Novel colored spun yarn production method

A production method and color spinning technology, which are applied to spinning machines, continuously wound spinning machines, yarns, etc., can solve the problems of inability to achieve scaly effect fabrics, few types of fancy yarns, etc., and achieve a compact structure. , Unique style, smooth yarn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Adopt this white cotton, after catching cotton, cotton blending, cotton opening, coiling, carding, drawing frame and roving process, produce white roving A, quantitatively is 3.5 grams / 10 meters. Adopt the black cotton that dyeing process, adopt same method, make the roving B that color is black, quantification is 3.5 grams / 10 meters.

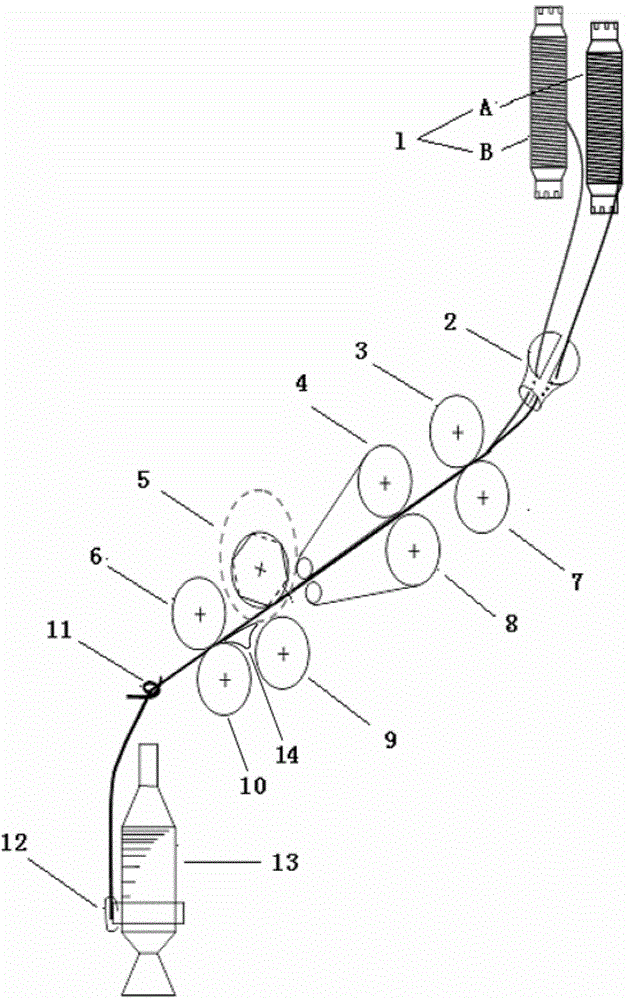

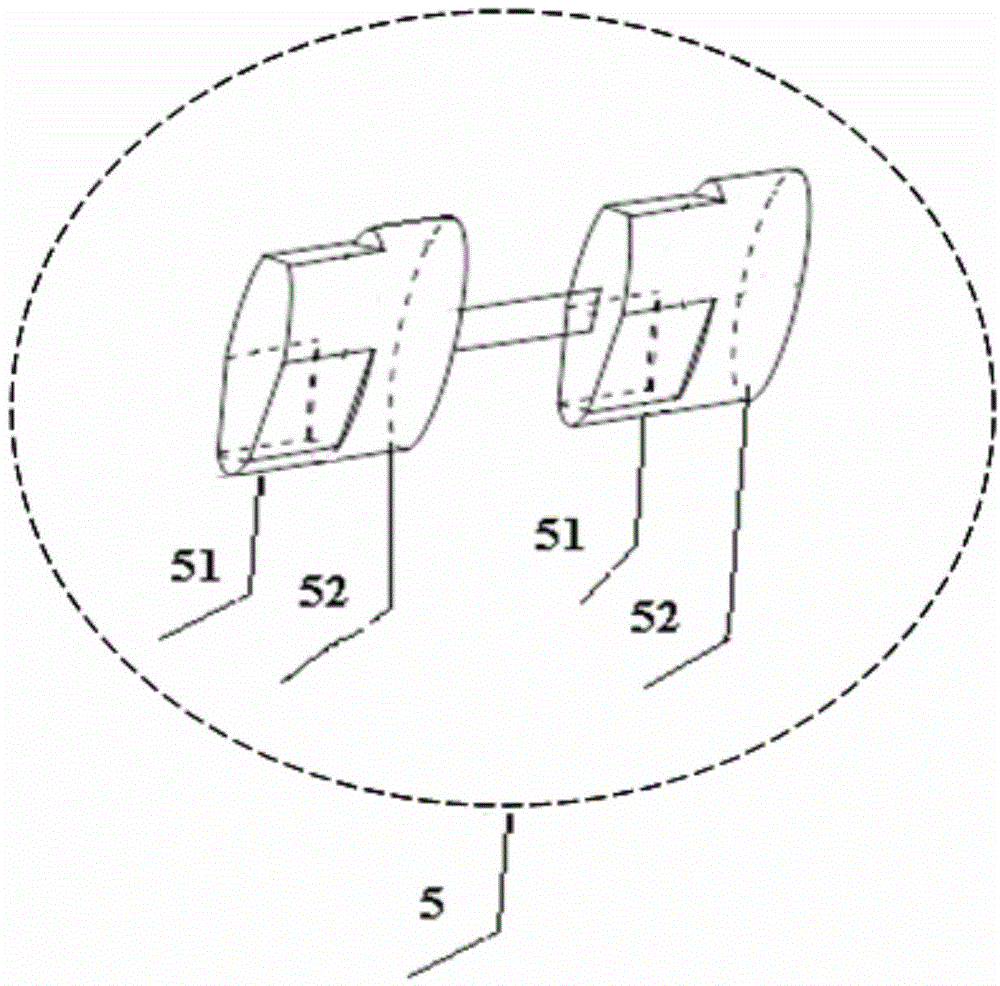

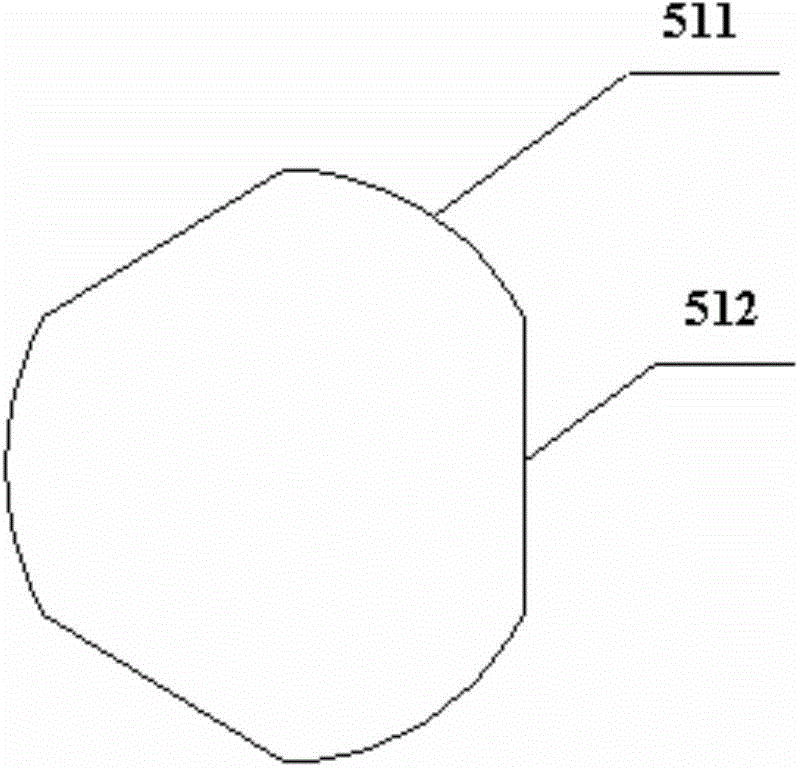

[0055]The roving A and roving B are respectively fed into the left hole and the right hole of the double-hole bell mouth of the Siro compact spinning machine, and then pass through the rear roller 7, the middle roller 4, the front roller 9, the accumulation roller 10, the guide hook 11 and the steel wire The ring 12 is wound on the spun bobbin 13, and the front roller 9 corresponds to a front top roller 5 for holding the roving A and / or roving B. The front top roller 5 includes a part 51 and a part b along the axial direction. Part 52, wherein part a 51 accounts for 30-50% of the length of the front top roller 9, and the cross-sections o...

Embodiment 2

[0063] Adopt dyed and processed red cotton, after plucking, blending, opening, coiling, carding, drawing and roving processes, white roving A is produced, with a quantitative value of 3.5 grams / 10 meters. Adopt the yellow cotton that dyeing process, adopt same method, make the roving B that color is black, quantification is 3.5 grams / 10 meters.

[0064] Such as figure 1 with figure 2 As shown, the roving A and the roving B are respectively fed into the left hole and the right hole of the bell mouth of the Siro compact spinning machine, and are wound on the On the spun bobbin, the front roller corresponds to a front top roller for holding the roving A and the roving B, and the front top roller 5 includes a part 51 and a part b 52 along the axial direction, wherein the part a 51 occupies 30~50% of the length of the front top roller 9, and the cross sections of the a part 51 are consistent, the cross section of the a part 51 is a nearly regular hexagon, and the sides of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com