Tubular casting cooling and grinding device

A casting and tubular technology, which is applied in the field of tubular casting cooling and grinding devices, can solve the problems of low grinding efficiency and low efficiency, and achieve the effect of enhancing the grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

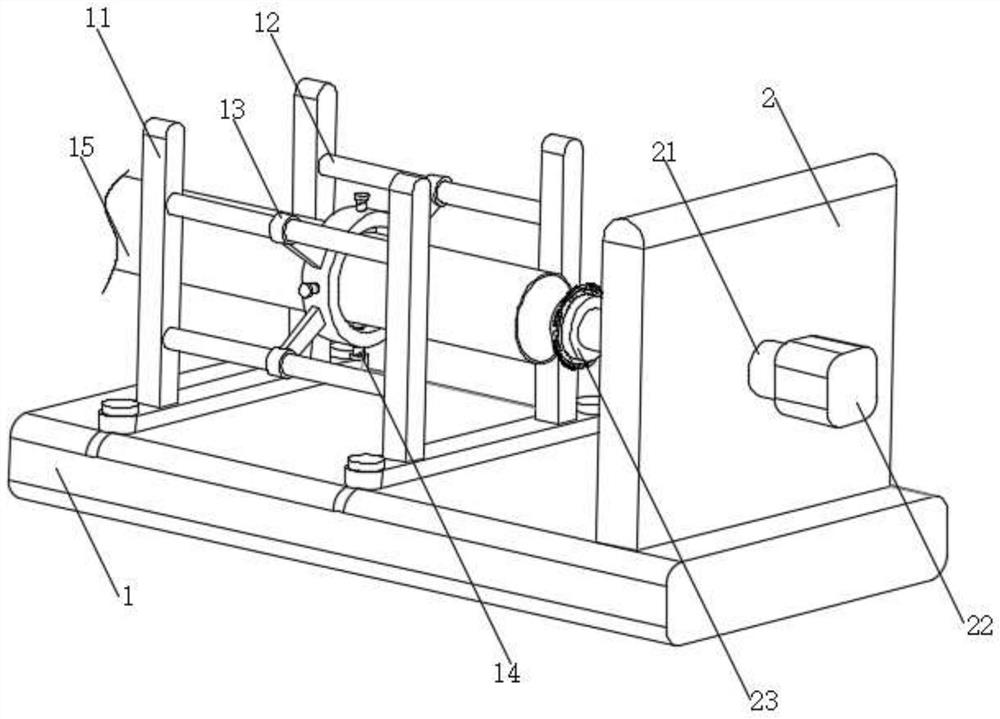

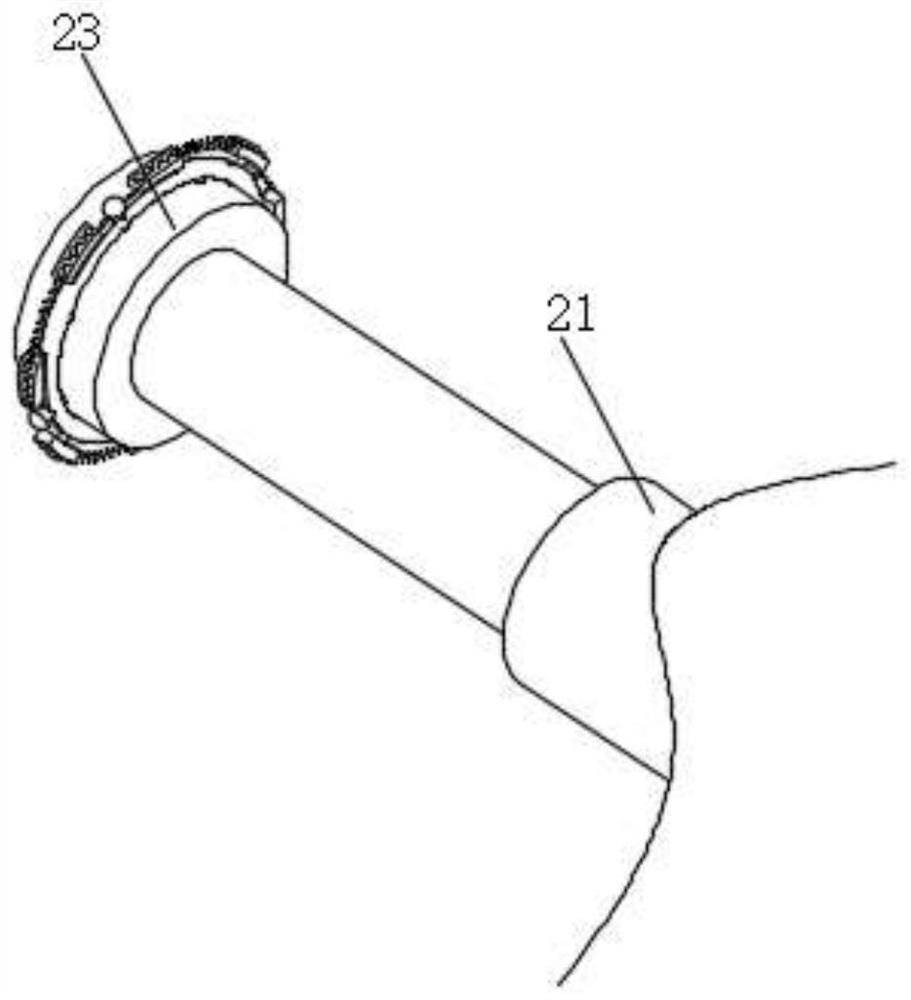

[0027] see Figure 1-Figure 3 As shown, the present invention is a tubular casting cooling and grinding device, including a base 1. The purpose of this setting is to facilitate the support of the entire device. Two support brackets 11 are provided on the left side of the top of the base 1. The purpose of this setting is to In order to facilitate the auxiliary setting of the crossbar 12, the upper and lower sides between the two support frames 11 are respectively fixedly connected with the crossbar 12. The purpose of this setting is to facilitate the auxiliary setting of the clamping ring 13, and the transverse rod 12 is provided with a clamping ring 13. The purpose of this setting is to facilitate the clamping of the pipe body 15, and a number of clamping bolts 14 are provided on the clamping ring 13. The purpose of this setting is to facilitate the fixing of the pipe body 15. Several clamping bolts 14 are threaded. Passing through the outer wall of the clamping ring 13, the p...

Embodiment 2

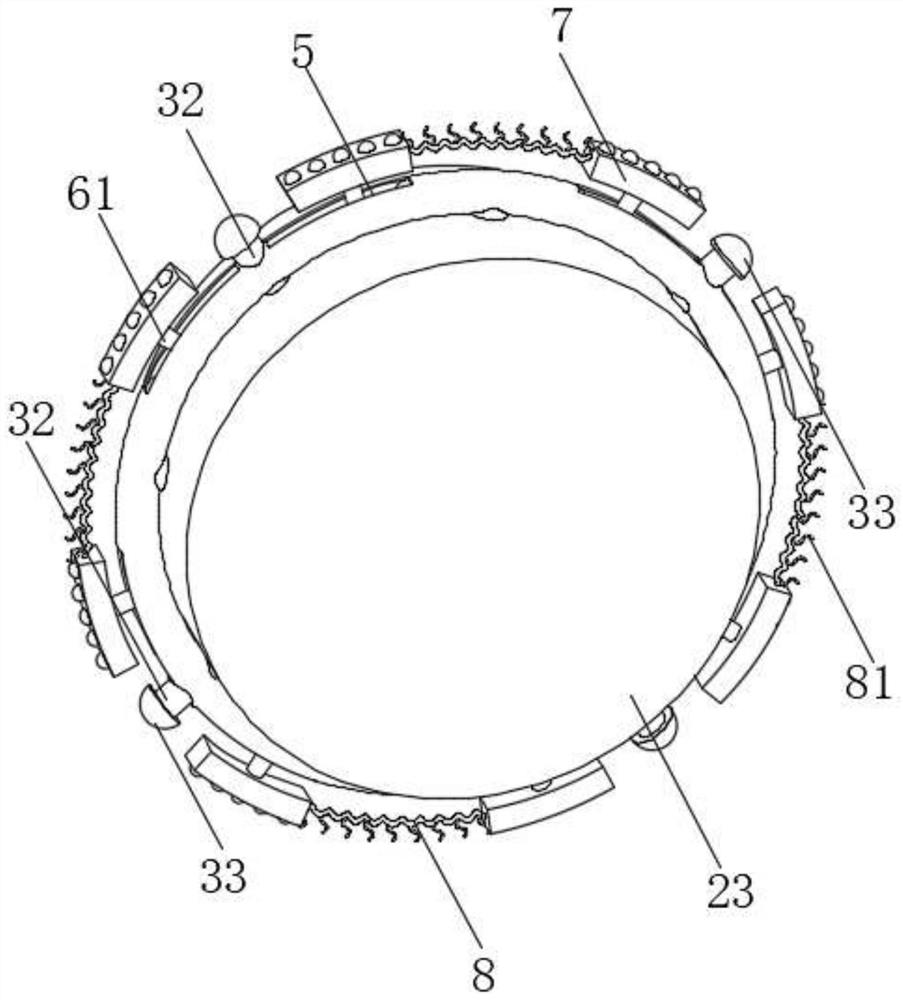

[0035] see Figure 1-Figure 6 As shown, the present invention is a tubular casting cooling and grinding device, including a base 1. The purpose of this setting is to facilitate the support of the entire device. Two support brackets 11 are provided on the left side of the top of the base 1. The purpose of this setting is to In order to facilitate the auxiliary setting of the crossbar 12, the upper and lower sides between the two support frames 11 are respectively fixedly connected with the crossbar 12. The purpose of this setting is to facilitate the auxiliary setting of the clamping ring 13, and the transverse rod 12 is provided with a clamping ring 13. The purpose of this setting is to facilitate the clamping of the pipe body 15, and a number of clamping bolts 14 are provided on the clamping ring 13. The purpose of this setting is to facilitate the fixing of the pipe body 15. Several clamping bolts 14 are threaded. Passing through the outer wall of the clamping ring 13, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com