Constant speed variable pitch straight wing all direction propeller

A thruster and speed-changing technology, which is applied in the direction of rotary propellers, mechanical gear transmissions, etc., can solve the problems of multiple equipment, loose equipment arrangement, and low propulsion efficiency, and achieve high thrust, high efficiency, and excellent high-speed performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

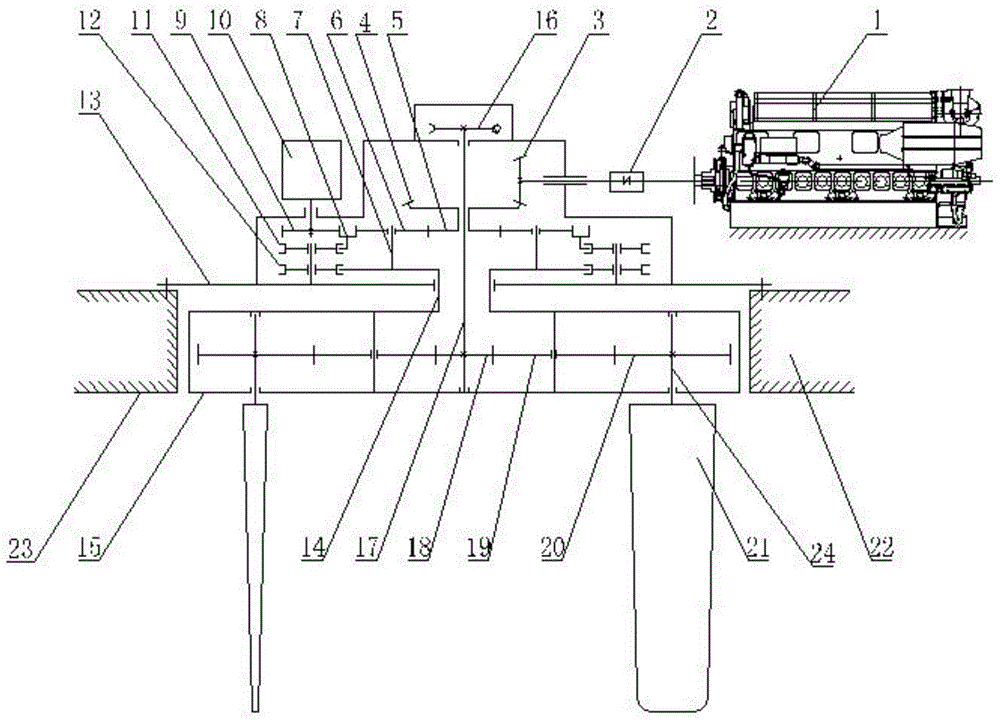

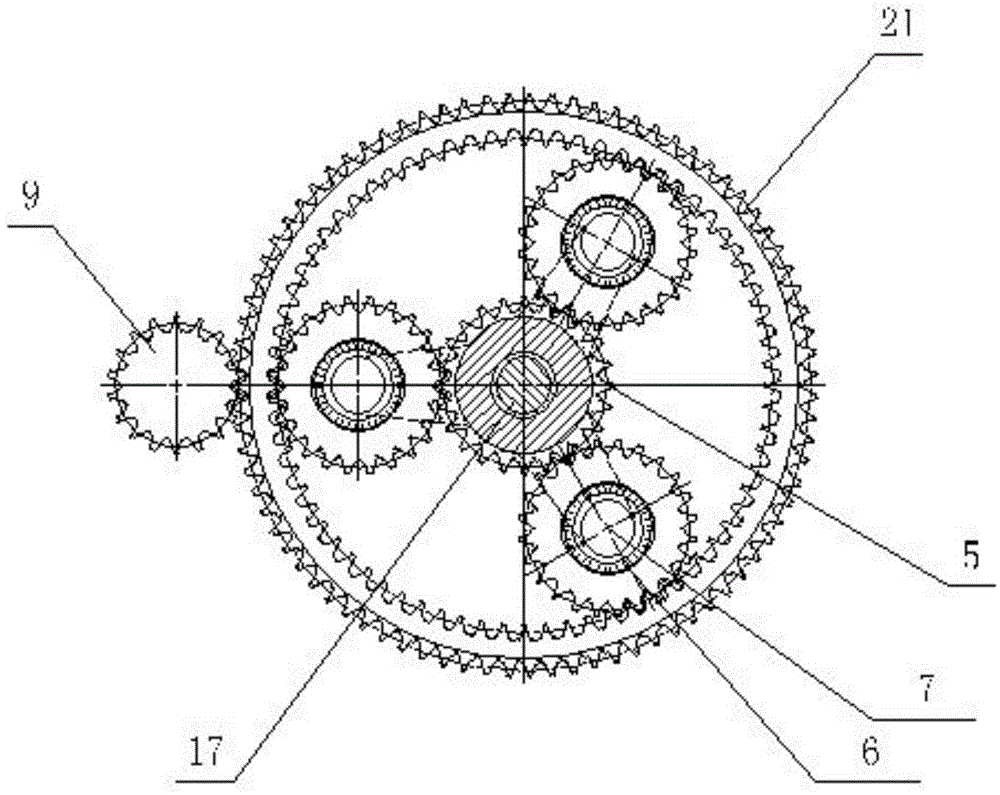

[0026] Such as figure 1 As shown, the constant-speed variable-pitch straight-wing omnidirectional propeller in this embodiment includes a coupling 2, an angle gear 3, a disc gear 4, a sun gear 5, a planetary gear 6, a planetary carrier 7, a ring gear 8, and a speed-regulating gear 9 , auxiliary power 10 (control motor), ring gear support wheel 11, planet carrier support wheel 12, machine base 13, main shaft 14, rotating disk 15, steering gear 16, rudder shaft 17, central gear 18, bridge gear 19, paddle The blade gear 20, the paddle 21 and the shaft 24, the output shaft of the main engine (diesel engine) 1 is interlocked with the angle gear 3 through the coupling 2, the angle gear 3 meshes with the disk gear 4, and the disk gear 4 is connected with the sun gear 5. move. Thus, the output shaft of the main engine (diesel engine) 1 can drive the angular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com