Electronic-grade glass fiber yarn secondary slurry, glass fiber yarn covered with secondary slurry and corresponding glass fiber cloth

A technology of glass fiber yarn and glass fiber cloth, applied in the field of glass fiber sizing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

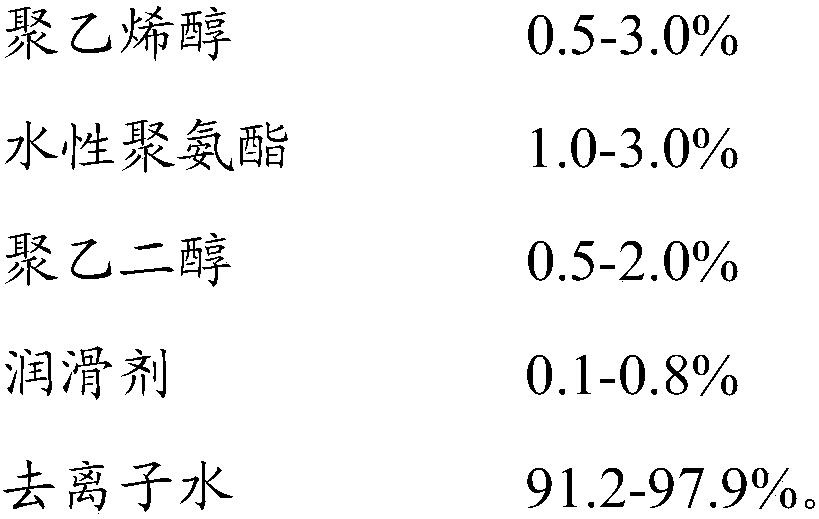

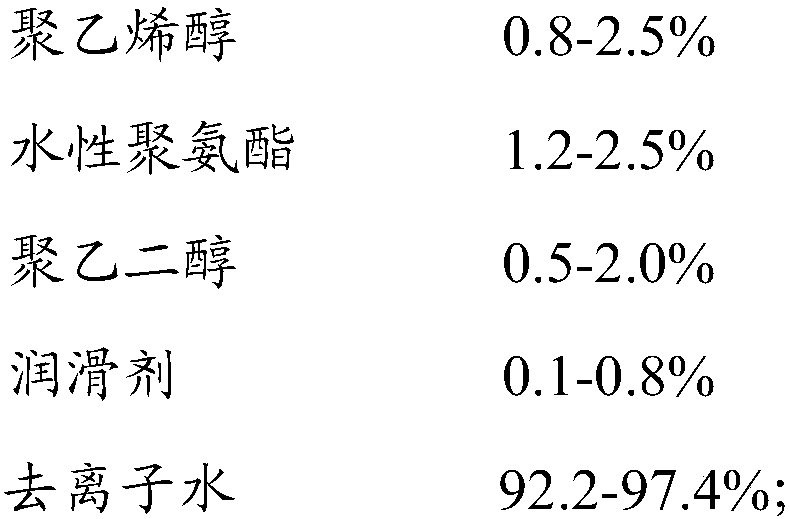

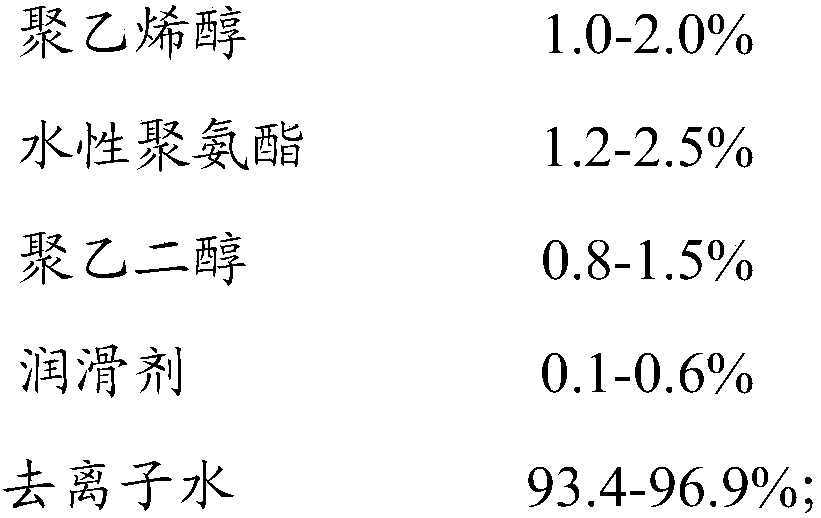

Method used

Image

Examples

Embodiment 1-5

[0061] Weigh each component by mass percentage, respectively weigh 1.52% polyvinyl alcohol, 1.38% water-based polyurethane, 0.92% polyethylene glycol, 0.18% lubricant and 95.8% deionized water. in:

Embodiment 1

[0063] The degree of alcoholysis of polyvinyl alcohol is 98%, the degree of polymerization is about 1700, produced by Taiwan Changchun Chemical Company, the model is BF-17; polyethylene glycol is produced by Dow Chemical in the United States, the model is PEG4000, the molecular weight is 4000; lubricant The non-ionic microcrystalline wax lubricant produced by Michelman Company, the model is LUBE723; the water-based polyester polyurethane was purchased from the No. 1 Branch Factory of Jushi Group.

Embodiment 2

[0065] The degree of alcoholysis of polyvinyl alcohol is 88%, the degree of polymerization is about 500, produced by Taiwan Changchun Chemical Company, the model is BG-05; polyethylene glycol is produced by Dow Chemical in the United States, the model is PEG1500, the molecular weight is about 1500; lubrication The lubricant is non-ionic microcrystalline wax lubricant produced by Michelman Company, the model is LUBE723; the water-based polyester polyurethane is purchased from the first branch of Jushi Group.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com