Movable drill pipe lay-down machine for oil field drilling and workover

A technology of discharging machine and drill pipe, applied in drill pipe, drilling equipment, drill pipe, etc., can solve the problems of high labor intensity of operators, inability to ensure the concentricity of drill pipe, and difficulty in buckling of drill pipe, and achieve significant economic benefits and efficiency. Social benefits, convenient construction, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

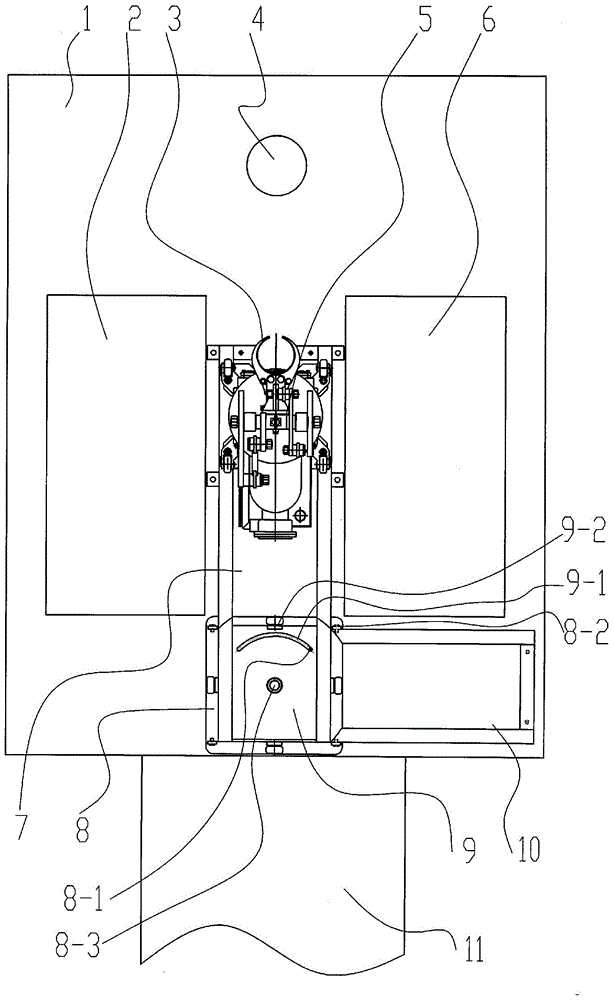

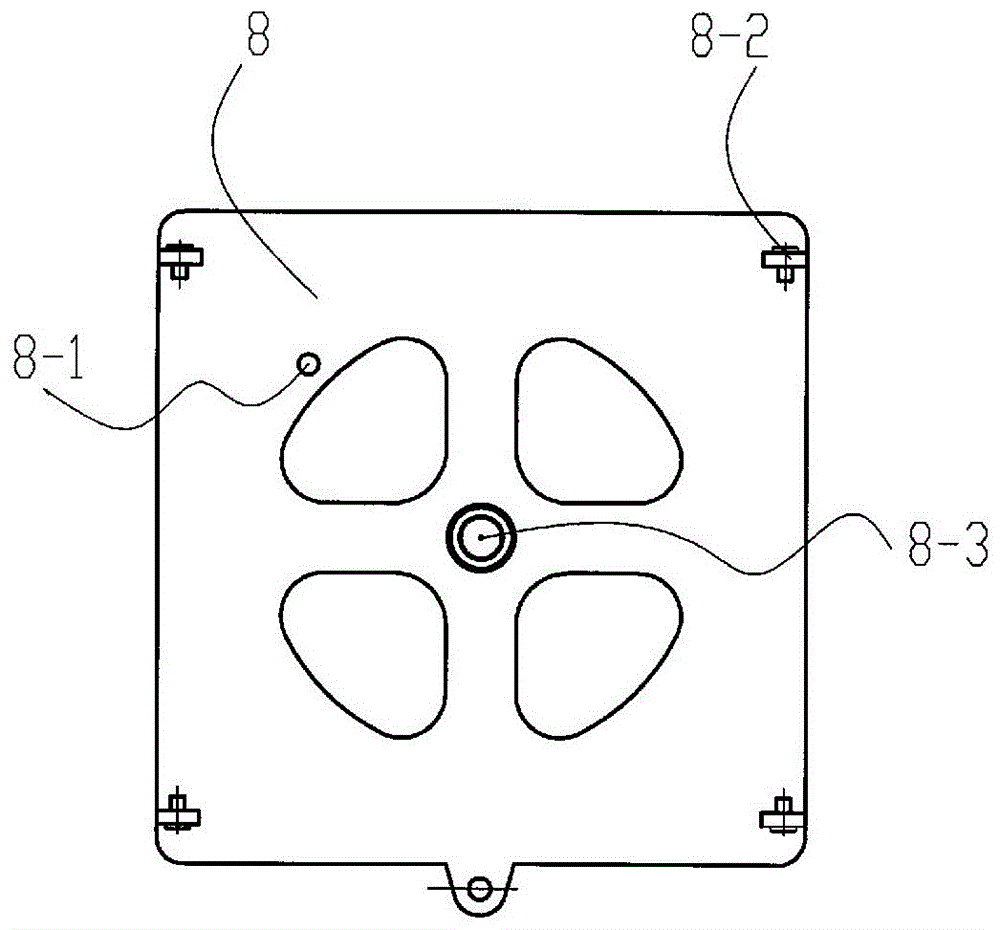

[0016] As can be seen from the figure, the embodiment of the present invention includes a drill repair platform 1, a left drill pipe vertical storage box 2, a gripper 3, a discharge machine 5, a right drill pipe vertical storage box 6, a track frame 7, a track seat 8, a rotating Frame 9, transfer track frame 10, ramp 11, there is borehole 4 on the drilling and repairing platform 1, and the wellbore 4 is in the front part of drilling and repairing platform 1, and the left vertical drill pipe box 2, the right Drill pipe vertically puts box 6, installs rail frame 7 at the aisle place between left drill pipe vertically put box 2, right drill pipe vertically put box 6, two vertical rails 7-1 of rail frame 7 are installed in parallel, in described The discharge machine 5 is installed on the vertical track 7-1, the discharge machine 5 can walk on the vertical track 7-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com