Preparing method of double-sided knitted carbon brake disc prefabricated body

A technology of carbon brake discs and prefabricated bodies, which is applied in the fields of acupuncture machines, chemical instruments and methods, textiles and papermaking, etc. It can solve the problems of carbon brake disc performance mismatch and low deposition efficiency of carbon brake discs, so as to prevent partial wear The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation plan

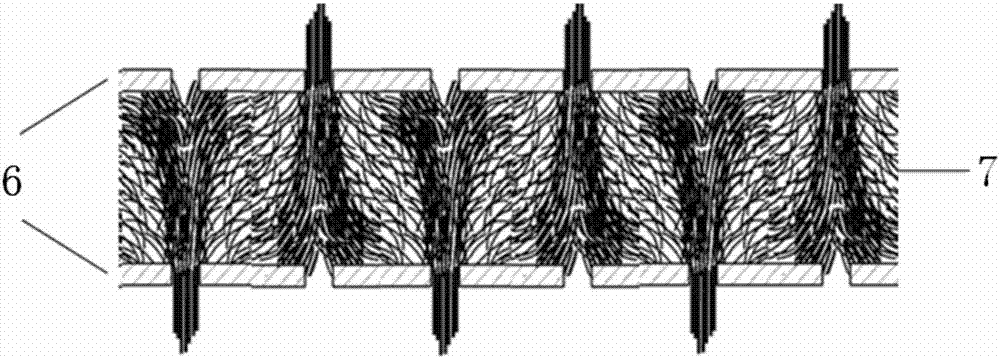

[0030] This example is the preparation of a double-sided composite needle-punched preform. The prefabricated body adopts HTS-12K PAN-based carbon fiber.

[0031] Step 1, manufacture mesh tire.

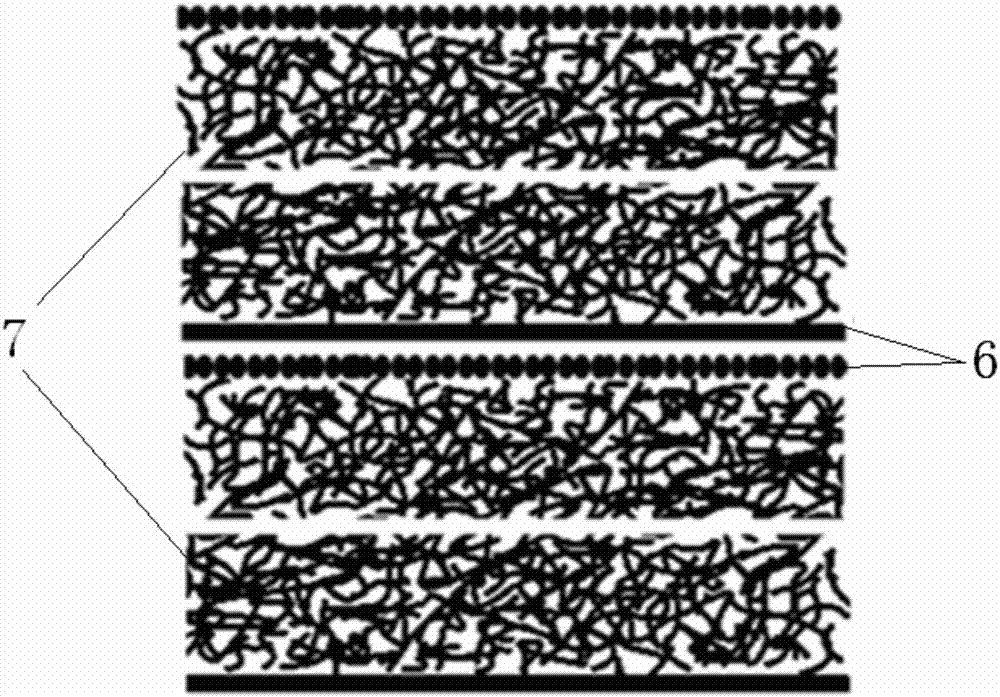

[0032] Utilize the net tire production line of prior art to manufacture net tire 7. The short carbon fiber filaments that have been cut are transported into the carding machine through the feed curtain, and are combed into a net through a cylinder and a carding rod to form a finished net tire 7 of 350mm×50m, which is rolled up for use.

[0033] Step 2, manufacturing unit layers.

[0034] Unfold the finished net tire obtained on the cutting workbench. The carbon fiber filaments are drawn out through the carbon fiber wire frame and laid on the mesh tire. Cutting the mesh tire laid with the carbon fiber filaments to obtain multiple unit layers of 350mm×350mm.

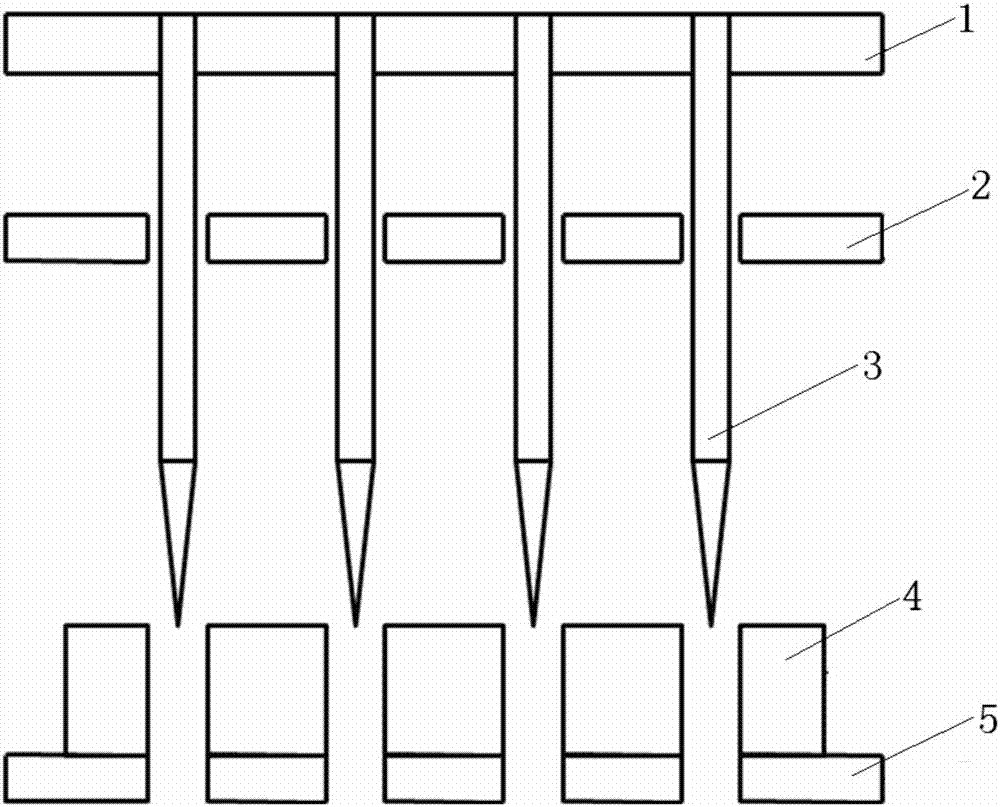

[0035] Step 3, setting acupuncture parameters.

[0036] Before needling, first set t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com