Milling wheel with cutting teeth and for double-wheel slot milling machine

A double-wheel milling and pick technology, which is used in earthmovers/shovels, construction, etc., can solve the problems of increasing the angle of left and right deflection of picks, reducing the service life of picks, and increasing the resistance of pick milling. Achieve the effect of avoiding eccentric wear, uniform wear and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

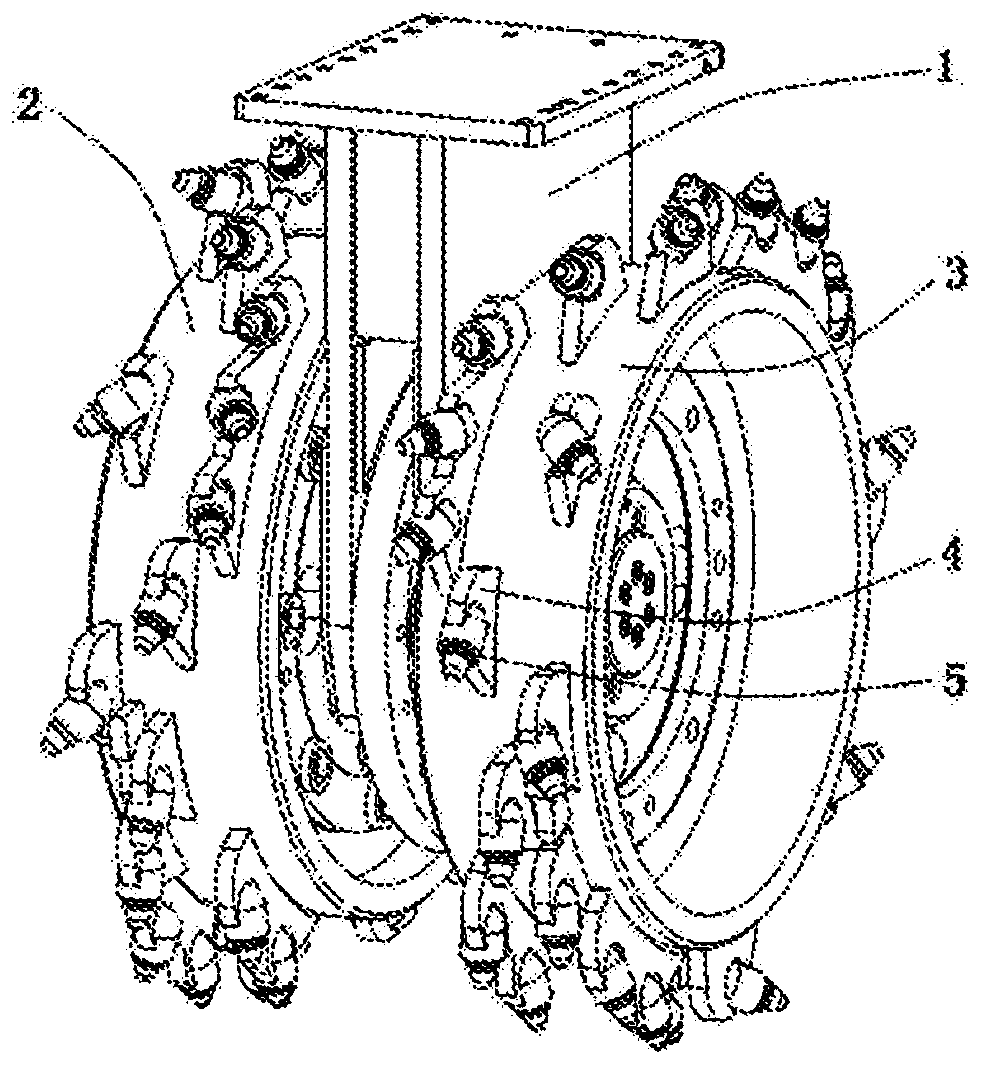

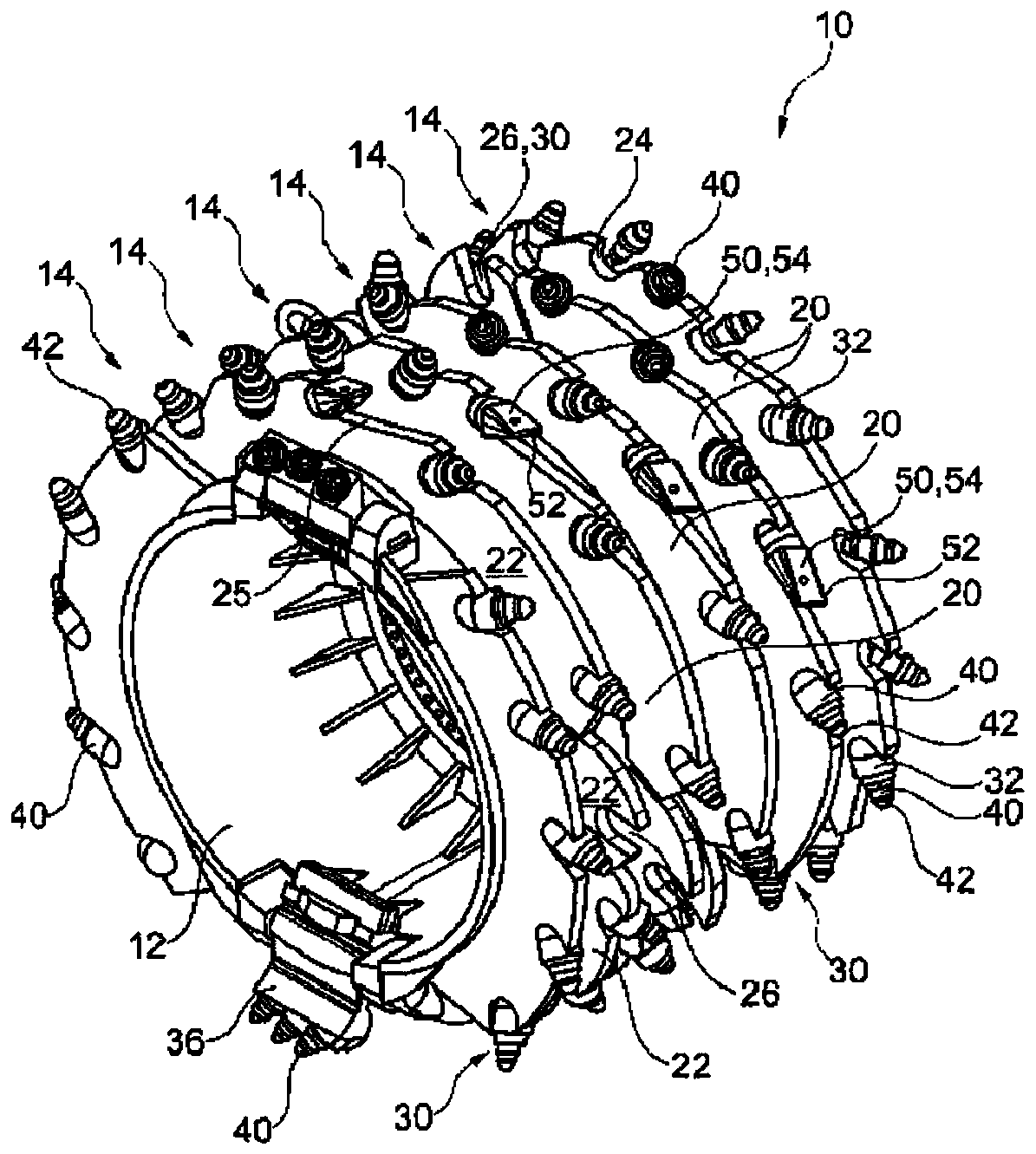

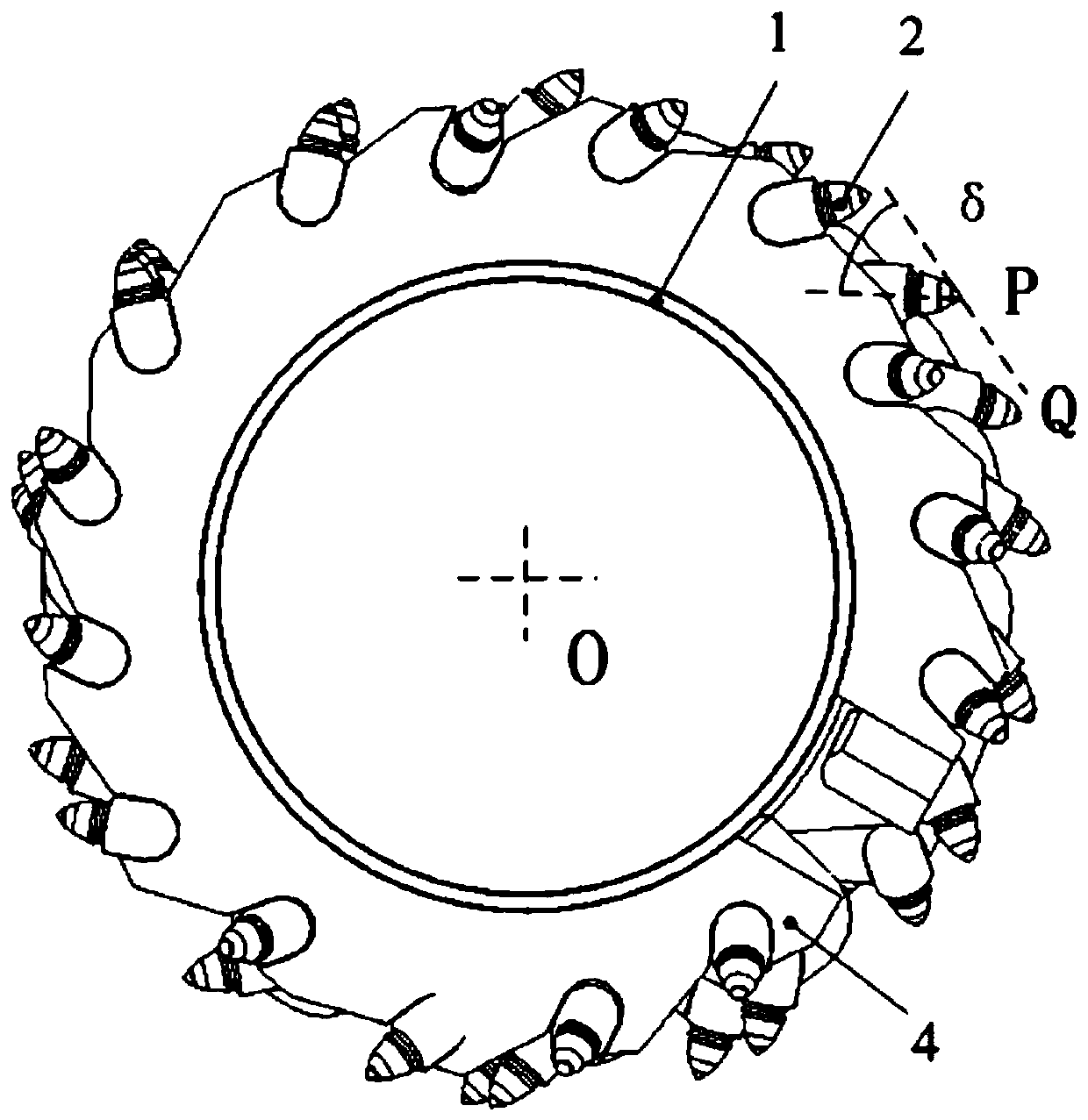

[0033] Such as image 3 and Figure 4 As shown, the double-wheel milling wheel provided by the present invention includes: a hub 1 , a pick 2 , a tooth seat 3 and a support plate 4 . The support plate 4 is fixed on the hub 1 by welding, the tooth seat 3 is welded in the mounting hole of the support plate 4 with certain positioning parameters, the tooth seat 3 and the pick 2 are assembled together, and the pick 2 can rotate in the tooth seat 3 .

[0034] Terms mentioned in this protocol are explained as follows:

[0035] Set milling wheel rotation center O, radial X, axial Y.

[0036] The envelope of the milling wheel: the relationship curve between the milling radius of the milling wheel pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com