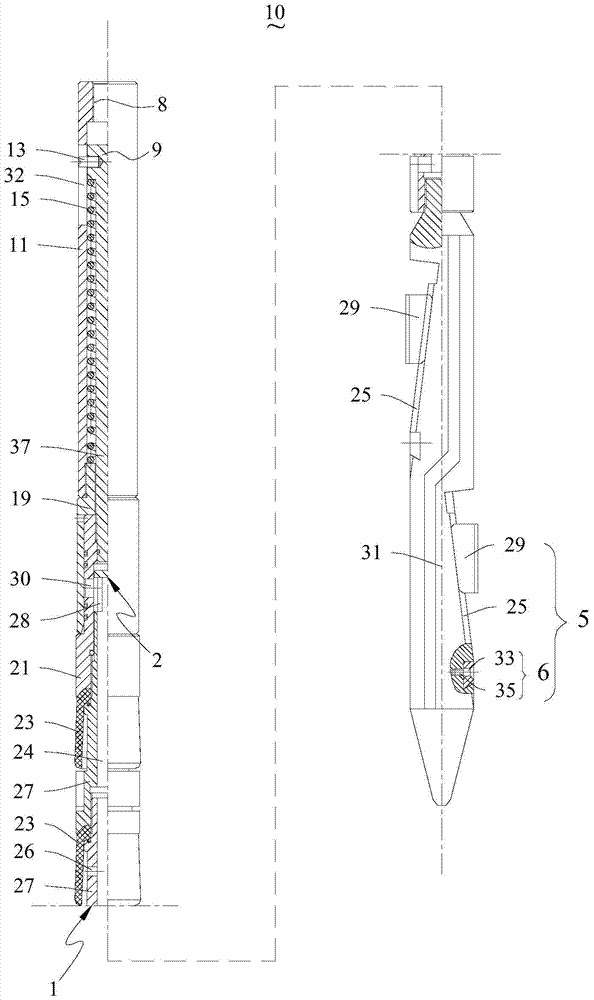

Motor-driven compressive rubber-barrel underground blowout preventer

The invention discloses a motor-driven compressive rubber-barrel underground blowout preventer and belongs to the technical field of underground blowout prevention. The motor-driven compressive rubber-barrel underground blowout preventer mainly comprises a control module, a power module, a communication module and an execution module. A rubber barrel of the execution module herein can be squeezedby a compression barrel, pushed by rotation of a motor, to expand, thereby sealing a shaft annulus; when unsealing is required, the motor rotates reversely to drive the compression barrel to move reversely, and the rubber barrel is released to allow unsealing. The motor-driven compressive rubber-barrel underground blowout preventer is reusable, can respond fast, is suitable for various well types,has good safety and reliability and long life, can be set to establish a new circulation passage between inner and outer annular spaces, thereby facilitating subsequent well killing.

Owner:SOUTHWEST PETROLEUM UNIV

Thermal recovery packing box with replaceable polish rod

The invention relates to the technical field of oil field equipment, in particular to a thermal recovery packing box with a replaceable polish rod. The packing box comprises a polish rod embracing seal body, the polish rod embracing seal body comprises an embracing seal shell, a seal assembly and an embracing assembly, two or more seal assemblies are distributed in the circumference of the embracing seal shell and can move inwards and outwards, when all the seal assemblies move to the inner end, the seal assemblies and the outer side of the polish rod can form seal, and two or more embracing assemblies are distributed in the circumference of the embracing seal shell and can move inwards and outwards. The arranged embracing assembly can clamp an outer annular groove in the polish rod, meanwhile, the upper end face of the outer annular groove of the polish rod can realize a securing effect when the polish rod is clamped, the arranged seal assemblies can seal the outer side of the polishrod to effectively prevent blowout accidents, kill fluid does not need to be injected, steam injection repetition is not needed, the temperature of a wellhead can be kept, the well-killing operation period can be shortened, cost can be lowered, and production efficiency can be improved.

Owner:KARAMAY SHENGLI PLATEAU MACHINERY CO LTD

Pneumatic isobaric multi-stage sealing device for wellhead of oil pumping unit

ActiveCN114673467ASave electricityLong sealing cycleDrilling rodsSealing/packingWellheadClose coupling

The invention discloses a pneumatic equal-pressure multi-stage sealing device for a wellhead of a pumping unit. Relates to the technical field of oil-gas well equipment. The lower end of the upper section is connected with the middle section through a flange and a bolt, the packing is clamped between the upper section and the middle section, and the air bag is installed in the space between the upper section and the middle section on the outer side of the packing. The device has the following beneficial effects that the air bag has an energy storage function, the packing is pressurized by continuous and uniform force, close coupling of the packing and a sucker rod is guaranteed, the hollow ball is arranged to be pushed to the center hole along the conical surface of the middle section by the pressure of the bottom of a wellhead after the rod is broken, blowout accidents are prevented, the deviation adjusting and follow-up function mechanism is automatically coaxial with the sucker rod, and the operation is convenient. The eccentric wear phenomenon is avoided, the service life of the packing and the sucker rod is prolonged, the sucker rod pushes the packing box through the centralizing sleeve, the deviation adjusting mechanism and the follow-up mechanism move flexibly along with the sucker rod, it is guaranteed that the follow-up mechanism and the sucker rod work coaxially all the time, eccentric wear is eradicated, and the service life of the sucker rod and the packing is prolonged.

Owner:DAQING DANNUO PETROLEUM TECH DEV

Blowout preventer facilitating fixation of oil delivery tube

ActiveCN109252826AImprove sealingAffect the connection effectSealing/packingDecompression tubesBiochemical engineering

The invention discloses a blowout preventer facilitating fixation of an oil delivery tube. The blowout preventer facilitating fixation of the oil delivery tube comprises a shell, fixing plates and a first equipment box, wherein the fixing plates are arranged on two sides of the shell; the first equipment box is arranged above the fixing plates; a first through hole is formed in the shell; a sealing assembly and a driving piece for driving the sealing assembly to move are arranged in the first equipment box; a supporting seat is arranged on the bottom of the first equipment box; a decompressionopening is formed in the inner wall of the first through hole; a decompression tube which is matched with the decompression opening is arranged in the shell; a fixing assembly is further arranged onthe inner wall of the first through hole; by the fixing assembly, the oil delivery tube which is inserted in the blowout preventer is fixed; and the oil delivery tube is prevented from vibrating during oil delivering, a connection effect of the oil delivery tube and the blowout preventer is affected, the airtightness of the blowout preventer is improved, and blowout accidents are avoided.

Owner:奥宸科技有限公司

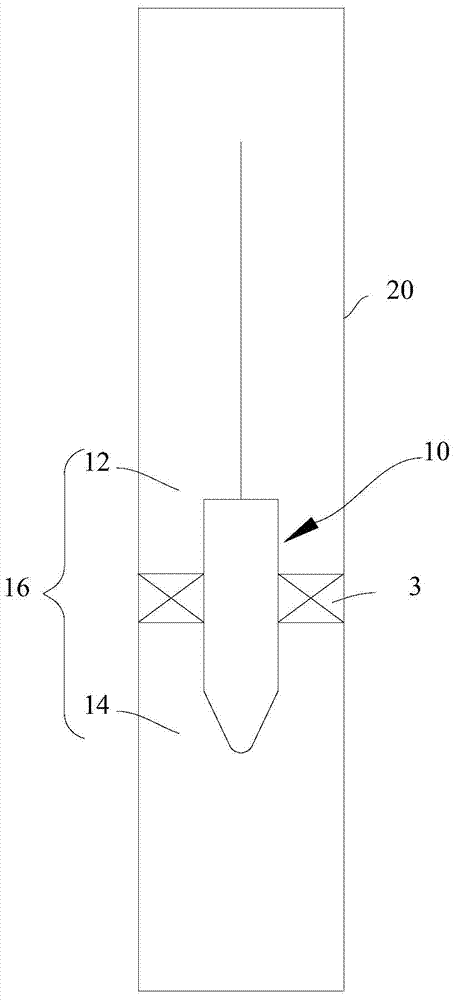

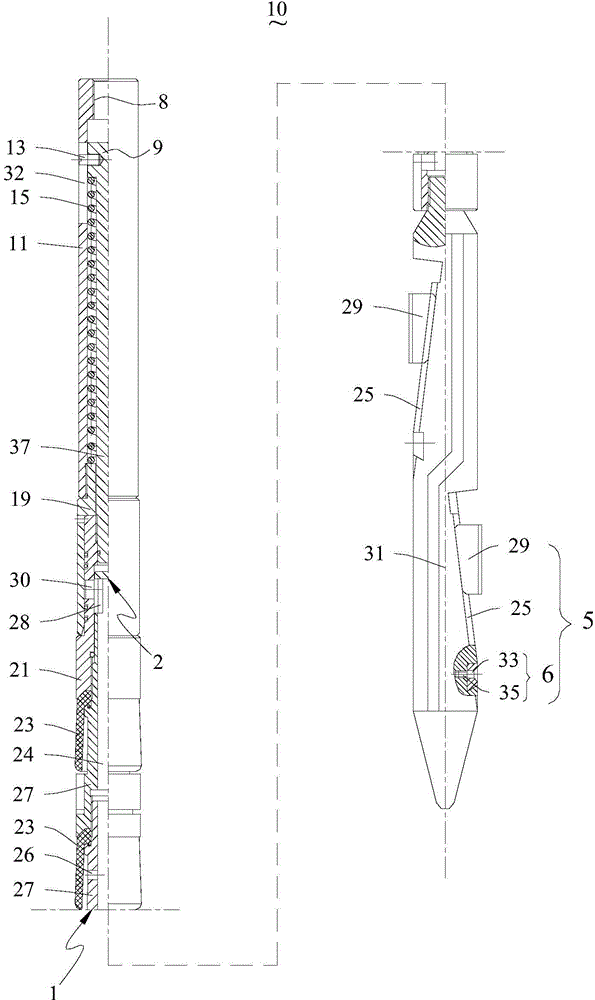

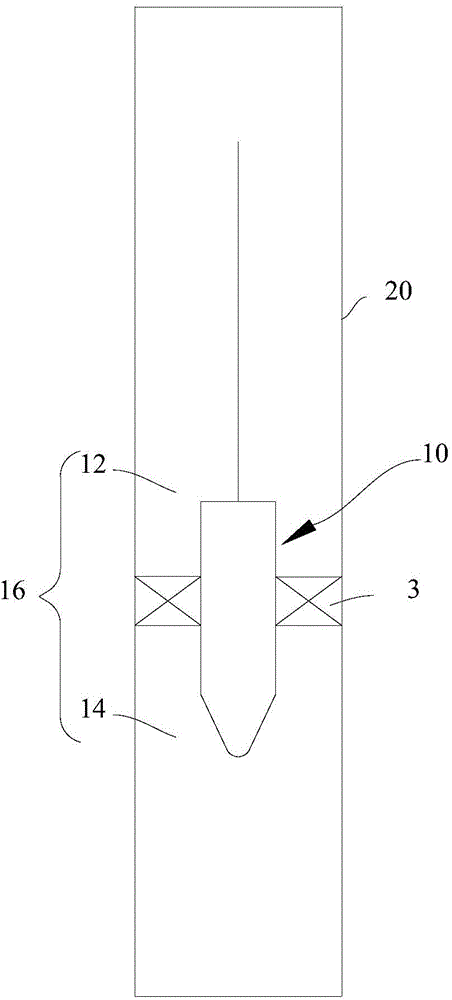

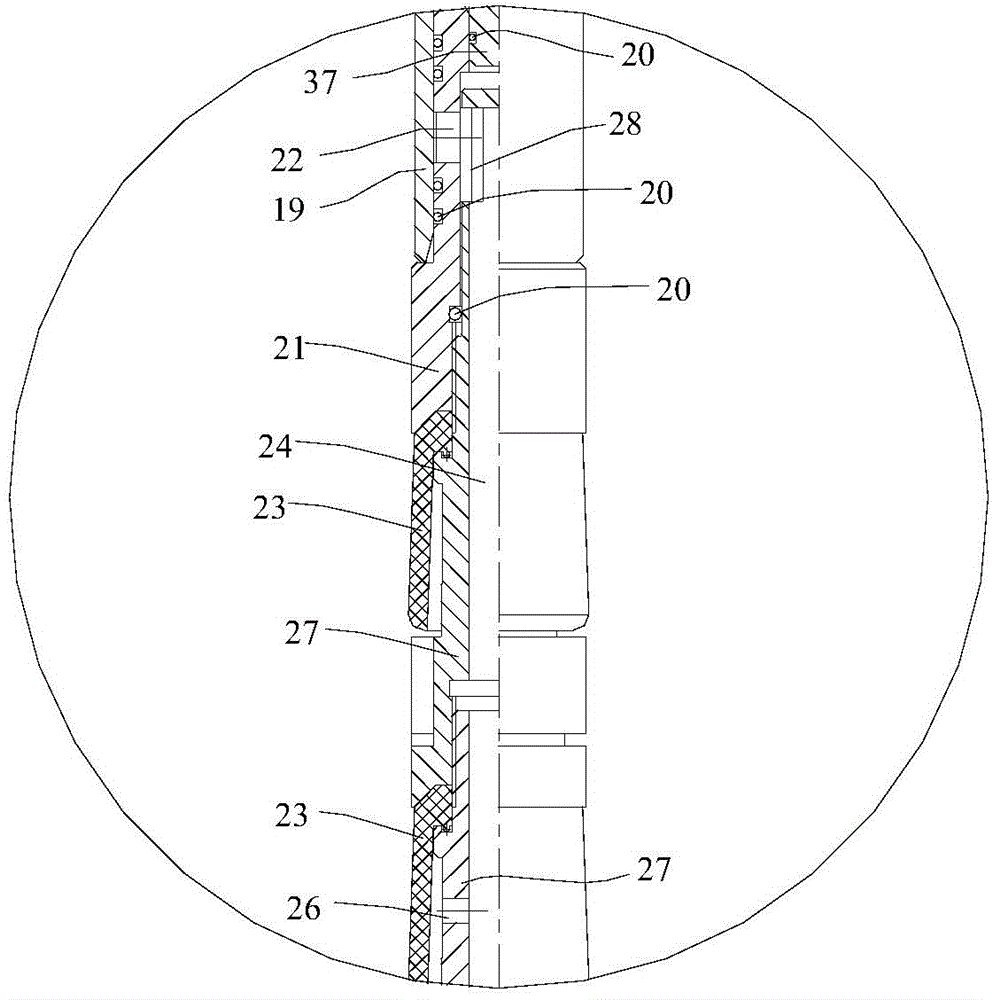

Drill string equipped with downhole blowout preventer and working method thereof

Owner:SOUTHWEST PETROLEUM UNIV

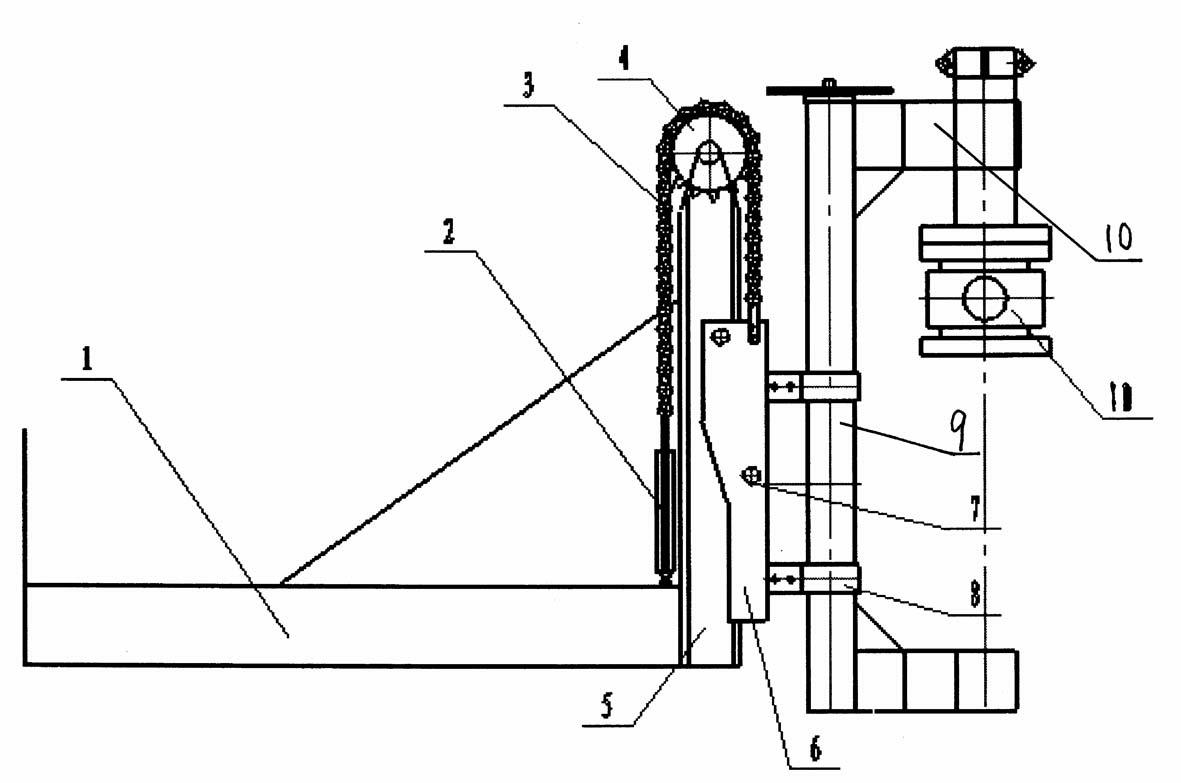

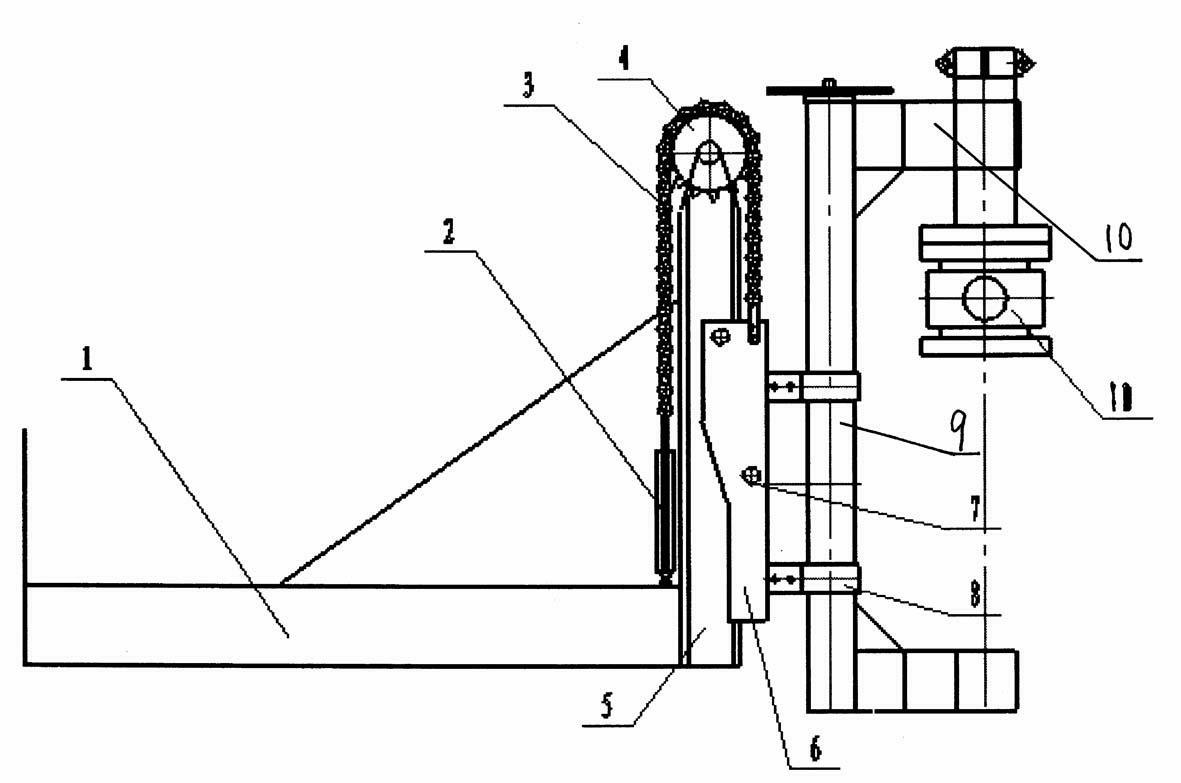

Device for quickly delivering tool for quickly spraying

InactiveCN102352729APrevent blowout accidentsReduce economic lossDrilling rodsSealing/packingPistonWellhead

The invention relates to a device for quickly delivering a tool for quickly spraying. The device a connection plate, a hydraulic cylinder assembly, a chain, chain wheels, a track bracket, an adjustment plate, a clamping hoop, a supporting frame, a cantilever beam and a tool for quickly spraying. The track bracket is vertically arranged on the connection plate; the lower part of the hydraulic cylinder assembly is fixed on the connection plate; the upper end of the track bracket is provided with the chain wheels; the chain is connected with the chain wheels; one end of the chain is connected with a piston arranged on the hydraulic cylinder assembly, and the other end of the chain is connected with the adjustment plate; the adjustment plate is arranged on the track bracket; the supporting frame is connected with the adjustment plate through the clamping hoop; the cantilever beam is arranged at the upper part of the supporting frame; the tool for quickly spraying is arranged on the cantilever beam; the connection plate is connected with original maneuvering equipment and can be quickly delivered to a wellhead by the maneuvering equipment; the maneuvering equipment can supply hydraulic sources to the hydraulic cylinder assembly, drive the adjustment plate to move up and down and adjust the device left and right. When used for quickly delivering the tool for quickly spraying, the device can conveniently, quickly, accurately and safely install the tool for quickly spraying in place. The device can be used for quickly installing wellhead control equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fracturing and sand prevention integrated process pipe column capable of preventing erosion and deeply backwashing well and operation method of fracturing and sand prevention integrated process pipe column

PendingCN114718473AReduce the risk of sand jamsPrevent blowout accidentsDrilling rodsFluid removalSand blastingOutfall

The invention provides a fracturing and sand prevention integrated process pipe column capable of preventing erosion and deeply backwashing a well and an operation method of the fracturing and sand prevention integrated process pipe column. A well control part comprises a safety valve with a valve clack, an upper hydraulic anchor and an annular packer, and an anti-erosion part comprises an upper sealing cylinder, a hollow insertion pipe and a lower sealing cylinder; the deep inverse well-flushing part comprises a deep well-flushing valve, a well-flushing differential pressure rupture disc, a well-flushing water outlet and an inserted seal in an oil pipe; and the separate-layer fracturing part comprises a Y344 packer, a ball-throwing sand-blasting sliding sleeve, a normally-open sand-blasting sliding sleeve, a lower hydraulic anchor and a check valve ball seat. By means of the method, fracturing and self-spraying production can be achieved through one pipe column, and the construction cost can be greatly reduced; a special safety valve protection mechanism is used, blowout accidents caused by erosion damage of a valve clack of the safety valve in the fracturing process are prevented, the deep well backwashing device is adopted to achieve well backwashing of the whole pipe column, and the risk that the pipe column is stuck by sand is reduced to the maximum extent.

Owner:CNOOC ENERGY TECH & SERVICES

plug

ActiveCN104879087BTo achieve the purpose of pressure reliefPrevent blowout accidentsWell/borehole valve arrangementsSealing/packingHigh pressureMechanical engineering

Owner:PETROCHINA CO LTD

Blanking plug

ActiveCN104879087ATo achieve the purpose of pressure reliefPrevent blowout accidentsWell/borehole valve arrangementsSealing/packingOperating pointEngineering

Owner:PETROCHINA CO LTD

A wellhead blowout prevention device

ActiveCN104806190BRealize the function of sealing and pluggingPrevent blowout accidentsSealing/packingBlowout preventerOil well

Owner:CHINA PETROLEUM & CHEM CORP

An oil production wellhead sealing protection device

The invention provides an oil production wellhead sealing protection device, which relates to the field of oil production. The wellhead sealing protection device for oil production includes a sealing seat, a polished rod vertically penetrates the middle part of the sealing seat, a pressure gauge is provided on one side wall of the middle part of the sealing seat, and a second sealing chamber is provided at the inner bottom of the second sealing cavity. Two sealing rings, the second sealing ring is arranged on the outer periphery of the polished rod, the inner middle part of the connecting seat and the polished rod form a first sealing cavity, the inner bottom of the first sealing cavity is provided with a first sealing ring, the Both sides of the middle part at the top of the connecting seat are fixedly connected to the collection tank by positioning pins, and the middle part of the collection tank is vertically penetrated with a polished rod. The spinning wheel is driven by the pole to press the second sealing ring, the injection pipe injects the sealant into the second sealing cavity, the pressure wheel improves the sealing between the first sealing ring and the connecting seat, and the triple seal makes the oil well head The sealing effect is good, and the cleaning effect on the polished rod can be realized through the collecting tank and the degreasing ring, which is worthy of vigorous promotion.

Owner:SHENGLI OILFIELD DONGFANG IND INVESTMENT GRP CO LTD +1

A multifunctional oil rod scraping and wax removal device

ActiveCN106368650BClear in timeAchieve the purpose of clearingDrilling rodsCleaning apparatusWaxPetroleum

The invention belongs to the technical field of mechanical accessories of oil wells, and discloses a multifunctional oil scraping and wax removing device for a sucker rod. The device structurally comprises a cylindrical casing which is matched with a well mouth of an oil well, can be fixed with the oil well and comprises an upper gland, wherein a wax and oil scraping mechanism assembly of the sucker rod is arranged in the cylindrical casing; a certain sliding clearance is formed between the cylindrical casing and the wax and oil scraping mechanism assembly of the sucker rod in a horizontal direction; corresponding sucker rod holes are formed in the upper gland and the bottom of the cylindrical casing; the sucker rod can penetrate through the corresponding sucker rod holes. According to the multifunctional oil scraping and wax removing device disclosed by the invention, wax oil on the sucker rod can be scraped, and the requirements on environment friendliness, engineering quality and safety production in an underground operation construction site of an oil industry are met; the multifunctional oil scraping and wax removing device has the characteristics of practicality, convenience in operation and simplicity in mounting and maintaining.

Owner:HEBEI HUAMENG MACHINERY MFG CO LTD

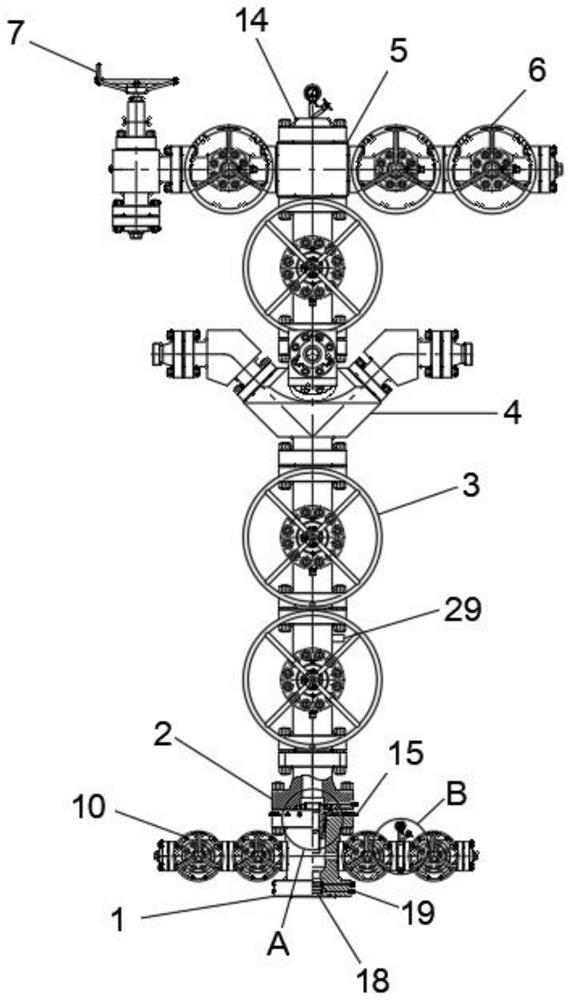

Fracturing pilot production composite wellhead device

InactiveCN114809984ALow costEasy to operateFluid removalWell/borehole valve arrangementsGate valvePetroleum engineering

The invention provides a fracturing pilot production composite wellhead device which comprises an oil pipe head, the top end of the oil pipe head is sequentially connected with a plurality of first flat gate valves through upper flanges, fracturing heads are arranged at the top ends of the first flat gate valves, and the top ends of the fracturing heads are connected with small four-way joints through the first flat gate valves. One end of the small four-way joint is connected with an adjustable throttling valve through a second flat gate valve, the other end of the small four-way joint is sequentially connected with a plurality of second flat gate valves, and a plurality of third flat gate valves are arranged on two sides of the tubing head respectively. The invention aims to provide the fracturing pilot production composite wellhead device which is safe, reliable and convenient to use.

Owner:YANCHENG XUDONG MASCH CO LTD

a blowout preventer

The present invention discloses a blowout preventer. The blowout preventer comprises a housing, fixed plates arranged at two sides of the housing and first device boxes arranged at the upper portionsof the fixed plates, the housing is internally provided with a first through hole, the first device boxes are internally provided with seal modules and drive parts configured to drive movement of theseal modules, the bottom portions of the first device boxes are provided with support bases; each seal module comprises one seal block, one connection rod fixedly connected with the seal block and onefirst push plate arranged at one end of the first connection rod; the housing is internally provided with a first movable cavity, the first connection rod penetrates the internal portion of the firstmovable cavity, and the seal blocks are arranged in the first through hole; and the first movable cavity is internally provided with a leakage-proof module. The drive parts in the device cavity drivethe seal modules to form a seal effect on the first through hole, the seal work of the blowout preventer can be completed through power itself to allow the blowout preventer to be more easily operated; and through mutual cooperation of the leakage-proof module and the seal modules, the seal effect of the blowout preventer is improved, and the generation of the blowout accident is avoided.

Owner:廊坊市荣亿石油开采技术服务有限公司

A movable drill pipe discharger for oil field drilling and workover

ActiveCN106194068BEase of evacuationQuick evacuationDrilling rodsDrilling casingsSocial benefitsEconomic benefits

A movable drill pipe lay-down machine for oil field drilling and workover comprises a drilling and workover platform, a left drill pipe vertical storage box, a grabber, a lay-down machine body, a right drill pipe vertical storage box, a track frame, a track base, a rotary frame, a transfer track frame and a ramp. The lay-down machine body can travel from the track frame to the rotary frame and then travel from the rotary frame to the transfer track frame, and thus the lay-down machine body is evacuated conveniently, a construction passage is available, and other work can be performed conveniently. The left side and the right side of the track base are each provided with two flat clamping blocks. The transfer track frame can be conveniently dismounted from the right side of the track base and then installed on the left side of the track base. The drilling and workover platform can be arranged more reasonably, so that construction is facilitated. An elastic pressing device is installed behind the grabber, and grabbed drill pipes can be concentric with a borehole when the grabber is centralized. The lay-down machine body is evacuated conveniently and rapidly in a time and labor saving mode, working efficiency is high, the labor intensity of operators is relieved, the rescue passage can be available in time, blowout accidents are prevented, and economic benefits and social benefits are remarkable.

Owner:张成功

Blowout preventing box of continuous oil pipe and drill rod

The invention discloses a blowout preventing box of a continuous oil pipe and a drill rod. The blowout preventing box comprises a hollow hydraulic cylinder and a flange union connected through connecting rod bolts, and a set of valve assembly is arranged on the two connecting rod bolts opposite in the diameter direction respectively; the hollow hydraulic cylinder is arranged at a hydraulic inlet / outlet; a fixed sleeve is arranged in the cavity of the hollow hydraulic cylinder, an upper guide sleeve is sleeved at the upper end of the inner wall of the fixed sleeve, the upper guide sleeve and the interior of the flange union axially pass through the continuous pipe, a piston rod is arranged between the fixed sleeve and the hollow hydraulic cylinder, and the inner circumference of the lower section of the piston rod is provided with a seam allowance; and a middle guide sealing pressing sleeve and an inner cone guide spacing ring are sleeved on the inner circumference of the seam allowance, the inner circumference of the middle guide sealing pressing sleeve is sleeved with the continuous pipe, a main sealing ring and a lower guide sealing pressing sleeve are arranged between the inner cone guide spacing ring and the continuous pipe, and a hydraulic detection port is bypassed in the radial direction of the flange union. The pressure adjustment of the sealing cavity is convenient; time and labor are saved when the sealing ring is replaced; and the pressure of a wellhead can be detected in real time.

Owner:BAOJI PETROLEUM MASCH CO LTD

Oil well broken rod blowout preventer

The invention discloses an oil-well broken rod blowout preventer which comprises a shell docked with a packing box. A through hole in which an unthreaded pole penetrates is formed in the shell, a sealing cavity communicated with the through hole is formed inside the shell, a steel ball used for sealing the through hole is arranged inside the sealing cavity, a first elastic piece used for popping up the steel ball is arranged in the sealing cavity in the rear of the steel ball, and a control device used for preventing the steel ball contacting with the unthreaded pole during normal operating of the unthreaded pole is arranged in the shell. The oil-well broken rod blowout preventer has the advantages that since the steel ball is prevented from contacting with the unthreaded pole during normal operating of the unthreaded pole, the sealing steel ball or the unthreaded pole is effectively prevented from abrasion, and service life of the unthreaded pole is guaranteed; the control device is capable of effectively enabling the steel ball to seal an oil duct in case of fracture of the unthreaded pole, so that well blowout accidents are prevented.

Owner:段鹏飞 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com