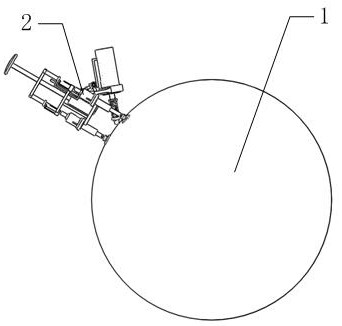

Intelligent portable oblique grooving machining device

A processing device and portable technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., which can solve the problems of prolonging the processing cycle, unable to slot, and unable to slot for handheld devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

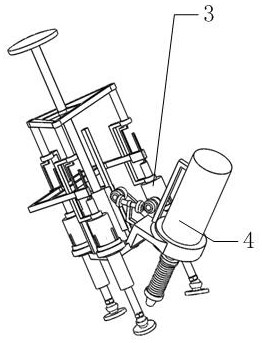

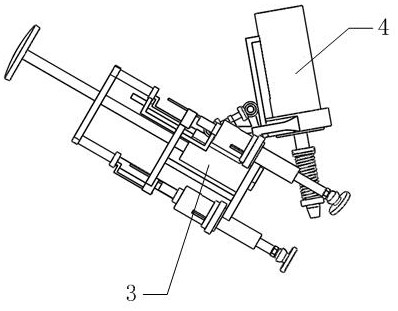

[0060] Embodiment: When using the grooved equipment 2 designed by the present invention, when in use, first press the equipment on the material surface of the grooved base 1, and then manually adjust the rotation adjustment screw 42 according to the material surface of the grooved base 1, By rotating the adjusting screw 42, the lengths of the adjusting screw 42 and the adjusting screw sleeve 39 can be adjusted under the action of the threads of the adjusting screw 42 and the adjusting screw sleeve 39, so that the chassis 41 installed on the adjusting screw 42 can be adapted to the material surface of the grooved base 1 , After the adjustment is completed, the top plate 29 is pressed down by the stomach, the top plate 29 drives the pressure rod 26 to move down, and the pressure rod 26 moves down through the bracket 27 to drive the first transmission rod 34 of the three legs 28 to move down, and the first transmission rod 34 moves down. The rod 34 drives the input rack 51 to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com