A kind of gf/pp composite fiber sizing agent and its application

A composite fiber and sizing technology, which is applied in the direction of fiber treatment, fiber type, wear-resistant fiber, etc., can solve the problem of not mentioning the color status of the final composite product, poor adhesion of polypropylene fiber, and poor performance of composite materials and other problems, to achieve the effects of smooth hand feeling, improved post-processing efficiency, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

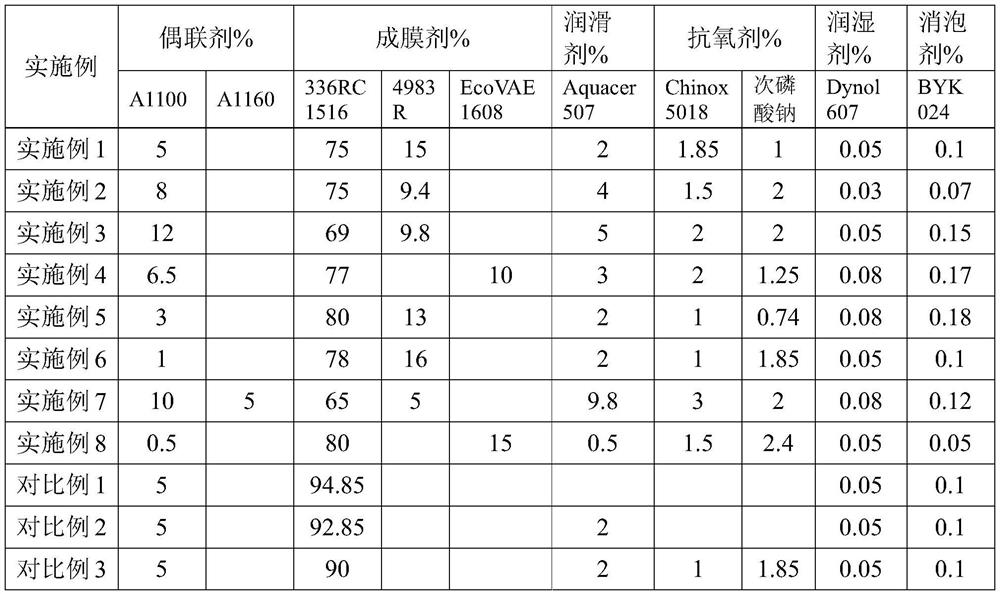

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention is described with the following specific examples, but it is by no means limited thereto. The following description is a preferred embodiment of the present invention, which is only used to describe the present invention, and should not be construed as a limitation of the present invention. It should be pointed out that any modifications, equivalent replacements and improvements made within the spirit and principles of the present invention , should be included within the protection scope of the present invention.

[0030] The wetting agent used in the following examples includes the following components:

[0031] The coupling agent grades are: American Momentive Advanced Materials Group A1100 (γ-aminopropyltriethoxysilane), A1160 (γ-ureapropyltrialkoxysilane)

[0032] The grade of the main film-forming agent is: German BYK Chemical Co., Ltd. 336RC1516...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com