PTFE (Polytetrafluoroethylene) material for glass fiber coating and bundling device and preparation method thereof

A clustering device and glass fiber technology, which is applied in the field of glass fiber coating clustering devices, can solve the problems of easily polluted glass fibers, low friction coefficient, and high hairiness, so as to ensure coating uniformity, low friction coefficient, and reduce hairiness volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

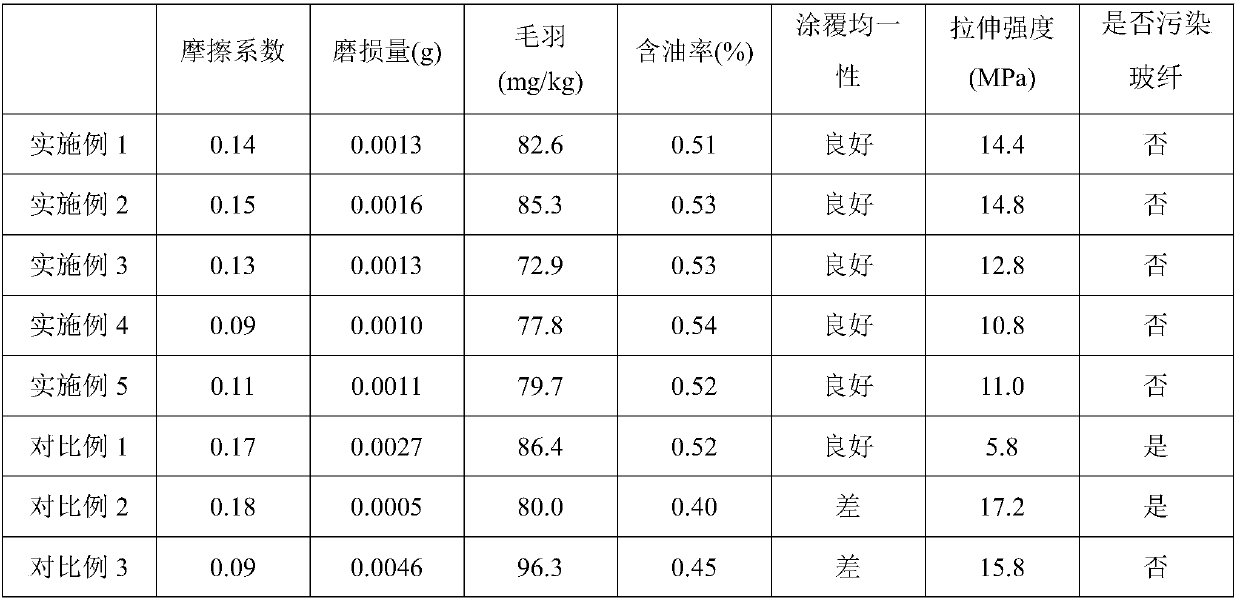

Examples

Embodiment 1

[0025] Weighing: 9 kg of polytetrafluoroethylene, 1 kg of modified polytetrafluoroethylene, 1 kg of silicon dioxide, and 2 kg of polyimide.

[0026] Put PTFE, silicon dioxide and polyimide into a high-speed mixer and mix evenly to obtain a compound. Then the mixture is added into the mold for compression molding, and the pressure is 40MPa. Then it is sintered into a blank, the sintering temperature is 350-380 degrees, and the material product is obtained after natural cooling.

Embodiment 2

[0028] Weighing: 8 kg of polytetrafluoroethylene, 2 kg of modified polytetrafluoroethylene, 2 kg of molybdenum disulfide, and 2 kg of polyimide.

[0029] Put PTFE, graphite, and polyetheretherketone into a high-speed mixer and mix them evenly to obtain a mixture. Then the mixture is added into the mold for compression molding, and the pressure is 40MPa. Then it is sintered into a blank, the sintering temperature is 350-380 degrees, and the material product is obtained after natural cooling.

Embodiment 3

[0031] Weighing: 7 kg of polytetrafluoroethylene, 3 kg of modified polytetrafluoroethylene, 3 kg of graphite, and 1 kg of polyimide.

[0032] Put PTFE, graphite, and polyimide into a high-speed mixer and mix them evenly to obtain a mixture. Then the mixture is added into the mold for compression molding, and the pressure is 40MPa. Then it is sintered into a blank, the sintering temperature is 350-380 degrees, and the material product is obtained after natural cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com