Assembling and machining method of double-side universal conveying ball

A universal conveying ball, assembly and processing technology, applied in the field of conveying and transmission, to achieve the effects of reducing frictional resistance, improving conveying efficiency, and improving rotational lubrication performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

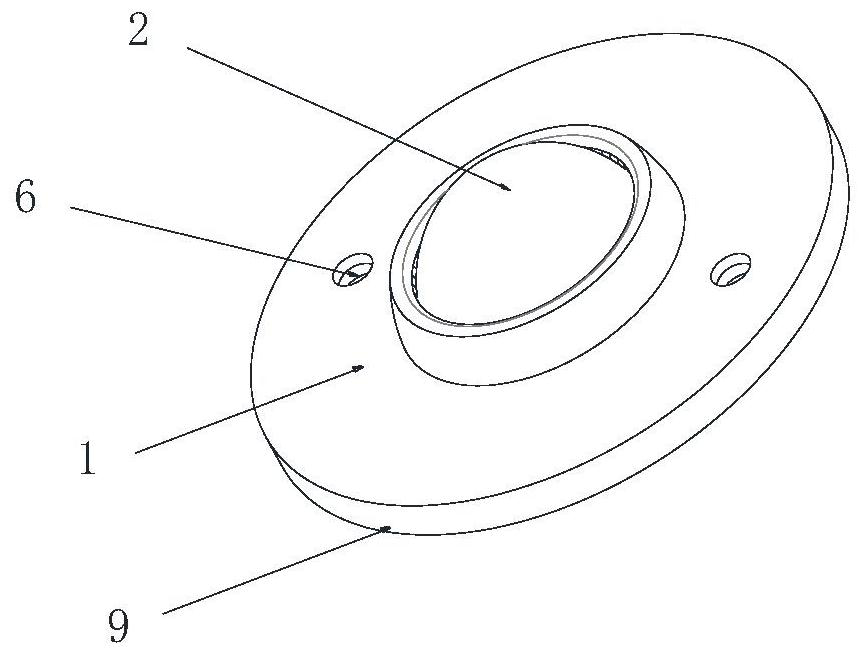

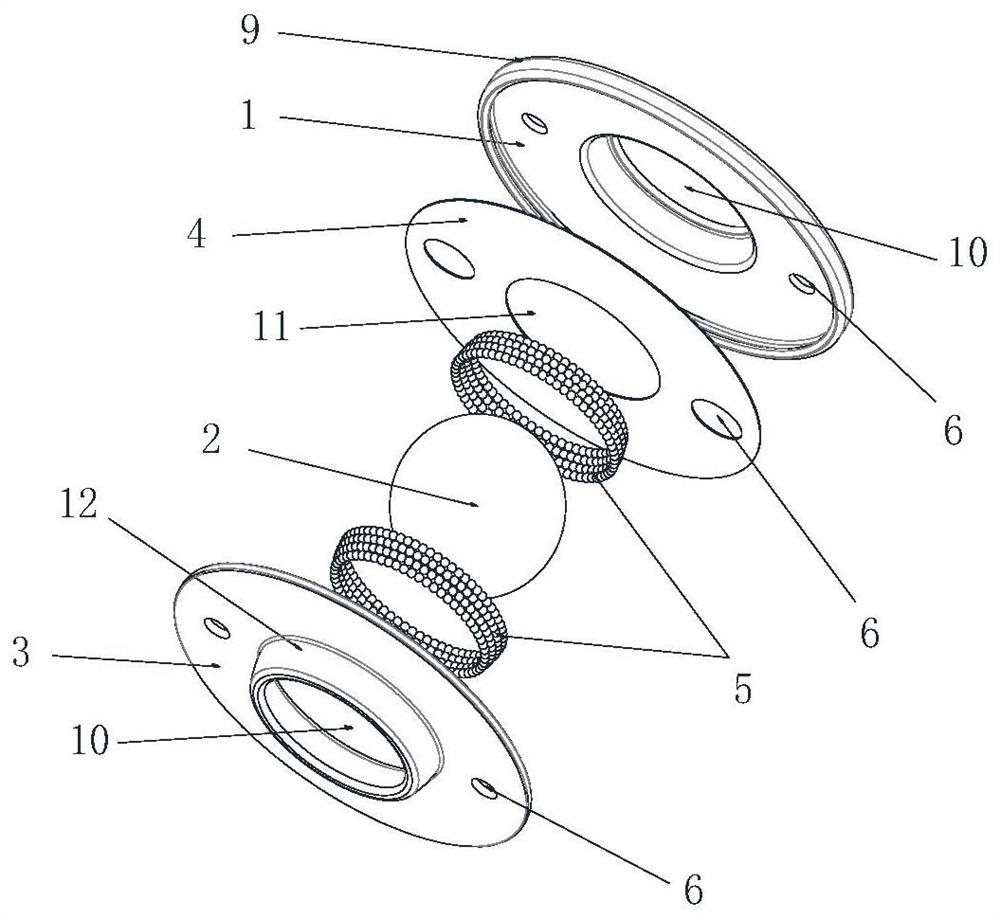

[0032] Example 1, such as figure 1 and figure 2 As shown, the double-sided universal conveying ball using the assembly and processing method described in this application includes an upper platen 1 and a lower bracket 3 that are connected to each other by clamps. Shaped through hole 10, the ball 2 is limited between the upper platen 1 and the lower bracket 3.

[0033] Specifically, a part of the ball 2 passes through the through holes 10 on the upper platen 1 and the lower bracket 3 to both sides, so that the ball 2 forms an arc-shaped contact surface on both sides that can be contacted and used for transportation and transmission. .

[0034] Further, a spacer plate 4 is lined between the upper platen 1 and the lower bracket 3, and the center of the spacer plate 4 is provided with a spacer plate through hole 11 that allows the ball 2 to pass through;

[0035] At the center of the upper platen 1 and the lower bracket 3, an outwardly protruding, annular protruding ring 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com