Electronic warp feeding system of warp knitting machine

An electronic warp let-off and warp knitting machine technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problem of difficulty in real-time control of warp let-off, not suitable for high speed, high precision, and inability to adapt to high product quality, etc. problem, to achieve the effect of convenient and intuitive operation interface, intuitive and clear alarm content, and good high-speed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

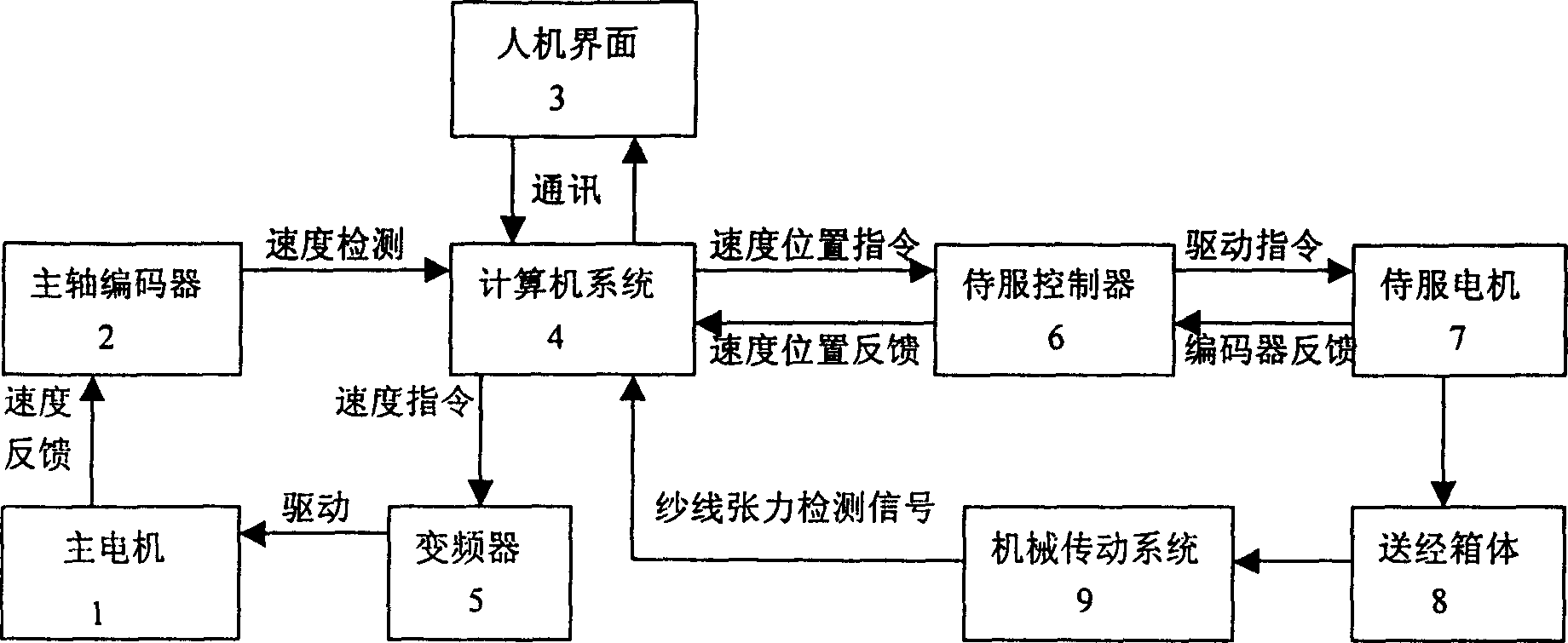

[0025] As shown in Figure 1, the present invention consists of a main motor 1, a spindle encoder 2, a computer system 4, a frequency converter 5, a servo controller 6, a servo motor 7, a let-off box 8 and a mechanical transmission system 9. The output shaft of the motor 1 is connected with the rotating shaft of the main shaft encoder 2 through a belt, which drives the main shaft encoder 2 to rotate and output the encoding signal, and the main shaft encoder 2 outputs the rotational speed encoding signal of the main motor 1 to the computer system 4 (using a common PC After that, through the calculation and processing of the specially compiled control software, the various process parameters of weaving input to the man-machine interface 3 (touch operation screen), such as the let-off amount, rotating speed, circumference, density, etc., and the computer system 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com