A wellhead blowout prevention device

A blowout preventer, blowout preventer technology, applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve problems such as oil and gas leakage at the wellhead, prevent blowout accidents, reduce environmental protection costs, reduce The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

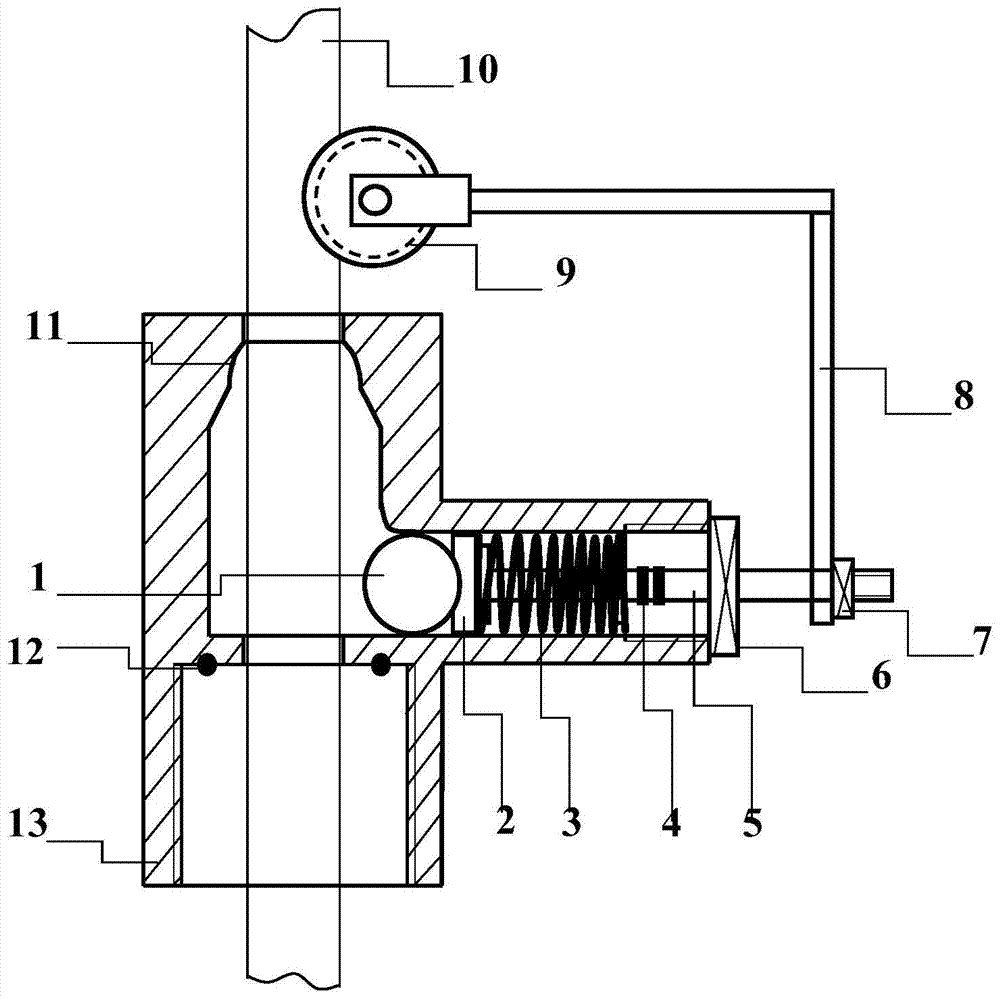

[0021] see figure 1 , is a schematic structural view of the wellhead blowout preventer in the present invention, as figure 1 As shown, the wellhead blowout preventer of the present invention is installed on the blowout preventer box of the polished rod sealer. The wellhead blowout preventer of the present invention includes a body 13, the polished rod 10 can pass through the body 13, and the inside of the body 13 is also provided with a The sealing ball 1 of the polished rod hole in the body 13 is provided with a thrust device against the outer surface of the polished rod 10 outside the body 13. The thrust device can push the sealing ball against the polished rod hole in the body when the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com