Tread rubber for high thermal diffusivity semisteel car tire and tire

A car tire, high heat dissipation technology, applied to special tires, tire parts, vehicle components, etc., can solve problems such as tire blowout, tire wear, and impact on vehicle driving safety, and achieve low cost, good high-speed performance, and grip The effect of strong soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

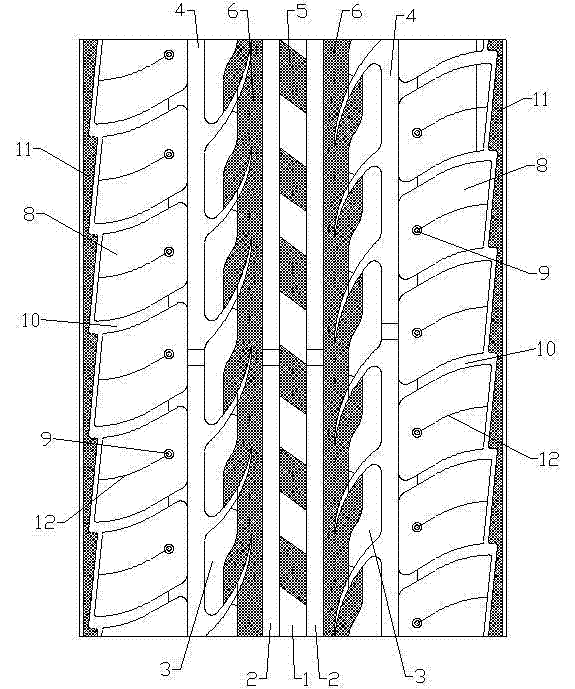

Image

Examples

Embodiment 1

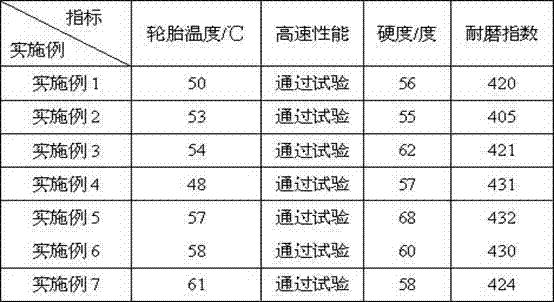

[0032] Embodiment 1, a tread rubber for semi-steel car tires with high heat dissipation, its effective raw materials and weight ratios are: 50 parts of natural rubber, 27 parts of high vinyl polybutadiene rubber, 23 parts of solution-polymerized styrene-butadiene rubber , 38 parts of polydimethylsiloxane, 1 part of dithiophosphate, 4 parts of zinc oxide, 3 parts of stearic acid, 0.1 part of anti-scorch agent CTP, 2 parts of microcrystalline wax, 6 parts of cycloalkane, cycloalkane 1 part cobalt alkanoate and 3 parts clay.

Embodiment 2

[0033] Embodiment 2, a kind of tread rubber for semi-steel car tires with high heat dissipation, its effective raw materials and weight ratio are: 50 parts of natural rubber, 28 parts of high vinyl polybutadiene rubber, 22 parts of solution-polymerized styrene-butadiene rubber , 30 parts of polydimethylsiloxane, 1 part of dithiophosphate, 4 parts of zinc oxide, 3 parts of stearic acid, 0.1 part of anti-scorch agent CTP, 2 parts of microcrystalline wax, 6 parts of cycloalkane, cycloalkane 1 part cobalt alkanoate and 3 parts clay.

Embodiment 3

[0034] Embodiment 3, a tread rubber for semi-steel car tires with high heat dissipation, its effective raw materials and weight ratio are: 50 parts of natural rubber, 25 parts of high vinyl polybutadiene rubber, 25 parts of solution-polymerized styrene-butadiene rubber , 40 parts of polydimethylsiloxane, 1 part of dithiophosphate, 4 parts of zinc oxide, 3 parts of stearic acid, 0.1 part of anti-scorch agent CTP, 2 parts of microcrystalline wax, 6 parts of cycloalkane, cycloalkane 1 part cobalt alkanoate and 3 parts clay.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com