Automatic charging intelligent control device

An intelligent control and automatic loading technology, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of low degree of automation, cumbersome operation, single structure, etc., to improve work efficiency, speed up falling speed, increase The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

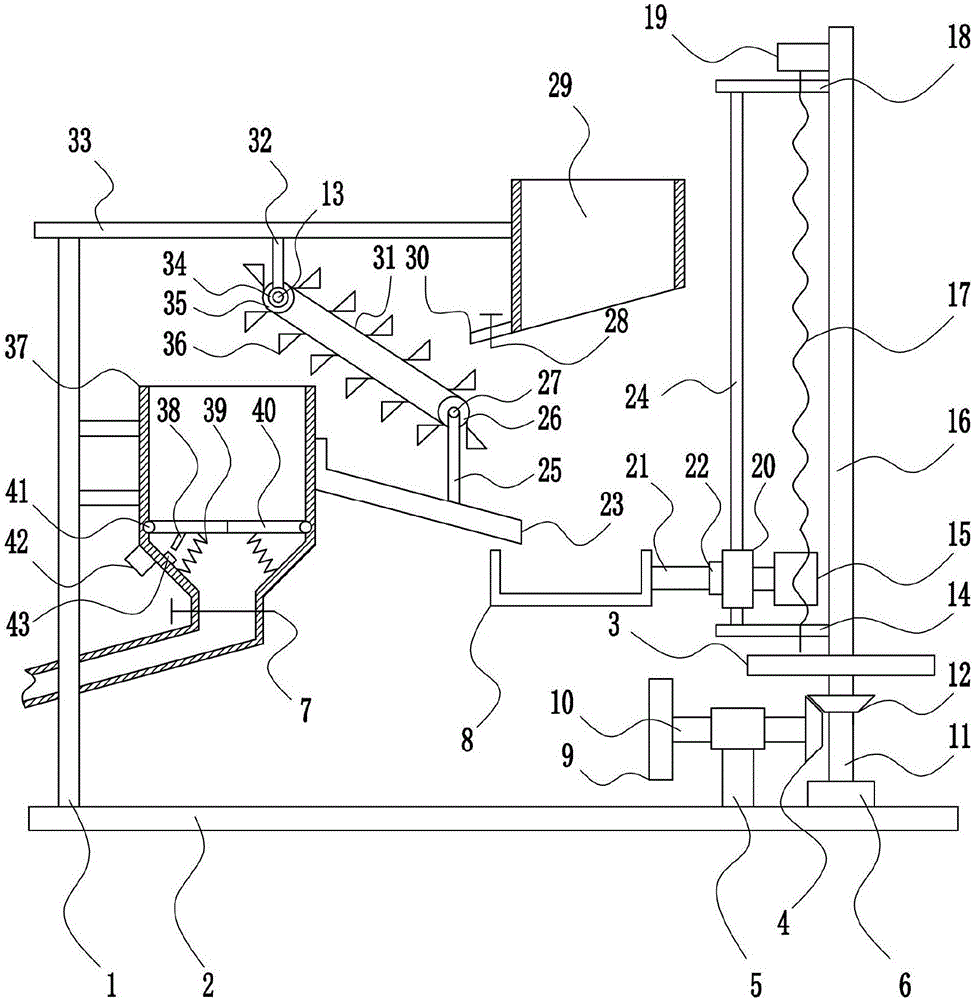

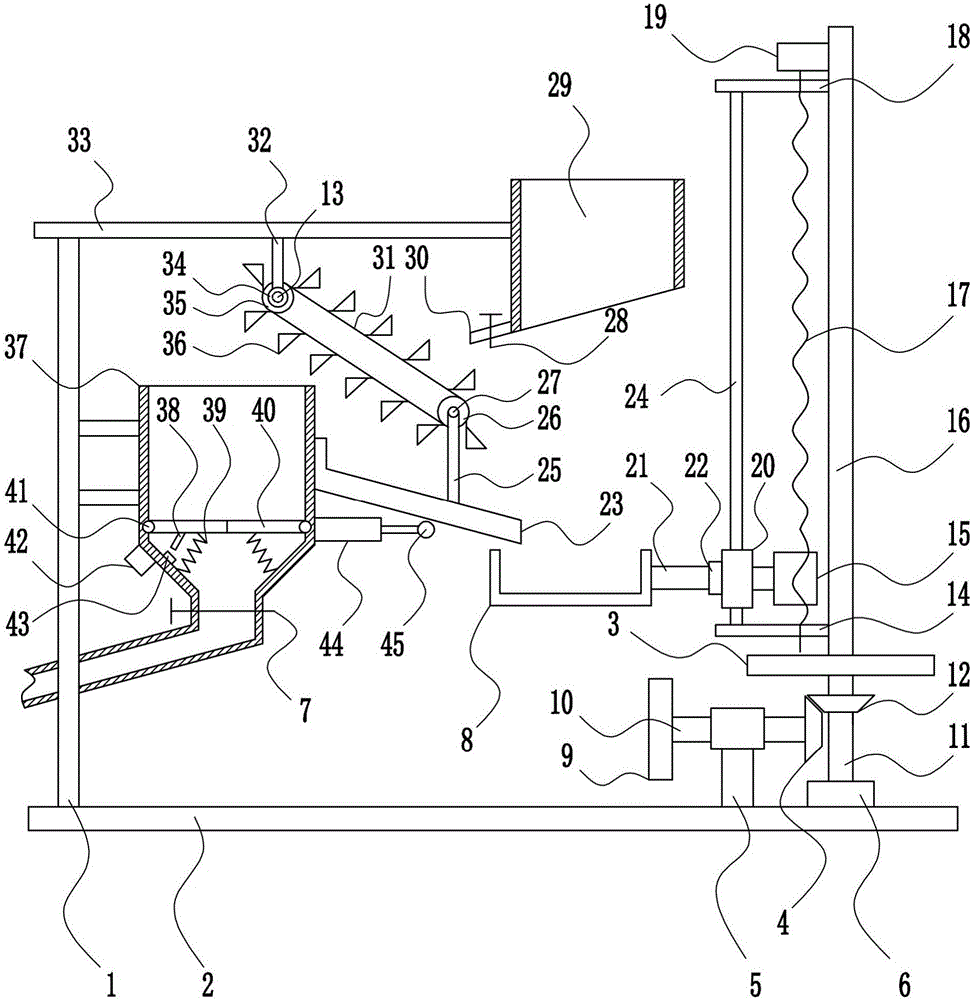

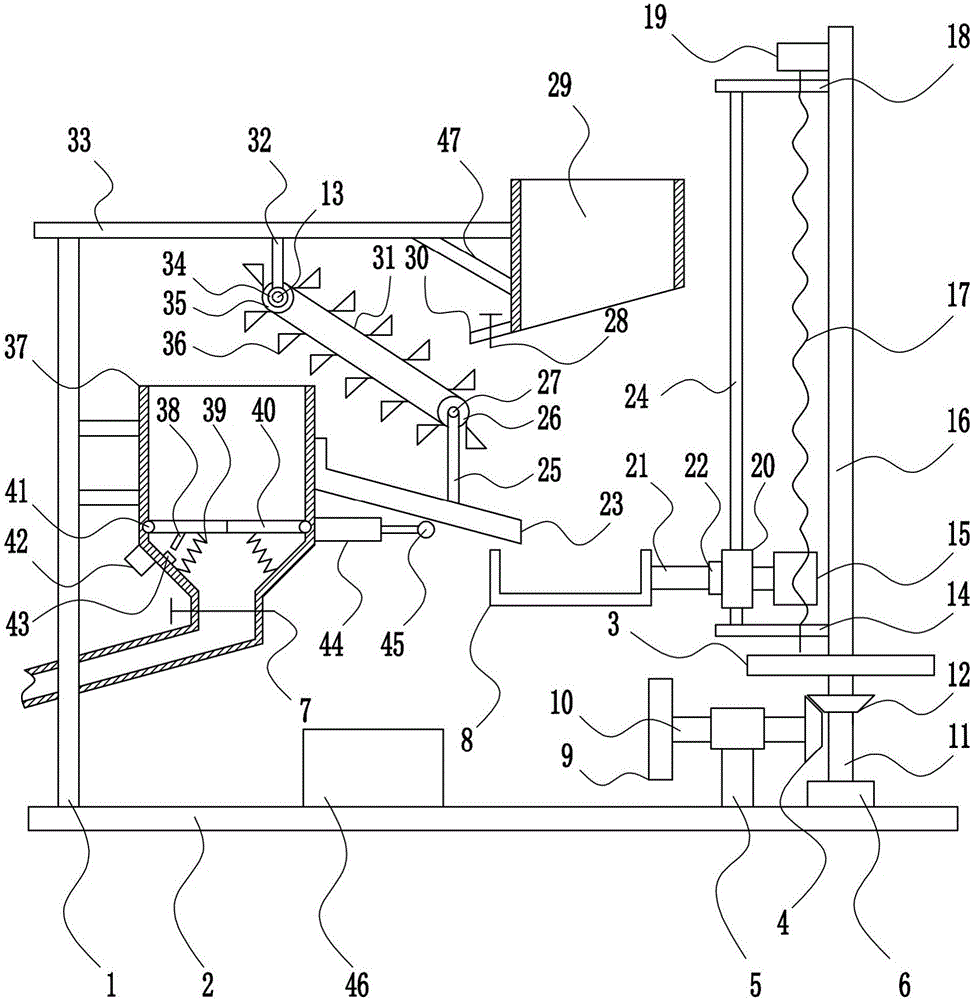

[0042] An automatic charging intelligent control device, such as Figure 1-6 As shown, it includes a left frame 1, a bottom plate 2, a first fixed plate 3, a first bevel gear 4, a first bearing seat 5, a second bearing seat 6, a first electric control valve 7, a collection frame 8, a turntable 9, First rotating shaft 10, second rotating shaft 11, second bevel gear 12, third rotating shaft 13, third bearing block 14, nut 15, second fixing plate 16, screw mandrel 17, fourth bearing block 18, first motor 19 , guide sleeve 20, fourth rotating shaft 21, fifth bearing seat 22, slideway 23, guide post 24, sixth bearing seat 25, first roller 26, fifth rotating shaft 27, second electric control valve 28, discharge box 29. Discharge port 30, conveyor belt 31, fixed rod 32, top plate 33, second motor 34, second roller 35, feeding frame 36, charging barrel 37, pressing block 38, elastic member 39, baffle plate 40, hinged parts 41. The controller 42 and the pressure sensor 43, the left fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com