Slurry gas detecting method in pit

A downhole detection and mud technology, applied in measurement, earthwork drilling, wellbore/well components, etc., can solve problems such as inability to accelerate electrocatalytic oxidation of methane, high current density, etc., to prevent blowout accidents, prevent reactions, and meet the requirements of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

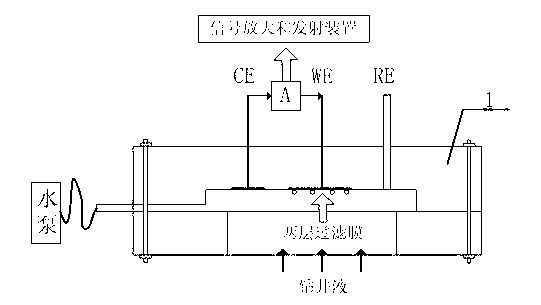

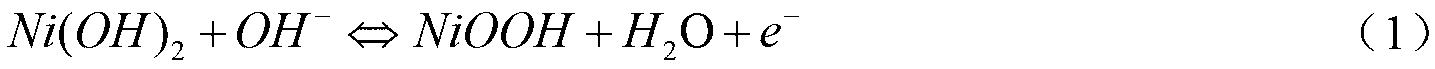

[0026] The main realization principles and specific implementation methods of the technical solutions of the present invention will be described in detail below with reference to the accompanying drawings. The method provided by the present invention adopts the principle of electrochemical method to detect mud gas downhole, and an electrochemical detection chamber is designed. The working principle of the device is as follows: figure 1 shown. It mainly includes: a water pump to ensure that the liquid in the electrochemical detection room keeps flowing; the electrochemical detection room (1) mainly consists of a two-layer filter membrane structure and a three-electrode electrochemical test system (working electrode WE, contrast electrode CE, reference electrode RE) for filtering gas and performing catalytic reactions; signal processing and transmitting devices for amplification and wireless transmission of electrical signals.

[0027] Please refer to figure 1, its working pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com