Anti-spraying device for while drilling

A blowout prevention device and drilling-while-drilling technology, which is applied to wellbore/well valve devices, earthwork drilling, wellbore/well components, etc., can solve problems such as improper operation by operators, blowout accidents, occurrences, etc., and avoid operation The effect of improper, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

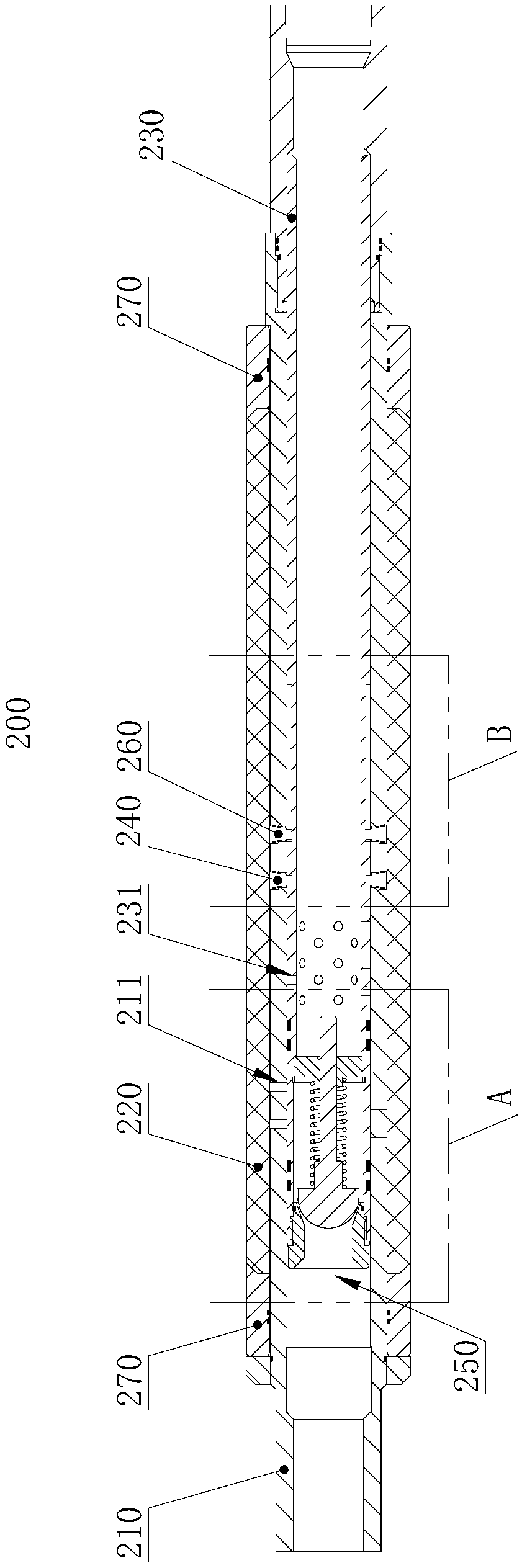

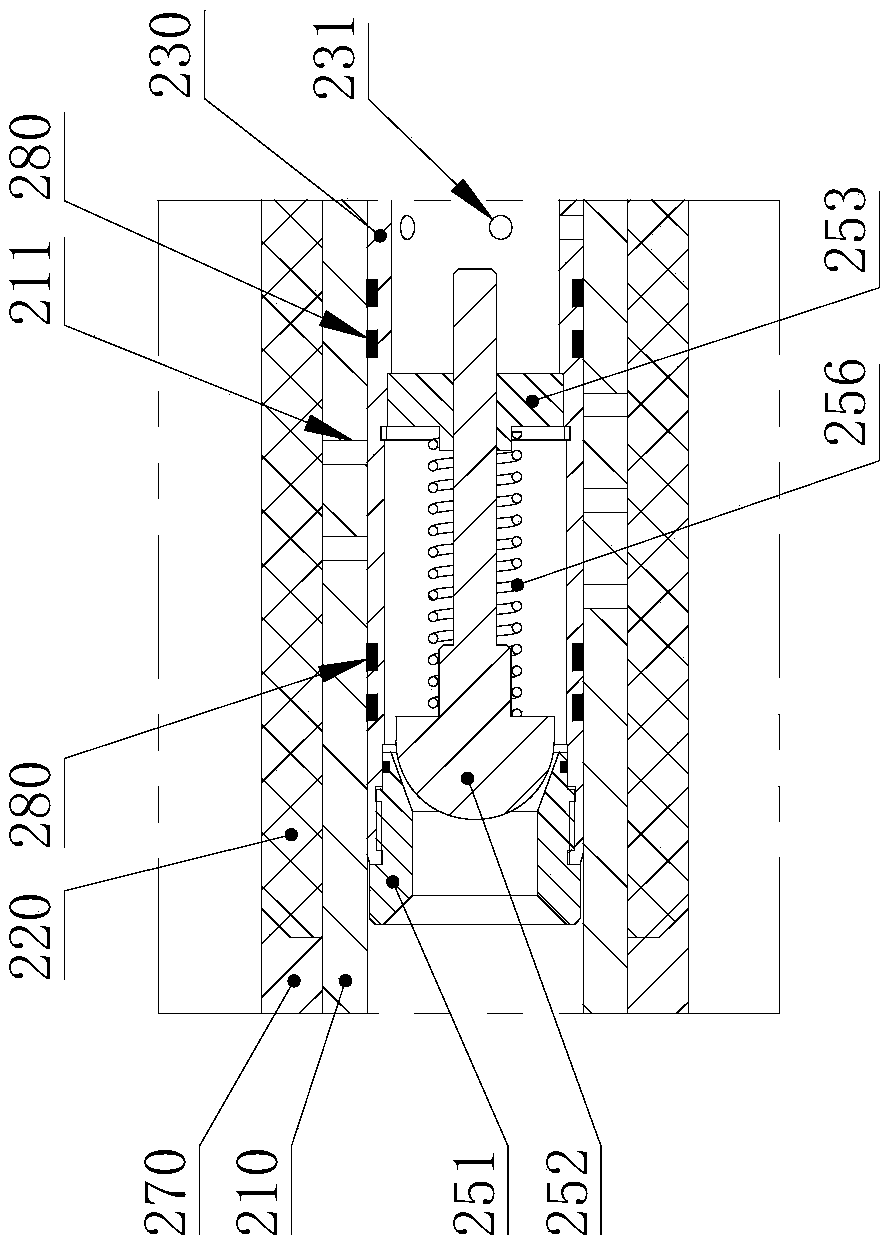

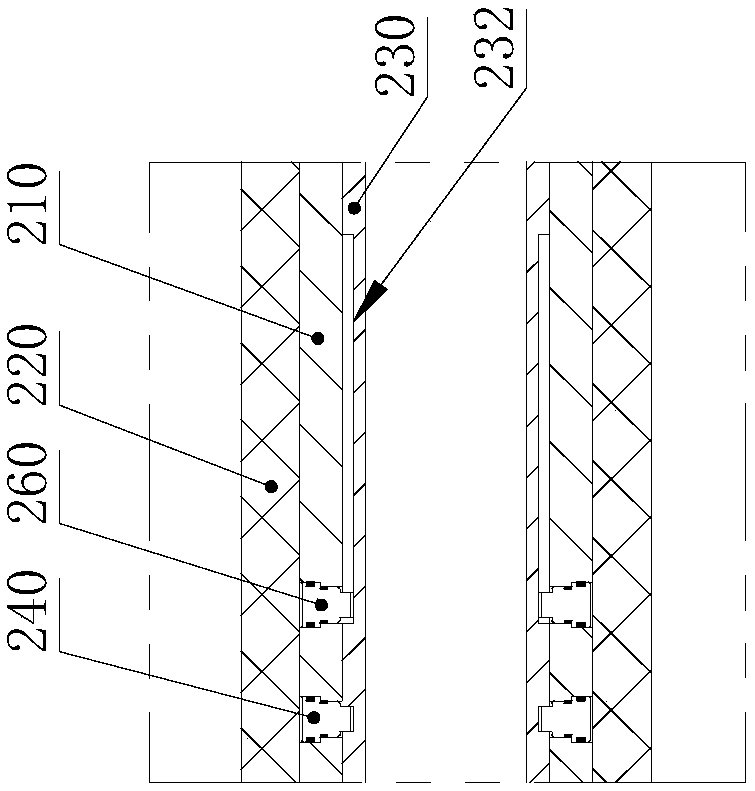

[0037] Please refer to figure 1 - image 3 , the BOP while drilling device 200 includes a connecting cylinder 210, one end of the connecting cylinder 210 communicates with the drilling fluid pipe, and the other end is threadedly connected with the drill pipe joint 290, which is used to connect the drill string, and the drill pipe joint 290 passes O-shaped The ring is in sealing fit with the connecting cylinder 210. The outer wall of the connecting barrel 210 is provided with a rubber barrel 220 , and the two ends of the glue barrel 220 are in sealing connection with the outer wall of the connecting barrel 210 . A sliding sleeve 230 is provided on the inner side wall of the connecting cylinder 210 , and the sliding sleeve 230 can be slidably matched with the inner side wall of the connecting cylinder 210 . The inner side wall of the sliding sleeve 230 is provided with a self-control valve 250 , which can be automatically opened or closed according to the pressure change, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com