a blowout preventer

A blowout preventer and casing technology, which is applied in wellbore/well components, sealing/package, earthwork drilling and production, etc., can solve the problems of high sealing requirements at the connection of gas pumps and inconvenient operation, and achieve easy operation , Increase the sealing effect and prevent blowout accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

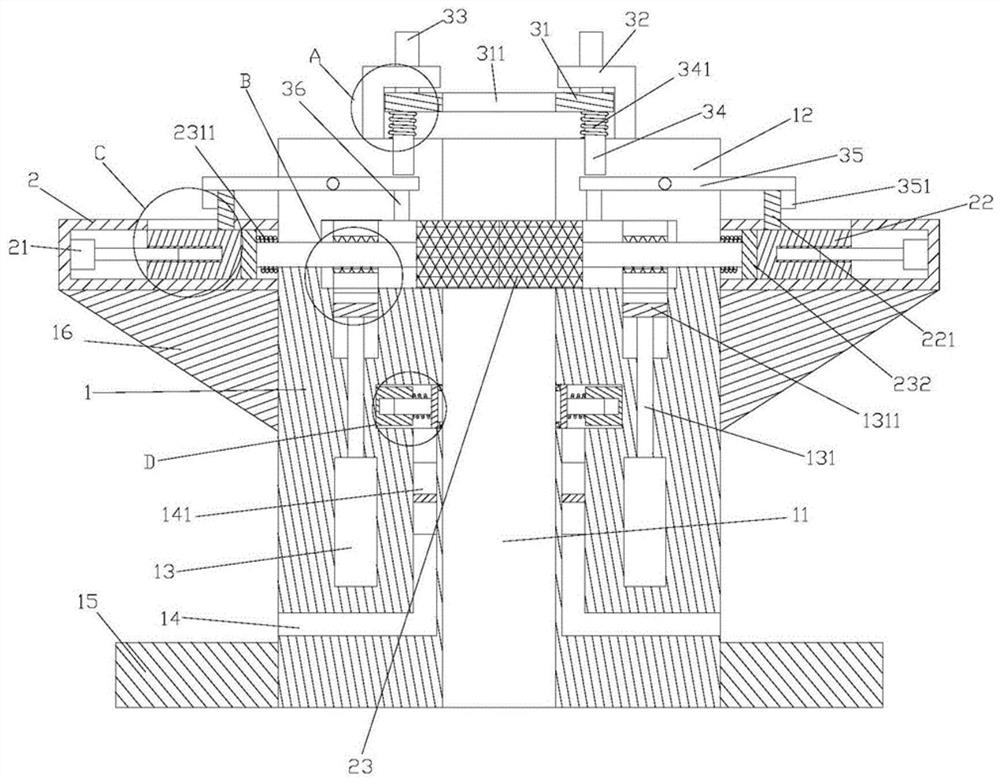

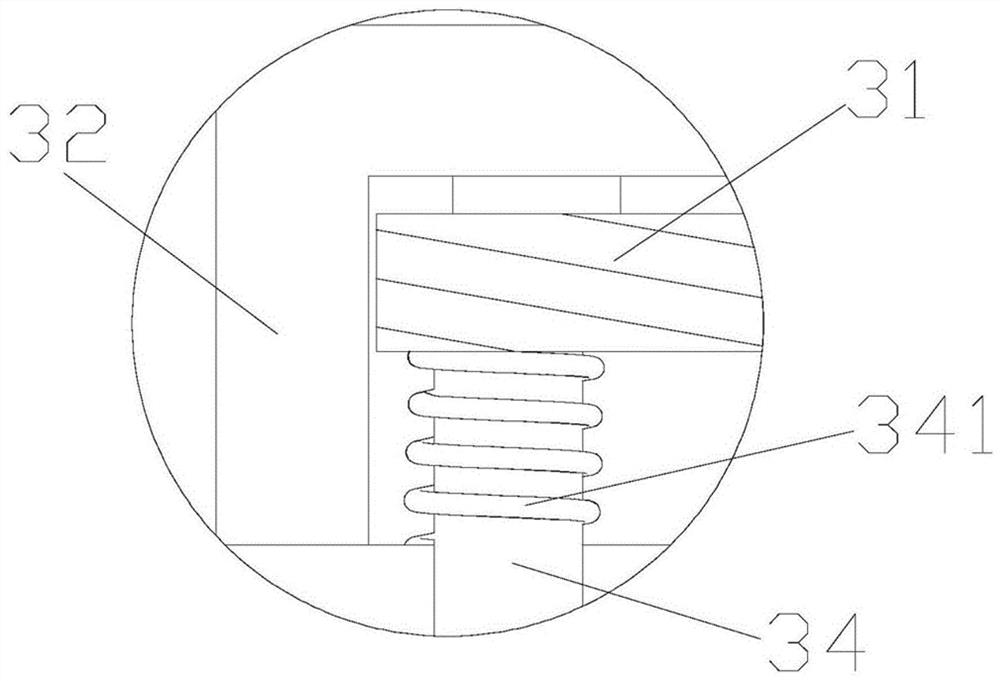

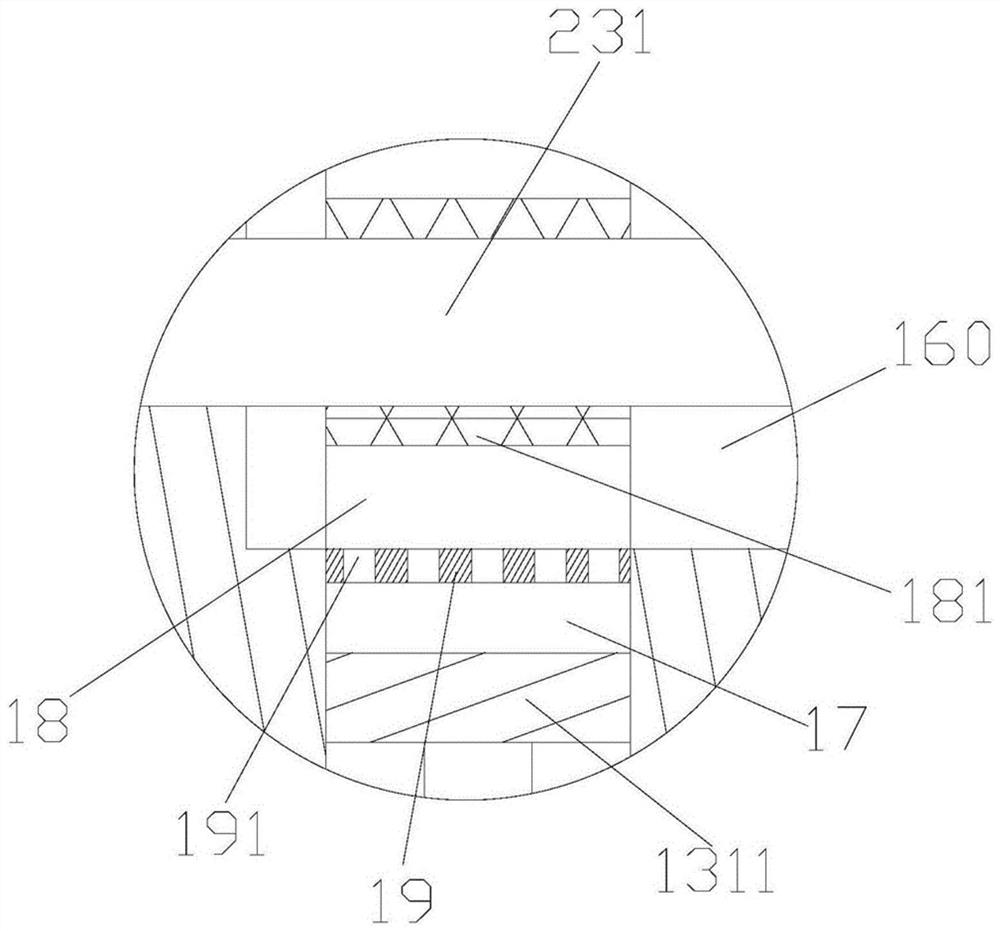

[0029] Such as Figure 1-7 As shown, a blowout unit includes a housing 1, a fixing plate 15 disposed on both sides of the housing 1 and a first equipment case 2 disposed above the fixing plate 15, and the first equipment box 2 is two. The group, respectively, sides of the housing 1, and the fixing plate 15 is used to secure the blowout unit to the wellhead, so that the blowout unit can act as a sealing of the oil well; the casing 1 is provided with a first through hole 11 The oil pipe can be inserted into the oil well from the first through hole; the first equipment case 2 is provided with a sealing assembly and a driving member for driving the sealing assembly; the first equipment box 2 The support seat 16 is provided at the bottom; the support seat 16 is provided as a triangular structure, and the first equipment box is fixed to the sidewall of the housing by the principle of triangular stability; the sealing assembly includes a sealing block 23, with the sealing block 23. The fi...

Embodiment 2

[0040] Such as Figure 8-10 As shown, the difference from the first embodiment is that the fixing plate 15 is provided with a fixture, the fixing device to be detachably connected to the fixing plate 15; a fixed device is fixed, an increase The fixing effect of the anti-blower enables the blowout unit to be more stable in the wellhead, which acts as a well preventive well-fitting effect; through the detachable connection of the fixture and the fixed plate, convenient to repair and maintenance of the fixing device, extend the fixed The service life of the device.

[0041] The fixture includes a second equipment tank 4 disposed on the fixing plate 15, a hydraulic cylinder 41 disposed within the second equipment tank 4, a rotary electric machine 44, a hydraulic cylinder 41 piston rod, and The positioning drill bit 45 is provided on the output shaft of the rotating motor 44; the piston rod of the hydraulic cylinder is inserted into the second device box, and the rotary electric machin...

Embodiment 3

[0045] Such as Figure 11-12 As shown, the difference between the present embodiment and the first embodiment is that the inner wall of the first through hole 11 is also provided with a fixed assembly; the oil pipe inserted into the blower inserted into the blower is fixed by a fixed component to avoid the oil pipe in oil. Generating vibration, affecting the connection effect of the oil pipe and the anti-blower, enhance the sealing of the anti-sprayer, and avoids the occurrence of blowout accidents.

[0046] The fixing assembly includes a second mounting plate 5 disposed on the inner wall of the first through hole 11, a connection spring 54 disposed on the second mounting plate 5 and a fastening that is secluded on the connection spring 54. The plate 51; the fixing assembly is two groups, respectively, on both sides of the inner wall of the first through hole, and the oil pipe is inserted into the first via hole, and the oil pipe is placed between the left and right fastening plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com