Oil well blowout control device

An oil well and lateral technology, applied in wellbore/well components, sealing/packaging, earth-moving drilling, etc., can solve the problems of unfavorable blowout, labor-intensive workers, delay in the timing of emergency blowout, etc., to avoid major economic losses and Personal injury, significant economic and social benefits, and the effect of preventing blowout accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

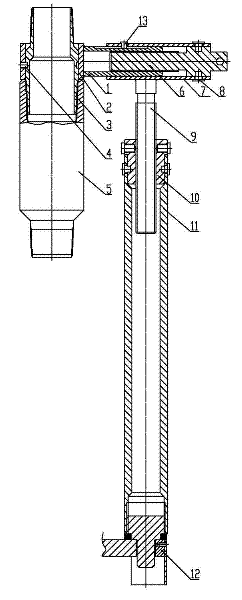

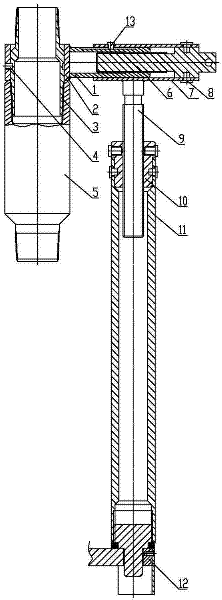

[0007] Combine below figure 1 Examples of the present invention will be described.

[0008] As can be seen from the figure, the embodiment of the present invention includes a transverse nut 1, a ferrule 2, a variable buckle joint 3, a limit pin 4, a transverse screw 6, a sleeve 7, an anti-tampering pin 8, a vertical screw 9, and a vertical nut 10 , adjusting pipe 11, fixed plate 12, anti-rotation pin 13, the lower part of the adjusting pipe 11 is installed on the fixed plate 12, and the fixed plate 12 is provided with two screw holes, and the two screw holes can overlap with the large cross of the wellhead, so it can be The fixing plate 12 is fixed on the large cross at the wellhead with bolts, so that the regulating pipe 11 is fixed near the wellhead. A vertical nut 10 is installed on the upper part of the adjustment pipe 11, and the vertical nut 10 is screwed with the vertical screw rod 9, and the vertical screw rod 9 is rotated so that the vertical screw rod 9 can walk up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com