Single-color or multicolor double-layer warp-knitted spacer jacquard fabric and knitting method thereof

A warp-knitted, double-layer technology, which is applied to the single-color or multi-color double-layer spaced jacquard warp-knitted fabric and its weaving field, can solve the problem of poor air permeability, inability to obtain double-sided jacquard, ultra-thin effect jacquard woven vamp, and inability to Solve problems such as irregular connection, and achieve the effect of balance of warp let-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A warp knitted fabric is woven on a double-needle-bar Jacquard warp knitting machine, and the knitting method comprises the following steps:

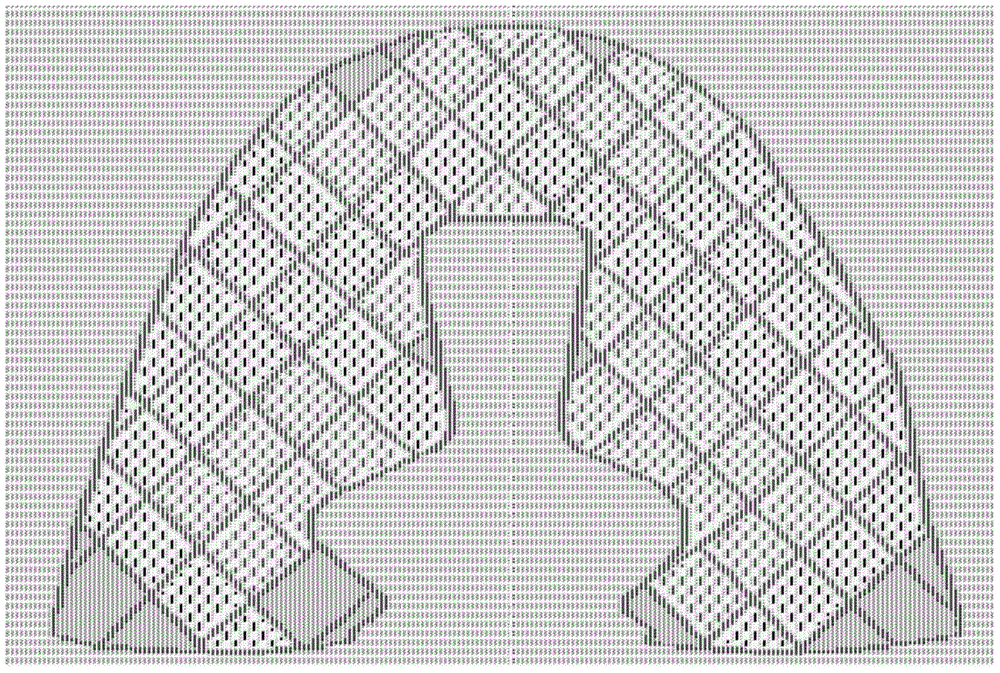

[0050] (1) Use computer to design the jacquard pattern of the warp knitted fabric, such as figure 1 shown;

[0051] (2) Preparation for knitting: The warp knitting machine is equipped with six guide bars, which are arranged sequentially from the front of the machine to the rear of the machine: bar GB1, Jacquard bar JB2, Jacquard bar JB3, Jacquard bar JB4, Jacquard bar JB5 and bar GB6, of which:

[0052] A) Bars GB1 and GB6 use full gauge guide needle blocks; Jacquard bar JB2, Jacquard bar JB3, Jacquard bar JB4 and Jacquard bar JB5 use half gauge guide needles piece;

[0053] B) The needles of the jacquard bar GB1 and the jacquard bar GB6 are full of yarns; the needles on the jacquard bar JB2, jacquard bar JB3, jacquard bar JB4 and jacquard bar JB5 all wear 238 yarns Yarn, half of the needles are threaded and half of the needl...

Embodiment 2

[0059] A warp knitted fabric is woven on a double-needle-bar Jacquard warp knitting machine, and the knitting method comprises the following steps:

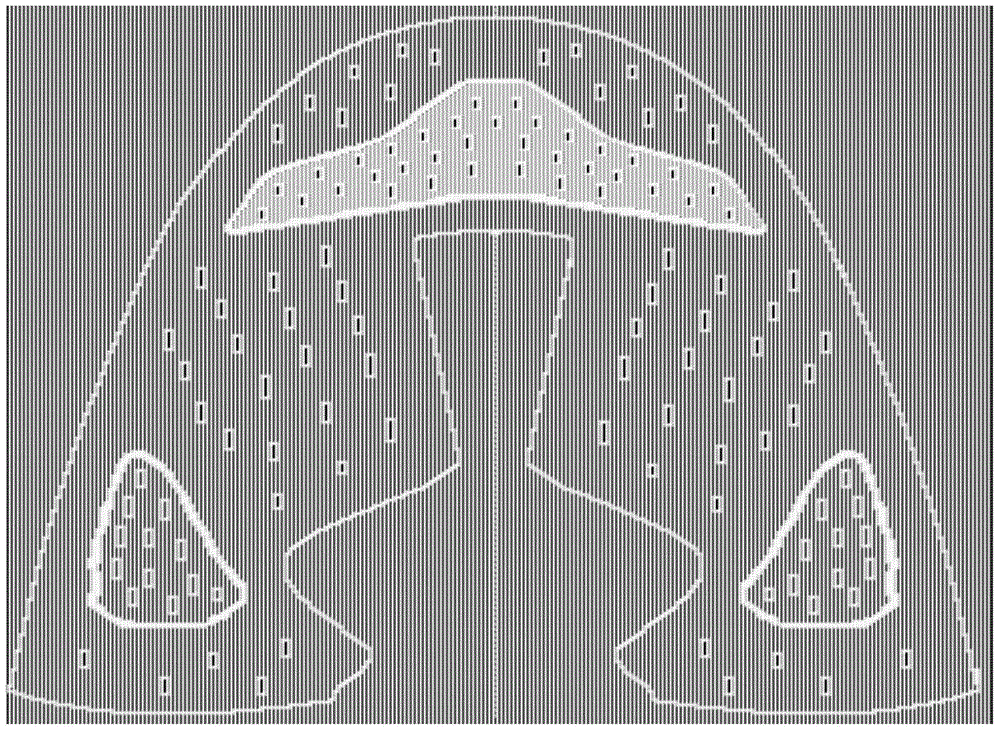

[0060] (1) Use computer to design the jacquard pattern of the warp knitted fabric, such as figure 2 shown;

[0061] (2) Preparation for knitting: The warp knitting machine is equipped with six guide bars, which are arranged sequentially from the front of the machine to the rear of the machine: bar GB1, Jacquard bar JB2, Jacquard bar JB3, Jacquard bar JB4, Jacquard bar JB5 and bar GB6, of which:

[0062] A) Bars GB1 and GB6 use full gauge guide needle blocks; Jacquard bar JB2, Jacquard bar JB3, Jacquard bar JB4 and Jacquard bar JB5 use half gauge guide needles piece;

[0063] B) The needles of the jacquard bar GB1 and the jacquard bar GB6 are full of yarns; the needles on the jacquard bar JB2, jacquard bar JB3, jacquard bar JB4 and jacquard bar JB5 all wear 238 yarns Yarn, half of the needles are threaded with yarn and half o...

Embodiment 3

[0070] A warp knitted fabric is woven on a double-needle-bar Jacquard warp knitting machine, and the knitting method comprises the following steps:

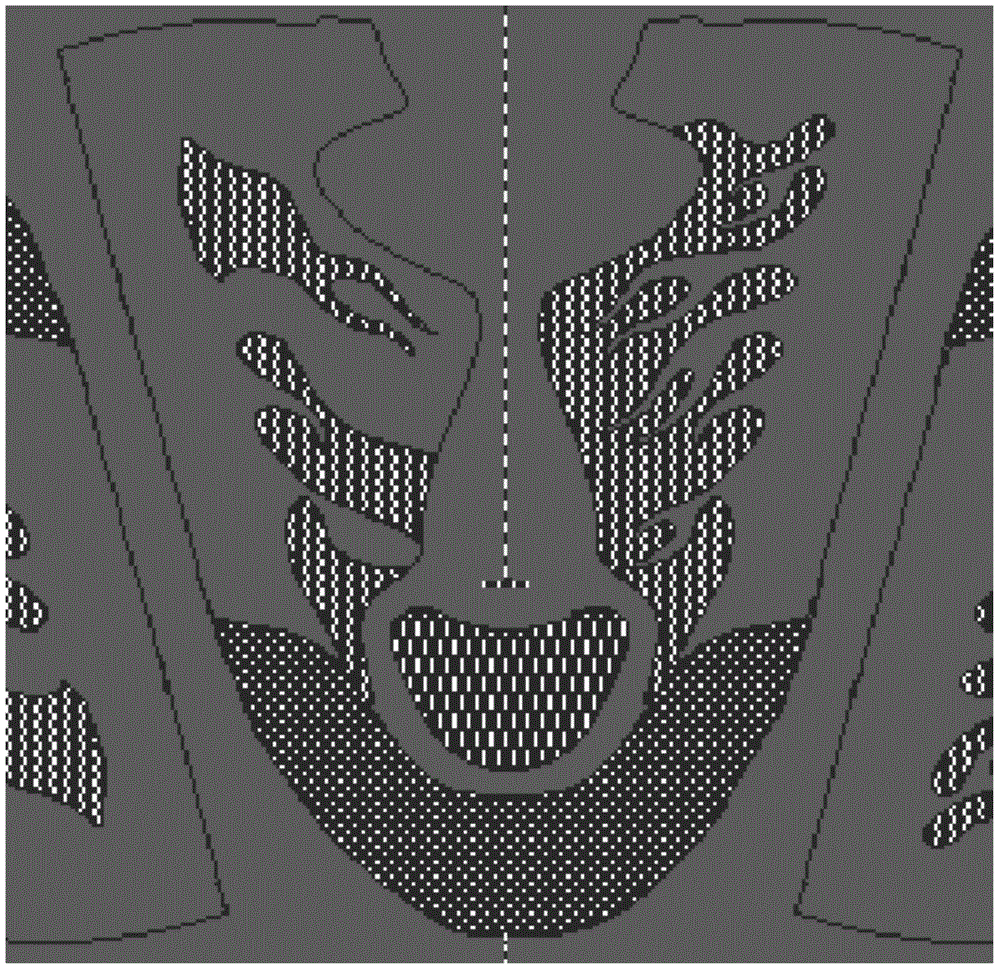

[0071] (1) Use computer to design the jacquard pattern of the warp knitted fabric, such as image 3 shown;

[0072] (2) Preparation for knitting: The warp knitting machine is equipped with seven guide bars, which are arranged sequentially from the front of the machine to the rear of the machine: bar GB1, Jacquard bar JB2, Jacquard bar JB3, Jacquard bar JB4, Jacquard bar JB5, bar GB6 and bar GB7, of which:

[0073] A) Bars GB1, GB6 and GB7 use full gauge guide needle blocks; Jacquard bars JB2, Jacquard bars JB3, Jacquard bars JB4 and Jacquard bars JB5 use half gauges guide needle block;

[0074]B) The needles of the bar GB1, GB6 and GB7 are fully threaded through the yarn; the needles on the Jacquard bar JB2, JB3, JB4 and Jacquard bar JB5 238 yarns are worn on average, half of the needles are threaded and half of the needles a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com