A warp knitting method for double-color jacquard seamless fabric

A seamless fabric and warp knitting technology, applied in the directions of warp knitting, knitting, textiles and papermaking, etc., can solve the problems of inconspicuous main pattern effect and single color of seamless fabric, achieve rich patterns and colors, and achieve perfect connection , the effect of enriching the organizational structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Taking the knitting of a nylon seamless pantyhose as an example, the implementation is divided into the following steps.

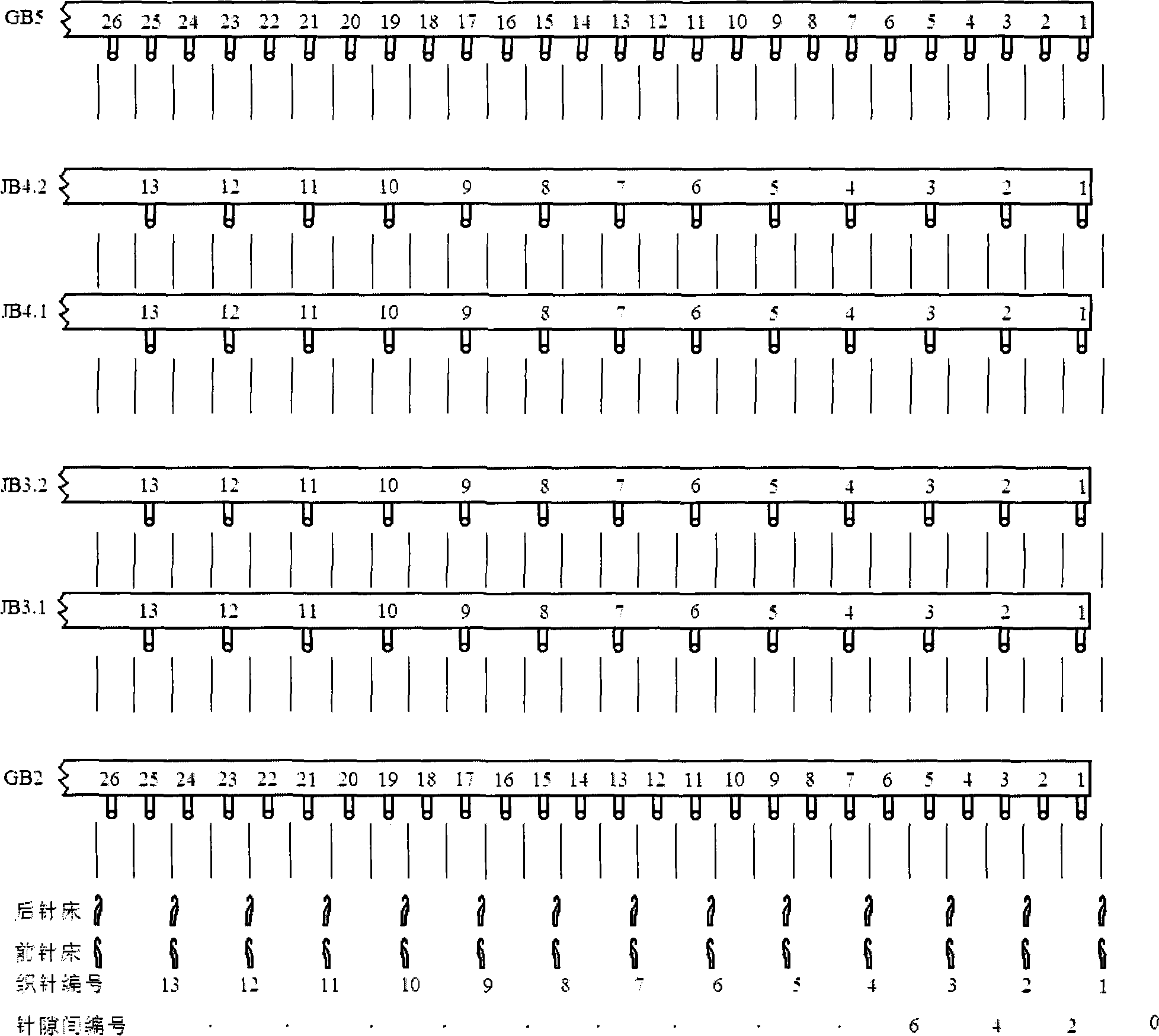

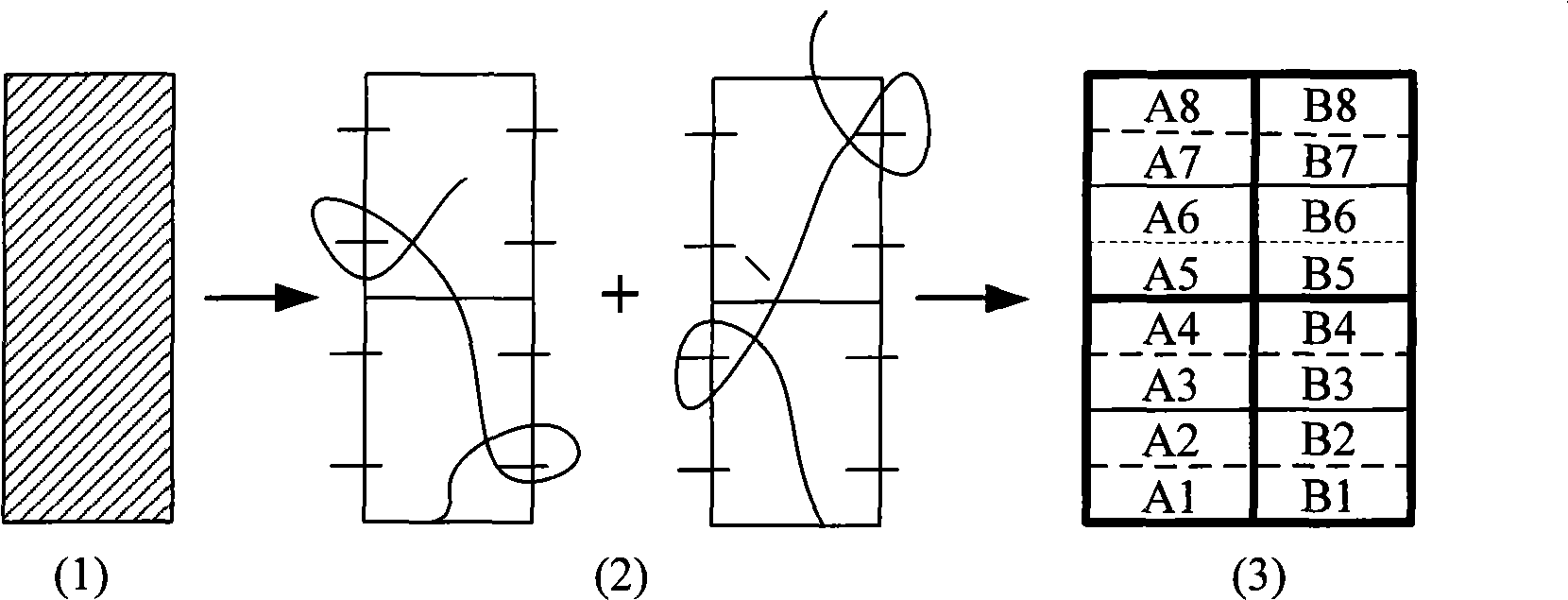

[0042] Such as figure 1 As shown, the pre-preparation work is as follows: (1) Standing in front of the machine and facing the machine as the judgment benchmark for the direction; (2) Use two, four or six comb bars, of which 2 are separate Jia The card combs are arranged in half-gauge relative to form 4 half-gauge jacquard bars, which are located in the middle and arranged symmetrically; (3) The knitting needles on the needle bed are 1 loaded and 1 empty, from the direction of the machine head (right) to the machine tail Direction (left), so the needle gaps are numbered 0, 2, 4... Number the gaps, this number can be used as a description of the lapping movement.

[0043] a. Select raw materials:

[0044] Front needle bed comb GB2: 56dtex (40f) nylon

[0045] Front needle bed jacquard comb JB3.1: 56dtex (40f) nylon + 22dtex spandex covered yarn

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com