Method for pretreating gelatin by liming

A pretreatment and liming technology, which is applied in the field of liming pretreatment of gelatin prepared by alkaline method, can solve the problems of capillary channel shrinkage, bone bone blockage, and bone bone difficult to separate, so as to improve liming efficiency and reduce oil content, shortening the effect of liming cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

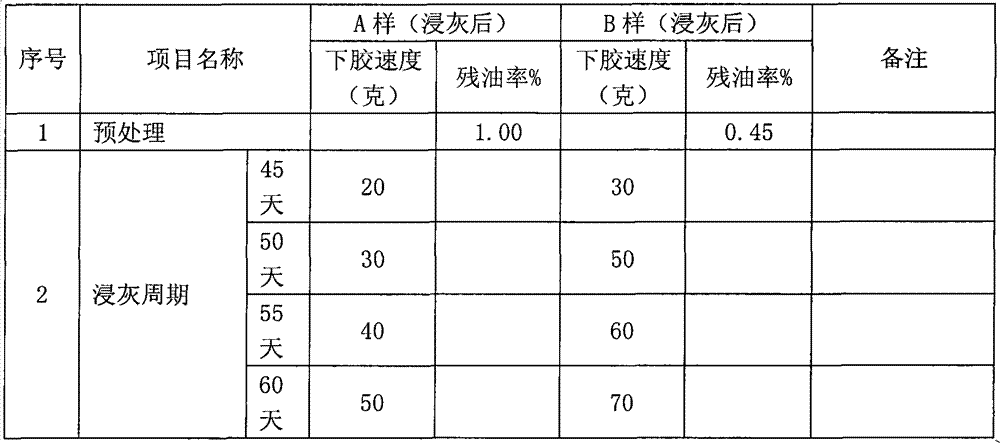

[0022] Embodiment 1 gelatin liming pretreatment

[0023] 1. Pickling and washing

[0024] Pickling and washing can be carried out according to existing conventional methods. Specifically, the aggregate is processed into bone grains with a particle size of 10-15 mm, soaked in hydrochloric acid with a concentration of 4%, and the amount of hydrochloric acid passing through per ton of bone grains per hour is 400L. When the concentration of soaked hydrochloric acid remains unchanged (96h), it reaches a plateau and maintains a plateau for 24 hours. It is detected that the minerals are basically depleted, and the aggregate is soft and elastic. Wash with water until pH > 3.5.

[0025] 2. Liming pretreatment

[0026] Add 3% dilute ammonia solution to the acid-soaked bone bone (washed to pH 3.6) that has passed the water washing, and agitate with compressed air to make the bone bone and the solution evenly mixed, and react for 24 hours. Agitate with compressed air every 2 hours. A...

Embodiment 2

[0027] Embodiment 2 gelatin liming pretreatment

[0028] Add 4% dilute ammonia solution to the washed osteoin pH 3.8, agitate with compressed air to mix the osteoin and the solution evenly, and react for 36 hours. Agitate with compressed air every 3 hours. After the reaction is over, remove the residual liquid and wash with water 3 times. The reacted bone is called G1. Mix 4% dilute ammonia solution and 0.8% hydrogen peroxide solution at a ratio of 1:1 to form a mixture and add it to G1 to react for 36 hours, agitating with compressed air every 3 hours. After the reaction is over, remove the residual liquid and wash with water 3 times. The reacted bone is called G2. According to this procedure, the osteotin and the mixed solution were reacted 3 times, and the liming pretreatment was completed after washing with water.

Embodiment 3

[0029] Embodiment 3 gelatin liming pretreatment

[0030] Add 5% dilute ammonia solution to the washed osteoin pH 4.0, agitate with compressed air to mix the osteoin and the solution evenly, and react for 48 hours. Agitate with compressed air every 4 hours. After the reaction is over, remove the residual liquid and wash with water 4 times. The reacted bone is called G1. Mix 5% dilute ammonia solution and 1% hydrogen peroxide solution at a ratio of 1:1 to form a mixture and add it to G1 to react for 48 hours, agitating with compressed air every 4 hours. After the reaction is over, remove the residual liquid and wash with water 4 times. The reacted bone is called G2. According to this procedure, the osteotin and the mixed solution were reacted 4 times, and the liming pretreatment was completed after washing with water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com