Inner pull rod design

An inner tie rod and tie rod technology, applied in the direction of piston rods, mechanical equipment, engine components, etc., can solve the problems of reduced service life of tie rods and pistons, failure to meet normal use requirements, and failure of cylinders to work normally, so as to avoid eccentric wear. , Improve service life and unreliability, reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

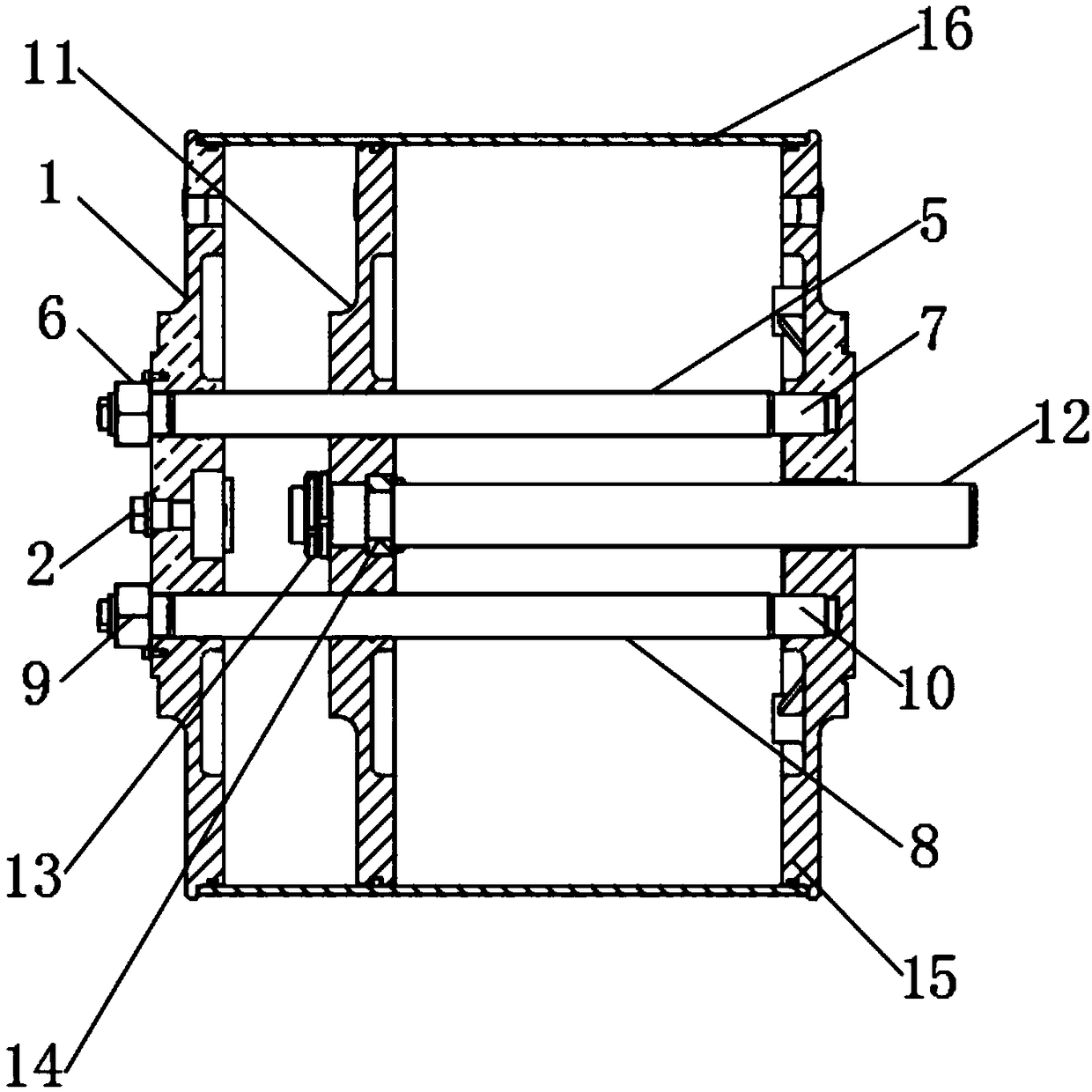

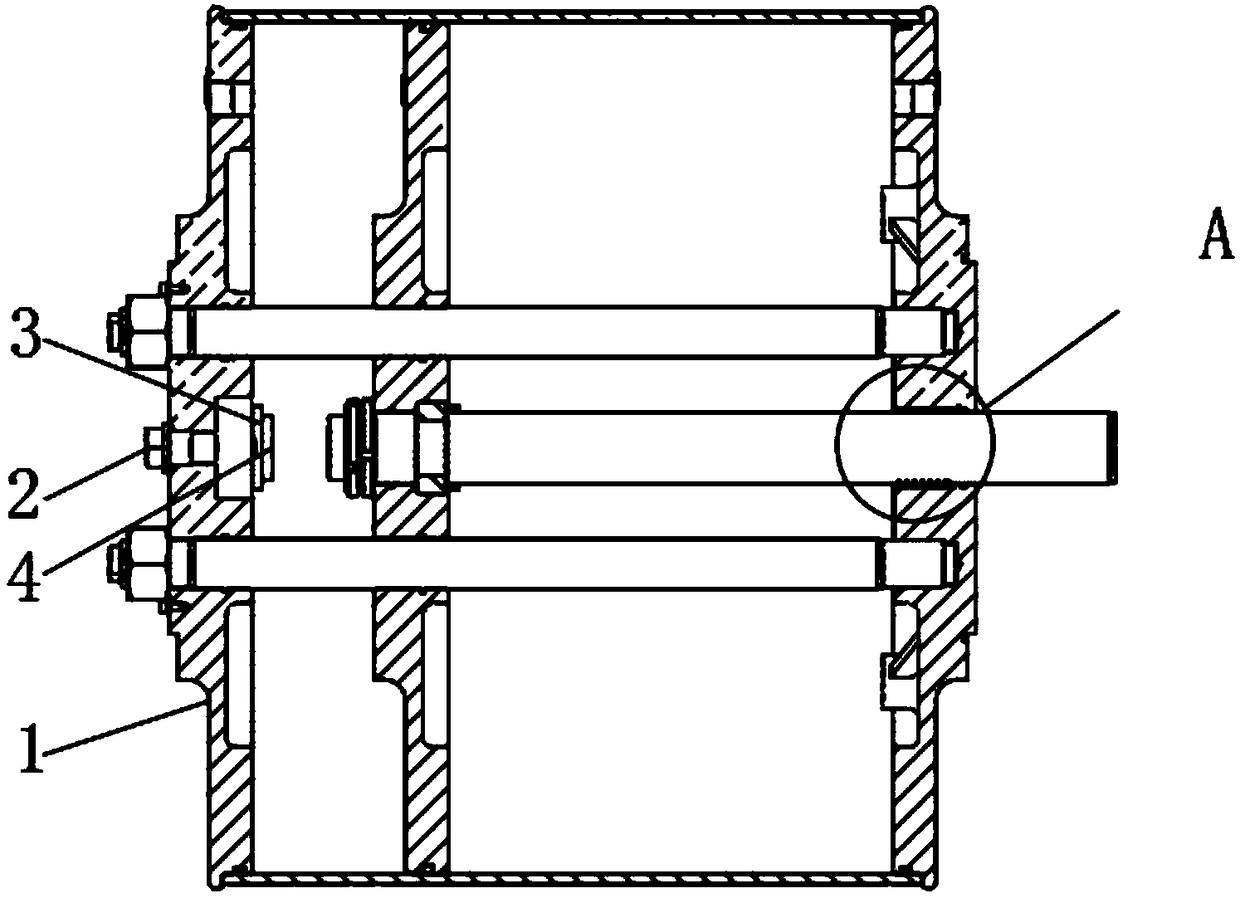

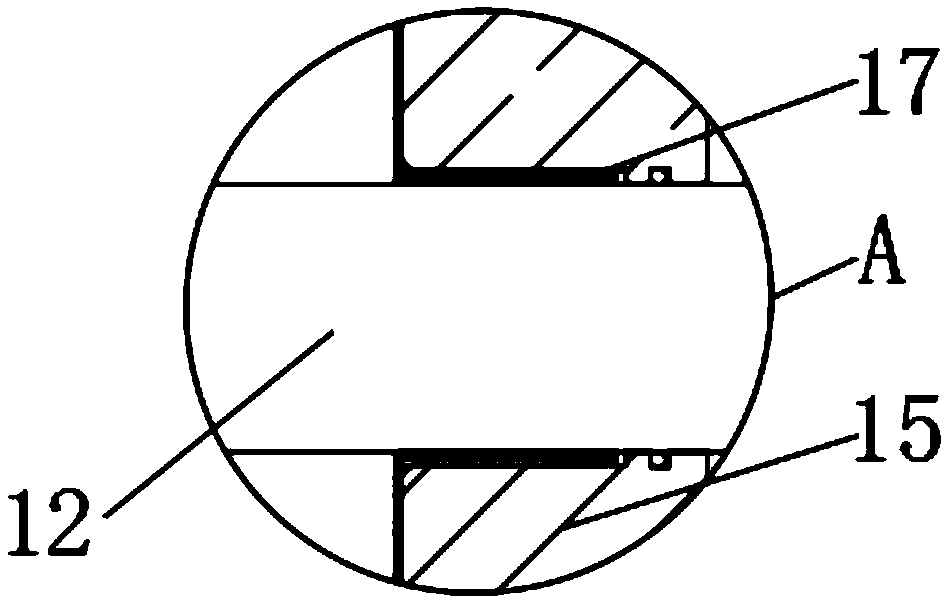

[0019] Such as Figure 1-3 As shown, a design of an inner tie rod includes a No. 1 cylinder head 1 and a No. 2 cylinder head 15. A fastening bolt 2 is movably installed on the inner surface of one end of the No. 1 cylinder head 1 near the middle, and the other side of the fastening bolt 2 A fixing seat 3 is fixedly installed on the outer surface of one end, and a cushion block 4 is provided on one side of the outer surface of the fixing seat 3, and a No. 1 pull rod 5 is provided on the inner surface of one end of the No. 1 cylinder head 1 above the fastening bolt 2. No. 1 nut 6 is movably installed on the outer surface of No. 1 pull rod 5, and No. 1 connector 7 is fixedly installed on the outer surface of one end of No. 1 pull rod 5. There is No. 2 tie rod 8, No. 2 nut 9 is movably installed on the outer surface of No. 2 tie rod 8, and No. 2 connector 10 is fixedly installed on the outer surface of one end of No. 2 tie rod 8. One side of No. 1 cylinder head 1 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com