Cathode active material, method for preparing the same, and lithium secondary batteries including the same

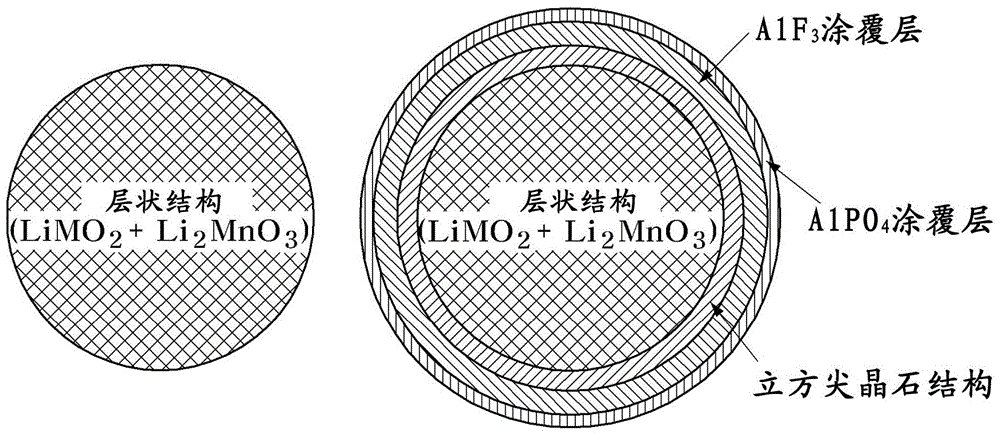

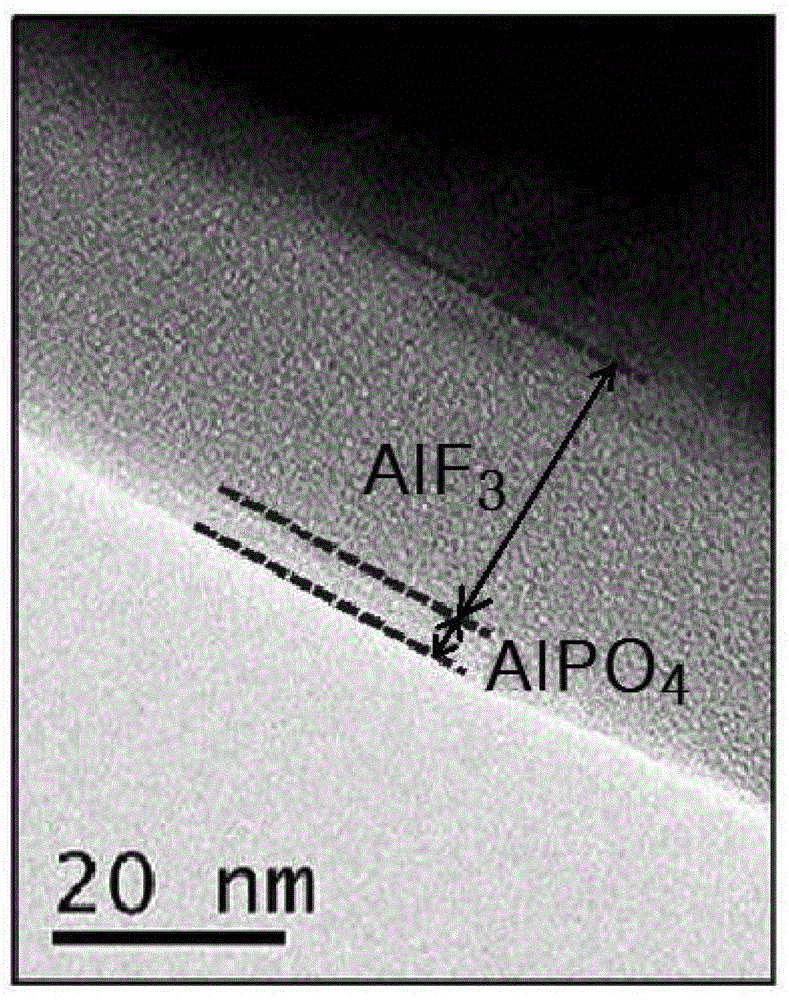

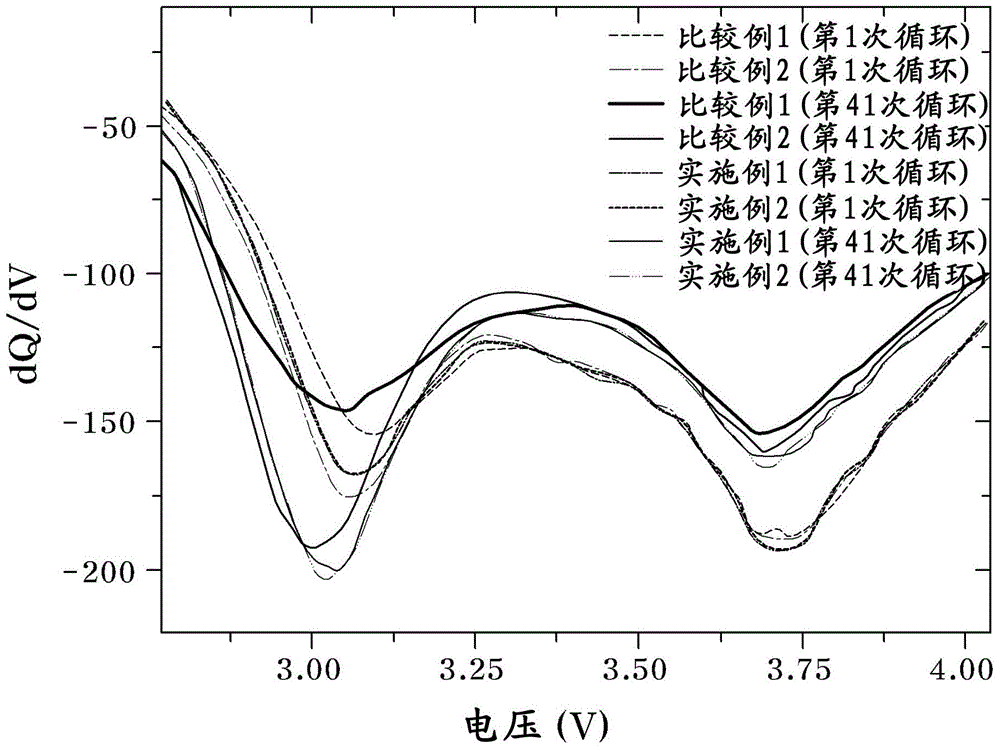

一种正极活性物质、二次涂覆的技术,应用在活性物质电极、锂蓄电池、非水电解质蓄电池等方向,能够解决涂敷效应未100%地展示、降低电化学特性等问题,达到改善高速性能和服务寿命特性、高容量、增强热稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] 2. Preparation method of positive electrode active material

[0062] The positive electrode active material of the present invention is prepared by a method for preparing a positive electrode active material, the method comprising: preparing a layered structure composite oxide having an excess of lithium manganese represented by the following formula: Li[Li x-z (Ni a co b mn c ) 1-x ]O 2-y f y (wherein, a+b+c=1, 0.05≤x≤0.33, 0≤y≤0.08 and 0

[0063] Production can be performed by various production methods such as a publicly known coprecipitation method and a sol-gel method by which a lithium-manganese-excess layered structure composite oxide is produced, and is not limited to any specific method.

[0064] The primary and secondary coatings can be performed by publicly known surface coating methods as long as ...

Embodiment 1

[0079] ①Synthesis of precursor

[0080] nickel sulfate (NiSO 4 ), cobalt sulfate (CoSO 4 ) and manganese sulfate (MnSO 4 ) was dissolved in water at a ratio of 2:2:6, and the resulting solution was then poured into a 1M sodium hydroxide (NaOH) solution. Ammonia (NH 4 OH) was slowly added to the aforementioned solution in an equivalent ratio equal to that of the metal solution. After the continuous type reactor was used to carry out the reaction for 12 hours or more, the formed precipitate was filtered, then washed several times with an aqueous solution, and dried in a drying oven at 120°C, thereby synthesizing Ni 0.2 co 0.2 mn 0.6 (OH) 2 precursor.

[0081] ② Synthesis of composite oxides with excess lithium manganese

[0082] The precursor nickel cobalt manganese hydroxide (Ni 0.2 co 0.2 mn 0.6 (OH) 2 ) and lithium carbonate (Li 2 CO 3 ) / lithium fluoride (LiF) were mixed at a stoichiometric ratio of 1:1.4, and then the mixture was baked at 700° C. to 900° C. for...

Embodiment 2

[0093] Preparation and evaluation were carried out in the same manner as in Example 1, the difference being that the concentration or material used for coating (0.8wt% AlF 3 +0.29wt%AlPO 4 ) changes, and the results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com