Ground driving motor of teetch-difference deceleration screw pump

A technology for driving motors and screw pumps, applied in gear transmissions, electrical components, electromechanical devices, etc., can solve the problems of small cost reduction, increased maintenance costs, environmental pollution, etc., to reduce the probability of seal failure, improve The effect of work safety and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

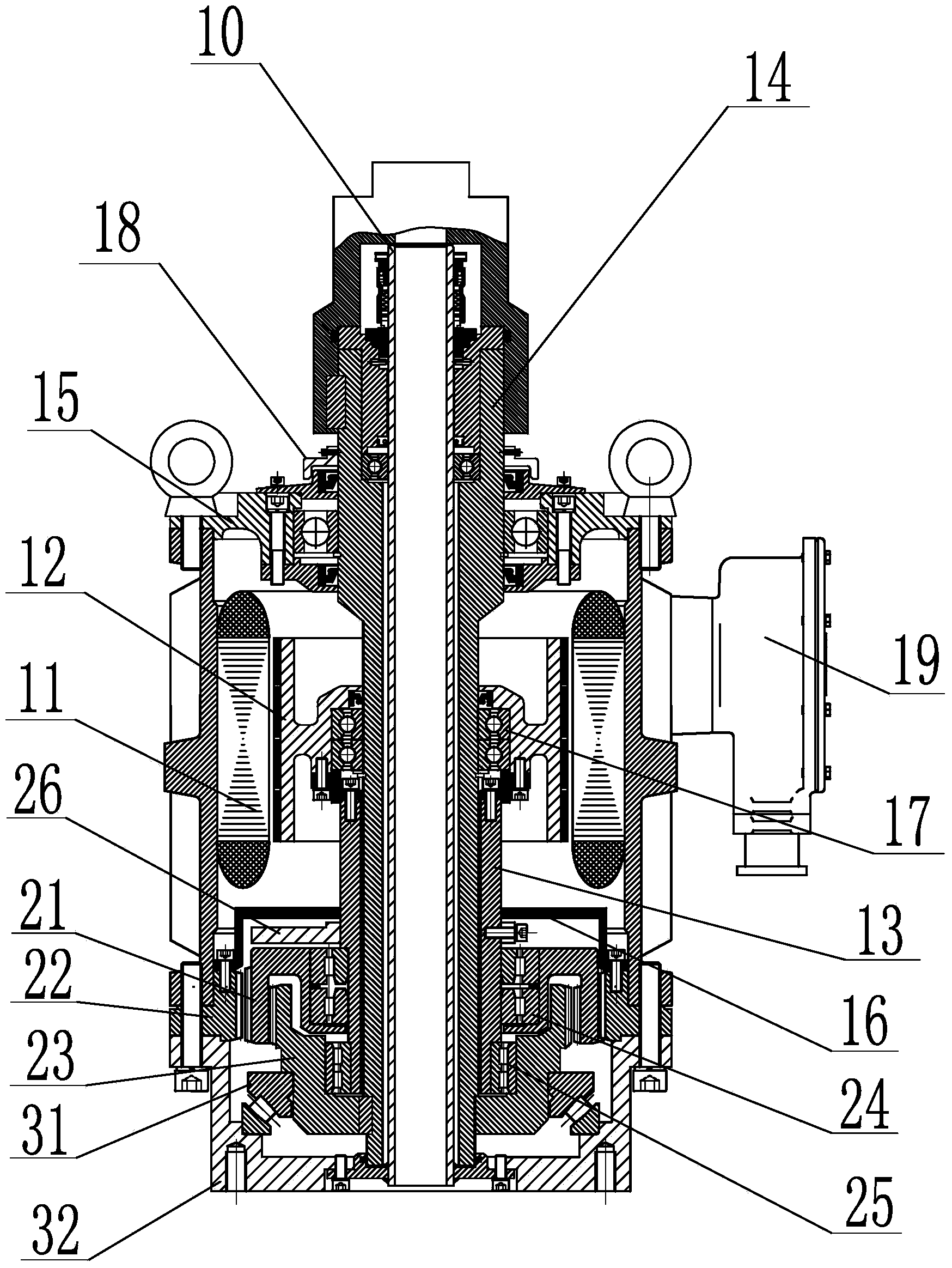

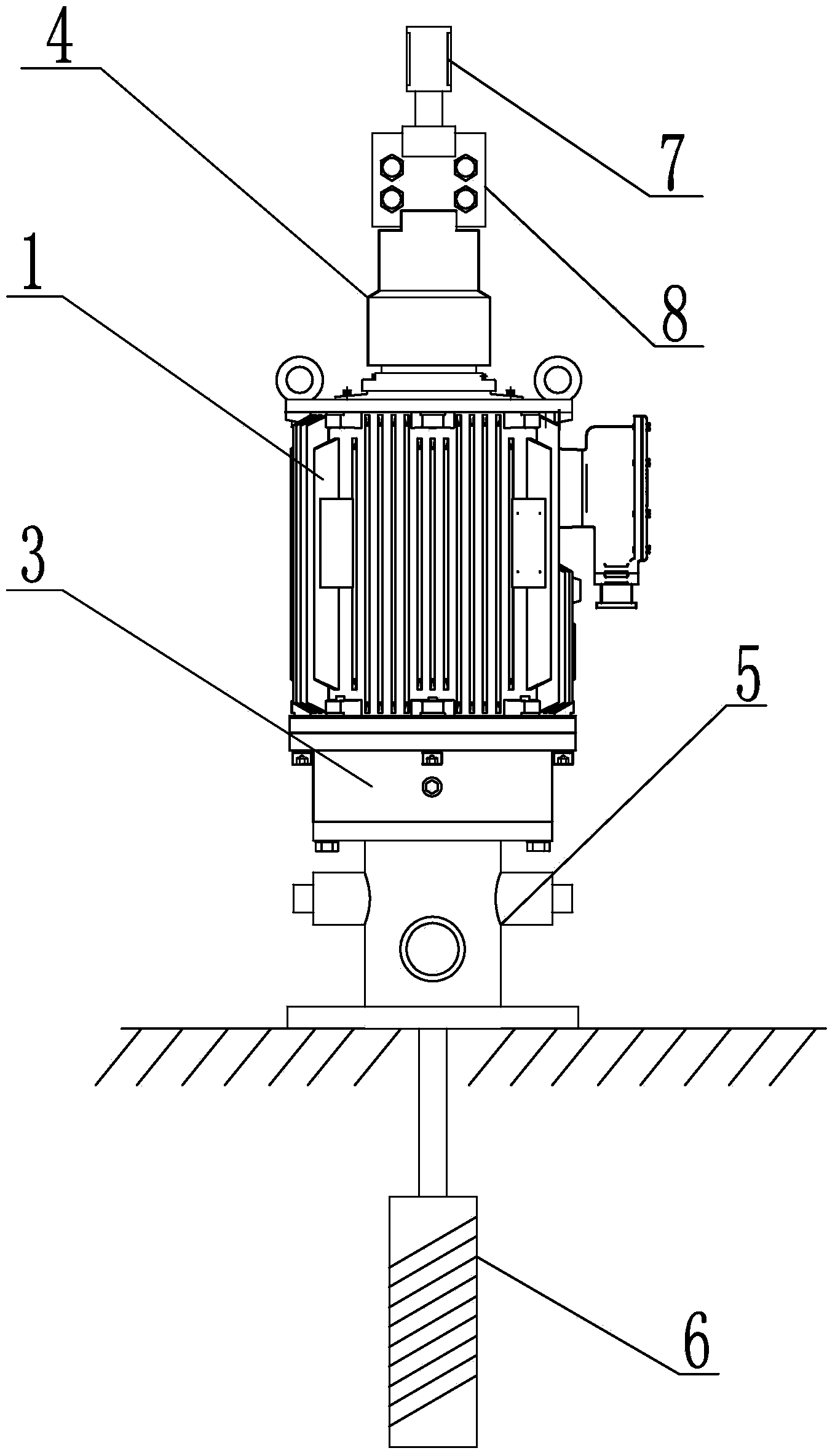

[0015] Such as figure 1 , figure 2 The shown ground driving motor of a differential gear reduction screw pump includes a motor drive part 1 arranged at the upper end and a bearing support assembly 3 arranged at the lower end. The drive part 1 includes a stator 11, a rotor 12, a main shaft 14, an eccentric Shaft 13 and rotor bearing 17, the driving part 1 is installed inside the casing, a junction box 19 is arranged outside the casing, and an upper end cover 15 is fixed on the upper end of the casing by bolts, the main shaft 12 runs through the upper end cover 15, and the main shaft 12 The part where the upper end cover 15 is exposed is equipped with an outer shaft 4, and a rotating sealing cover 18 is also provided between the outer shaft 4 and the upper end cover 15. The outer ring of the rotor bearing 17 is matched with the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com