Wire saw twisting machine and method for preventing eccentric grinding of diamond wire saw by using the wire saw twisting machine

A technology for a diamond wire saw and a wire saw machine is applied to the wire saw torsion machine and the use of the wire saw torsion machine to prevent the eccentric grinding of the diamond wire saw. and other problems, to achieve the effect of reducing the labor intensity of processing, high degree of automation, and increasing the rotation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

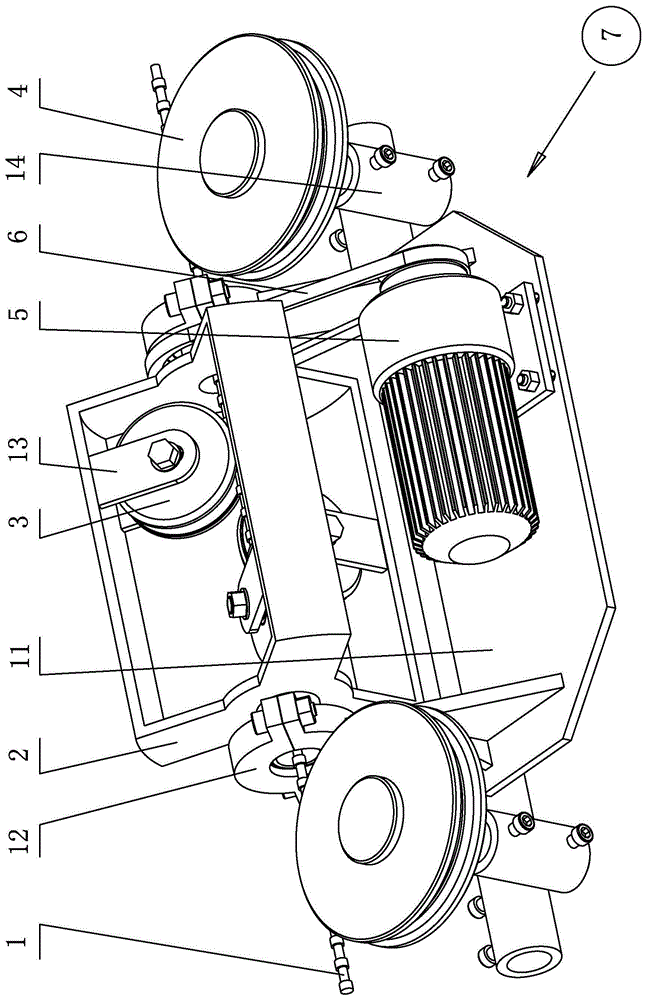

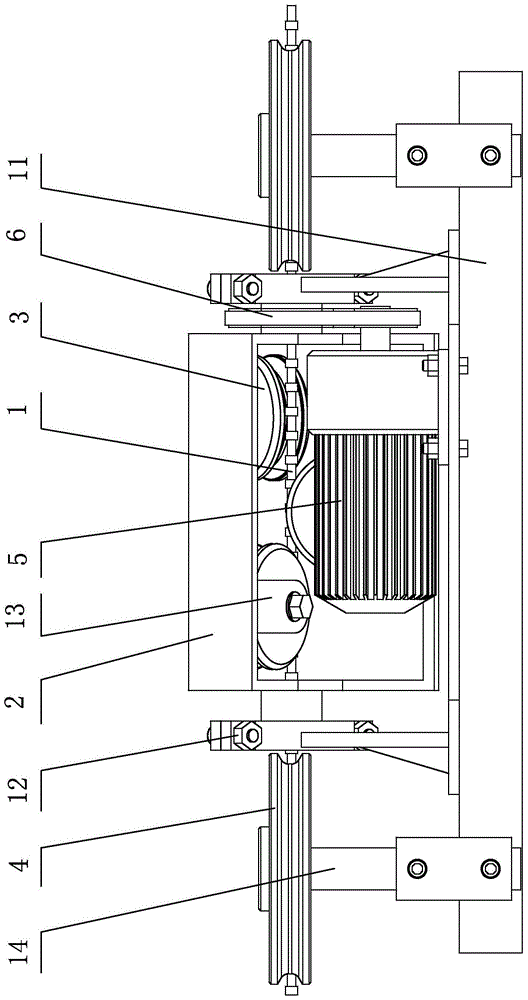

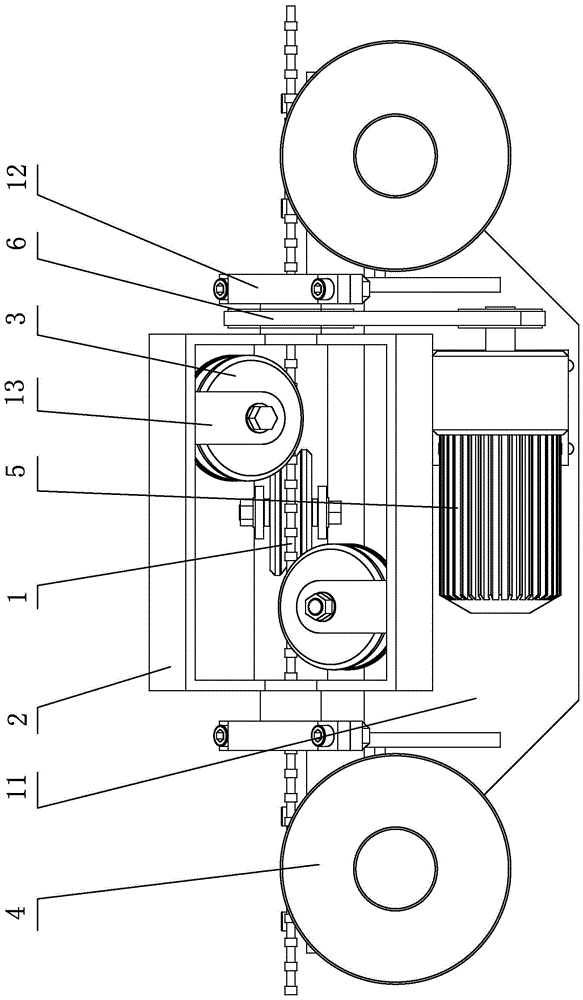

[0032] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0033] The wire saw twisting machine 7 of the present invention includes a rotating frame 2 based on a frame 11 , a twisting roller 3 , a guide wheel 4 , a twisting motor 5 and a pulley transmission pair 6 .

[0034] The rotating frame 2 is installed on the frame 11 between the front and rear bearing supports 12 through the front and rear hollow shafts. The radially adjustable torsion wheel frame 13 is respectively installed on each U-shaped frame body, and the three torsion rollers 3 are arranged on the side of the rotation axis of the rotation frame 2 forward, middle and rear along the axis, and the torsion rollers 3 are twisted in pairs. The included angles between the center planes of the wheels are 120°, and the center planes of the wheels of each torsion roller 3 are in the same plane as the axis of rotation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com