High-strength, flame-retardant and high-temperature-resistant polyimide yarn and manufacturing method thereof

A technology of polyimide yarn and high temperature resistant type is applied in the field of high-strength flame retardant and high temperature resistant polyimide yarn and its preparation field, which can solve the problem of uneven adhesion of treatment agents, increase the difficulty of fabric preparation, and increase the yield of fabrics. low problems, to achieve the effect of reducing hairiness, high temperature resistance and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

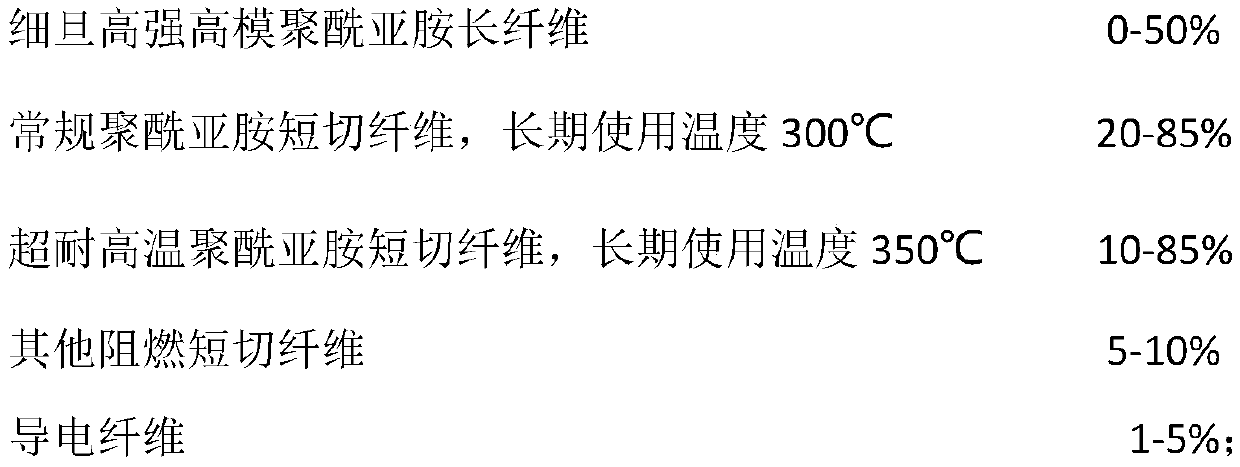

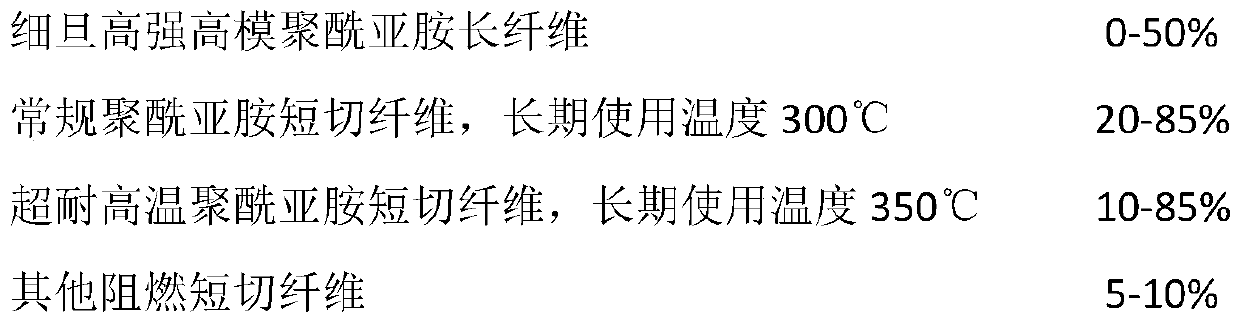

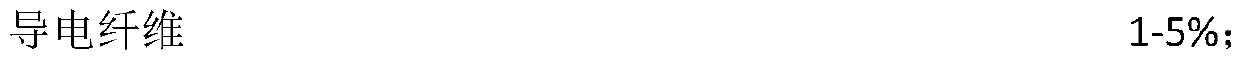

[0032] A high-strength flame-retardant and high-temperature-resistant polyimide yarn and a preparation method thereof, comprising the following steps:

[0033] a. Conventional polyimide chopped fiber, ultra-high temperature resistant polyimide chopped fiber, meta-aramid chopped fiber, aramid fiber surface metallized conductive fiber are mixed in a weight ratio of 50:25:10:5 Finally, use the mixed solution of antistatic agent F695 and water, the mass ratio is 1:20 to carry out pretreatment, after processing, let it stand for 24h;

[0034] b. Cotton cleaning-carding-drawing-roving;

[0035] c. spun yarn is made from roving, while 10% fine denier, high-strength and high-modulus polyimide fiber (≥20.8cN / dtex) is twisted and wound with spun yarn at the front jaw of the spinning frame to prepare core-spun yarn;

[0036] d. The polyimide yarn prepared in step c is treated with 1.5wt% silicone water-based emulsion after sizing, dried, heat-set twist, and wound into a yarn to obtain a...

Embodiment 2

[0038] The post-treatment agent is a mixed aqueous emulsion of polyvinyl alcohol and silicone, wherein the molar ratio of polyvinyl alcohol to silicone is 5:1, and the others are the same as in Example 1.

Embodiment 3

[0040] The post-treatment agent is a mixed aqueous emulsion of polyvinyl alcohol and silicone, wherein the molar ratio of polyvinyl alcohol to silicone is 8:1, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com