Fracturing and sand prevention integrated process pipe column capable of preventing erosion and deeply backwashing well and operation method of fracturing and sand prevention integrated process pipe column

A technology for fracturing sand control and process strings, which is applied in the direction of flushing wellbore, drill pipe, casing, etc. It can solve the problems of inability to flush the string, reduce construction costs, and the safety valve is easy to be eroded, so as to reduce sand sticking risk, prevent blowout accidents, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below through specific embodiments.

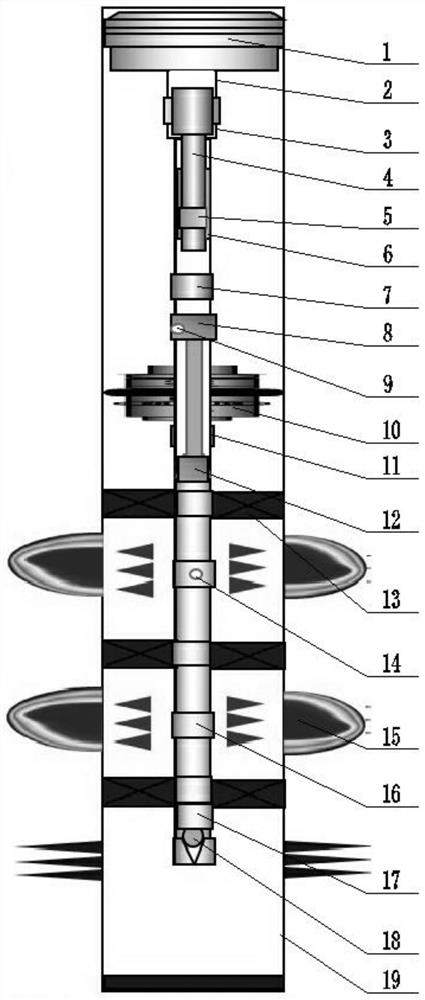

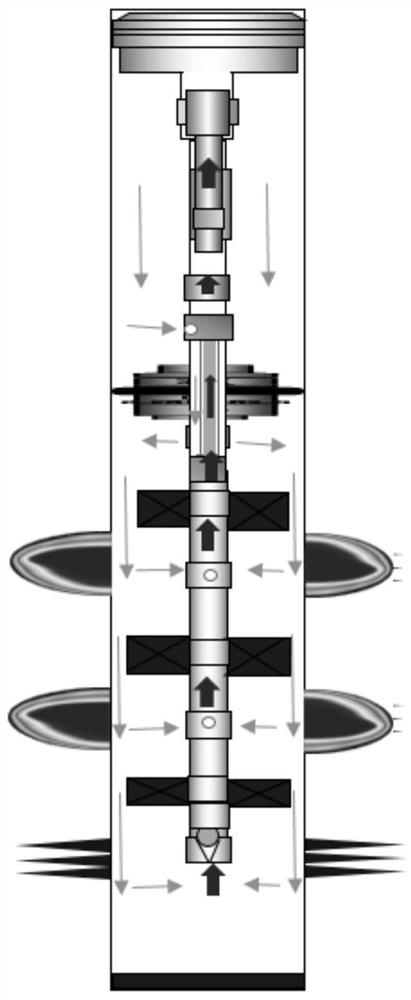

[0028] A fracturing and sand control integrated process string that can prevent erosion and deep backwashing wells, including well control part, anti-erosion part, deep backwashing well part and layered fracturing part, well control part includes safety with valve disc Valve 5, upper hydraulic anchor 7 and annular packer 10, the anti-erosion part includes an upper sealing cylinder 3, a hollow cannula 4 and a lower sealing cylinder 6, and the deep backflushing part includes a deep well flushing valve 8, a well flushing pressure The differential rupture disk 9, the well flushing water outlet 11 and the insert seal 12 in the tubing, the stratified fracturing part includes the Y344 packer 13, the ball-throwing sandblasting sliding sleeve 14, the normally open sandblasting sliding sleeve 16, the lower hydraulic anchor 17 and the single Flow valve ball seat 18;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com