Electromagnetic brake

An electromagnetic brake and brake plate technology, applied in the direction of the hoisting device, etc., can solve the problems such as the inability to unilaterally adjust the contact between the brake pad and the rotor, the automatic adjustment of the friction angle, and the asymmetric wear of the brake pad, so as to achieve a novel appearance and improve production. Efficiency and easy air gap adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

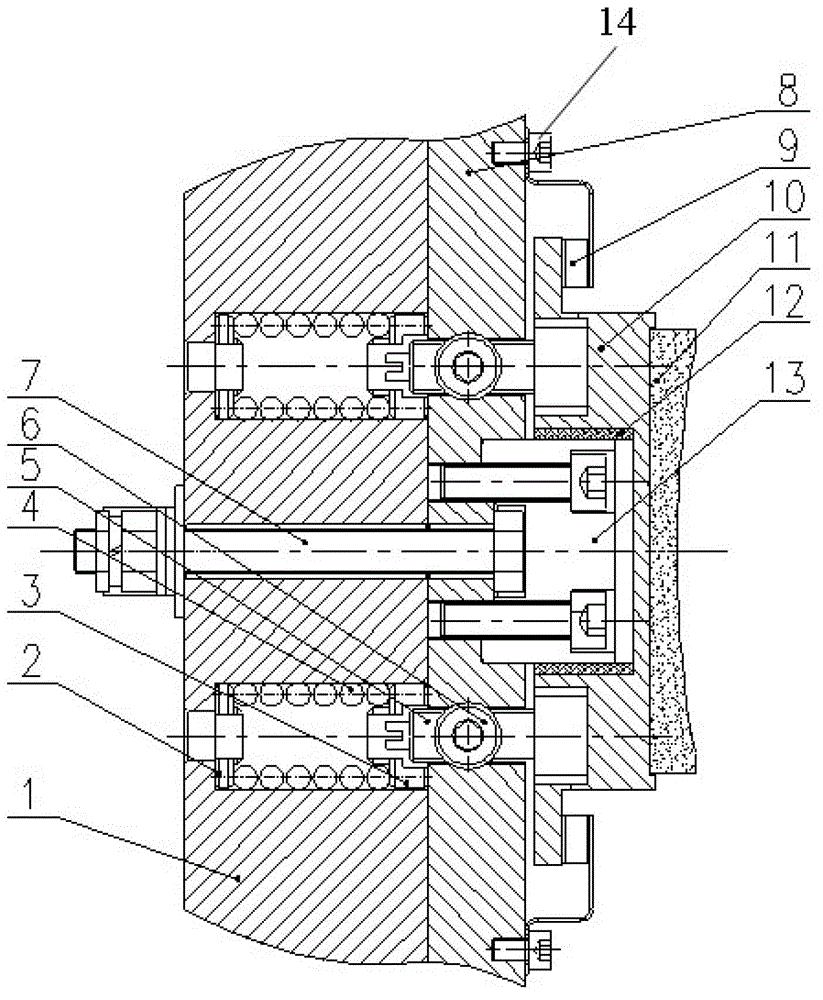

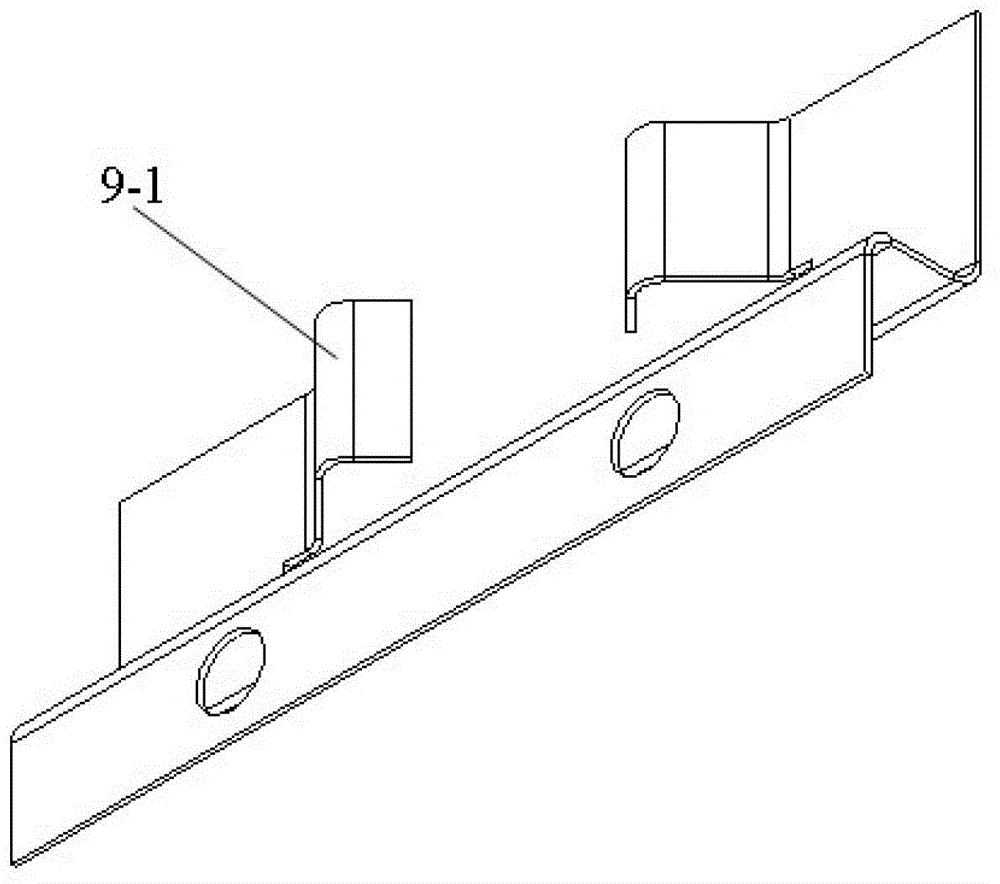

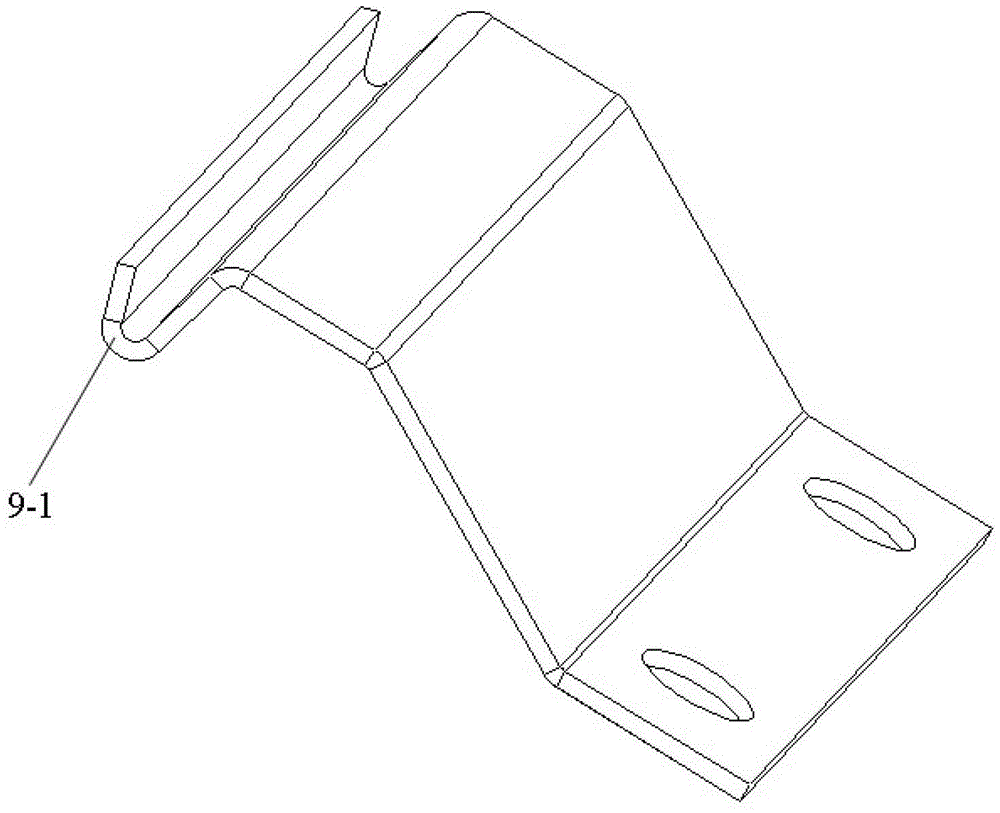

[0023] The accompanying drawings can represent the best embodiments of the present invention, and the detailed technical contents and embodiments of the present invention will be further described below in conjunction with the accompanying drawings. However, it should be noted that the symbols and embodiments shown in the drawings should not be regarded as limitations on the technology of the present invention, and any modification and addition on the basis of the present invention should be regarded as the scope of protection of the present invention.

[0024] see Figure 1-3 , The electromagnetic brake in this embodiment includes an electromagnet 1, an armature 8, a brake plate 10, and a brake pad 11. The brake electromagnet 1 and the armature 8 are connected by a central bolt 7, which is an outer hexagon half-threaded bolt. Under normal conditions, that is, when the brake is energized, the electromagnet 1 is attracted to the armature 8; when the brake is powered off and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com