Two-needle bar electronic Jacquard warp knitting machine

A double-needle bed and electronic technology, applied in warp knitting, knitting, textiles and papermaking, etc., can solve the problems of difficult manufacturing, low precision, unsuitable for high speed, etc., and achieve convenient pattern change, high precision, and simplified structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

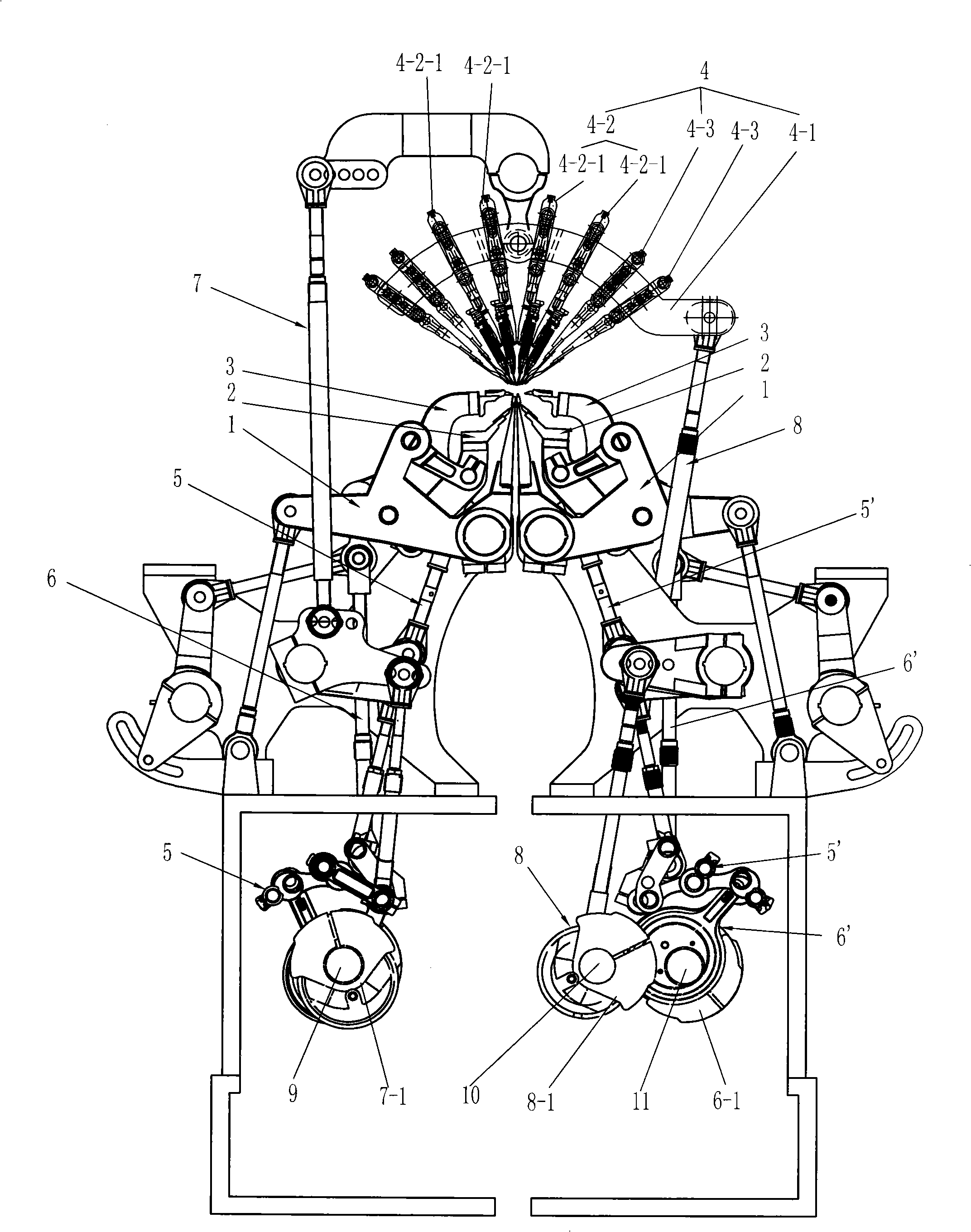

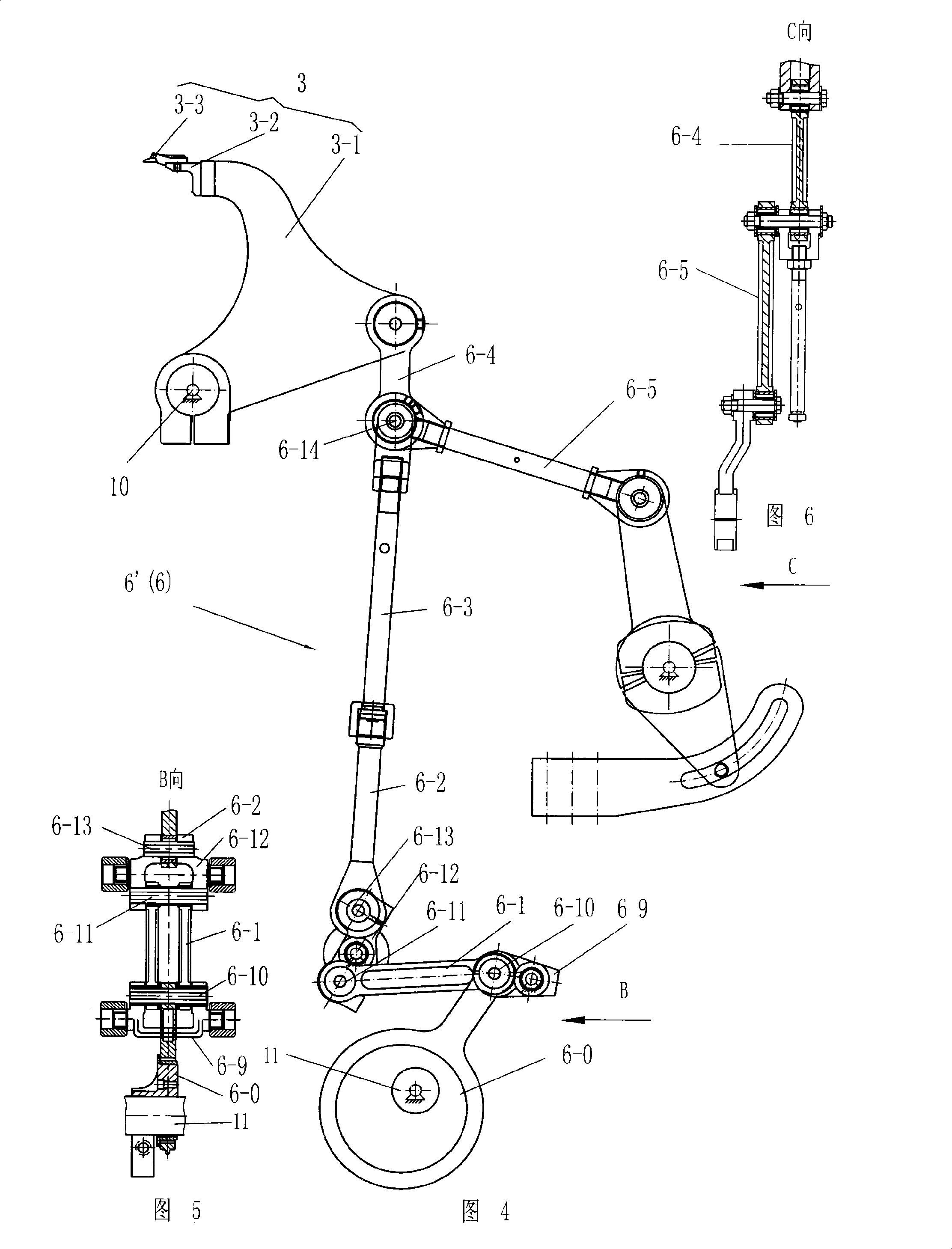

[0026] Figures 1 to 1 The embodiment shown in 0 includes a loop forming device, a bar device and a transmission device. The knitting device includes symmetrical front and rear knock-off parts 1 , front and rear needle bed parts 2 and symmetrical front and rear settling parts 3 . The transmission device includes symmetrical front and rear needle bed transmission mechanisms 5, 5', symmetrical front and rear sinking transmission mechanisms 6, 6', bar cradle up swing transmission mechanism 7 and bar cradle bottom swing transmission mechanism 8 .

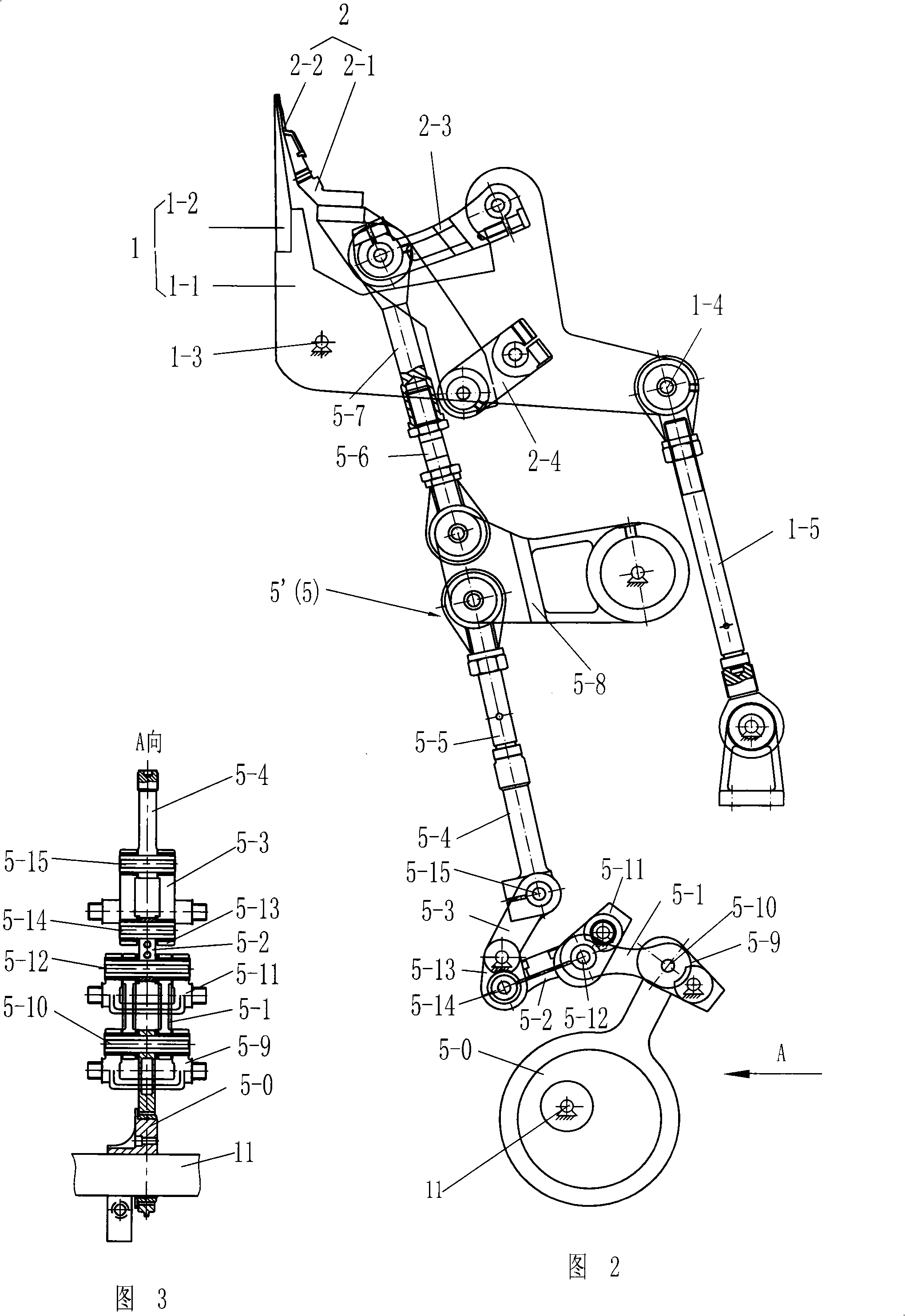

[0027] See Fig. 2 to 3, front and rear stripping part 1 respectively comprise the stripping support 1-1 that is connected on the frame and the stripping needle bed 1-2 that is connected on the stripping support 1-1, front and rear needle The parts of the bed part 2 each include a latch needle bed 2-1 which is dynamically connected to the tripping bracket 1-1 through upper and lower connectors 2-3, 2-4 and a latch needle bed 2-1 instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com