An oil production wellhead sealing protection device

A technology of sealing protection and sealing seat, applied in the directions of sealing/isolation, earth-moving drilling, drilling equipment, etc., it can solve the problems of poor sealing effect of polished rod sealing device and easy dirtiness of polished rods, so as to avoid blowout accidents and avoid failures. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

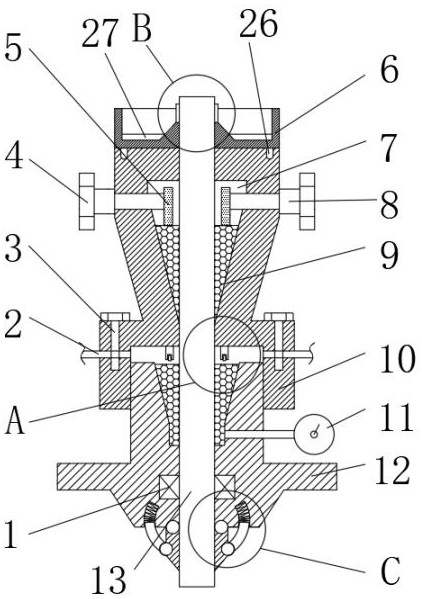

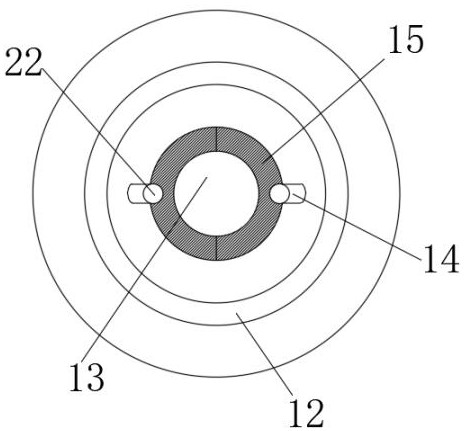

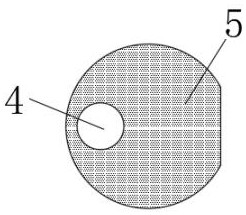

[0025] Such as Figure 1-6 As shown, the embodiment of the present invention provides a sealing and protection device for oil production wellhead, including a sealing seat 12, which realizes the first layer of sealing to the oil wellhead. The middle side of both sides is provided with a sliding chamber 24, the sliding chamber 24 is used for the hard spring 25 to push the arc rod 14, and the side wall of the middle part of the sealing seat 12 is provided with a pressure gauge 11, and the pressure gauge 11 is used for testing The pressure of the seal in the oil wellhead, the outer circumference of the upper end of the sealing seat 12 is threadedly connected with the connecting seat 10, the connecting seat 10 is used for the second sealing of the oil wellhead, the middle part of the connecting seat 10 runs through a polished rod 13 vertically, and the inner bottom of the connecting seat 10 A second sealing cavity 18 is formed between the sealing seat 12, and the inner bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com