Blow-out prevention valve in double-layer pipe

A technology of internal blowout prevention and double-layer pipes, which is applied in the direction of wellbore/well valve device, wellbore/well components, sealing/isolation, etc., can solve problems such as inability to achieve effective control, and improve drilling efficiency, The effect of saving time and preventing well kick or blowout accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

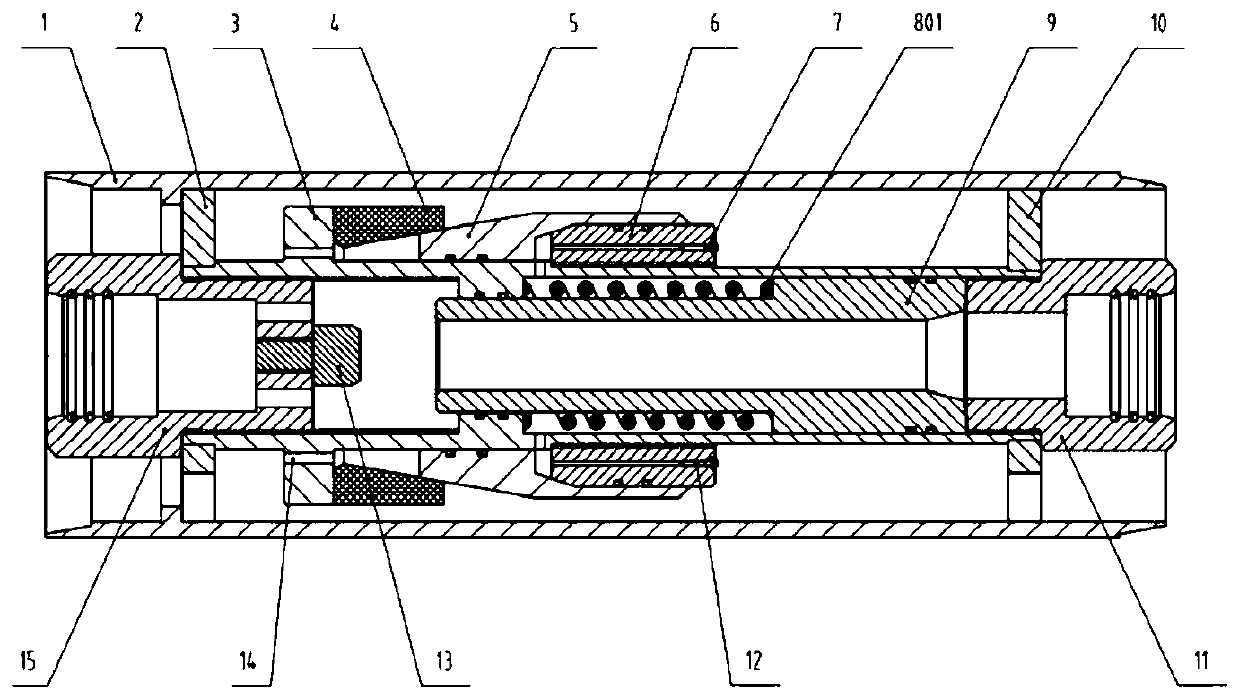

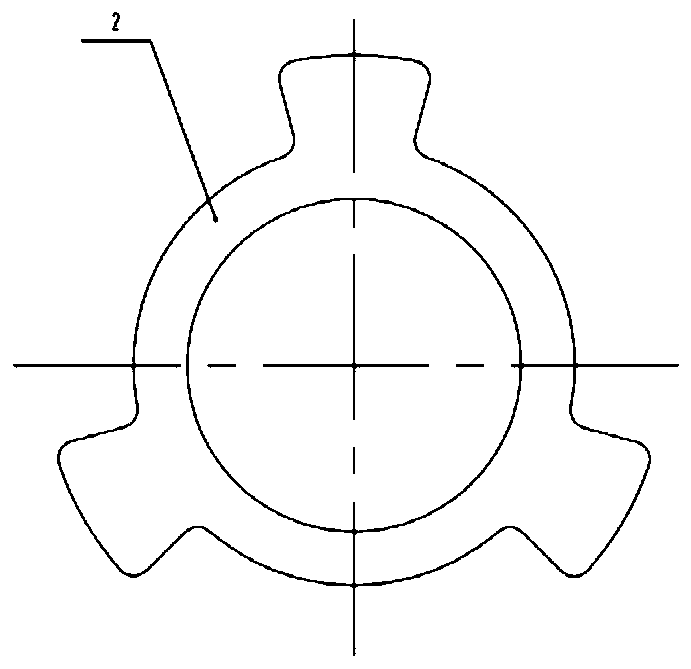

[0021] Embodiment 1 of a double-layer pipe blowout preventer valve, such as figure 1 As shown, the device includes a rubber core 4, a piston 5, a valve seat 6, a differential pressure sliding sleeve 9, a support plate, an inner pipe 3, an outer pipe 1, an upper joint 15 of the inner pipe and a lower joint 11 of the inner pipe; The differential sliding sleeve 9 is located in the inner tube cavity, and its initial position is pushed against the lower joint 11 of the inner tube by the elastic force of the spring 801; the rubber core 4 and the piston 5 are located on the outer wall of the inner tube 3, and the rubber core 4 is placed in turn On the outer step of the inner pipe, put the piston 5 into it and finally fix it by the threaded cooperation between the valve seat 3 and the inner pipe; the outer step of the inner pipe is arranged with 6 pressure relief ports 14 along the circumference for discharging the rubber core 4, The drilling fluid in the cavity formed by the piston 5...

Embodiment 2

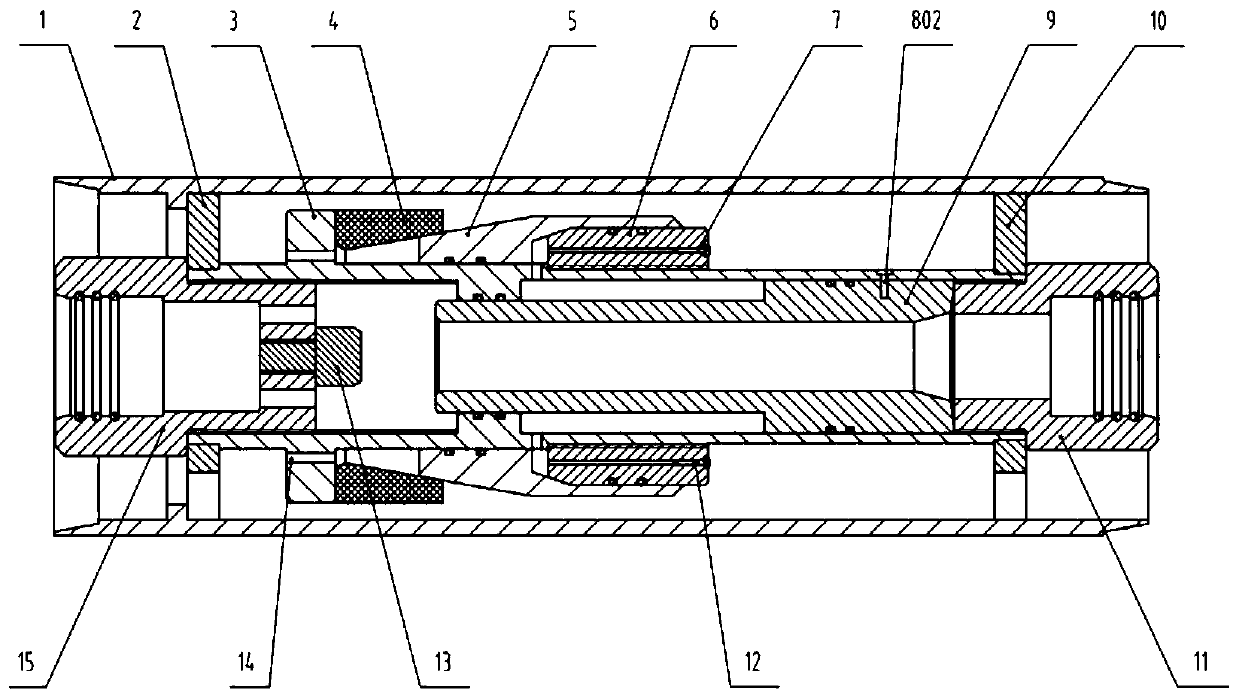

[0027] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that image 3 As shown, in this embodiment, the shear pin 802 is used to replace the spring 801 to position the initial position of the differential pressure sleeve 9. When a well kick or blowout occurs, the high-pressure fluid pushes the differential pressure sleeve 9 to move the shear pin 802 Cut off, so that the pressure differential sliding sleeve 9 cooperates with the plugging block 13 to close the inner tube 3. After using the shear pin 802, the tool cannot be opened by itself. It is necessary to lift the tool out of the well, replace the shear pin 802, and run it again.

[0028] Other structural principles and motion processes of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com