Novel spinning device

A new type of spinning frame technology, applied in spinning machines, textiles, papermaking, drafting equipment, etc., can solve the problems of uncontrollable distance between roving strands and single style of siro spinning, and achieve shortened gap, unique style, and reduced The effect of wasted manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment, the present invention will be further elaborated:

[0026] The following specific examples of the present invention illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

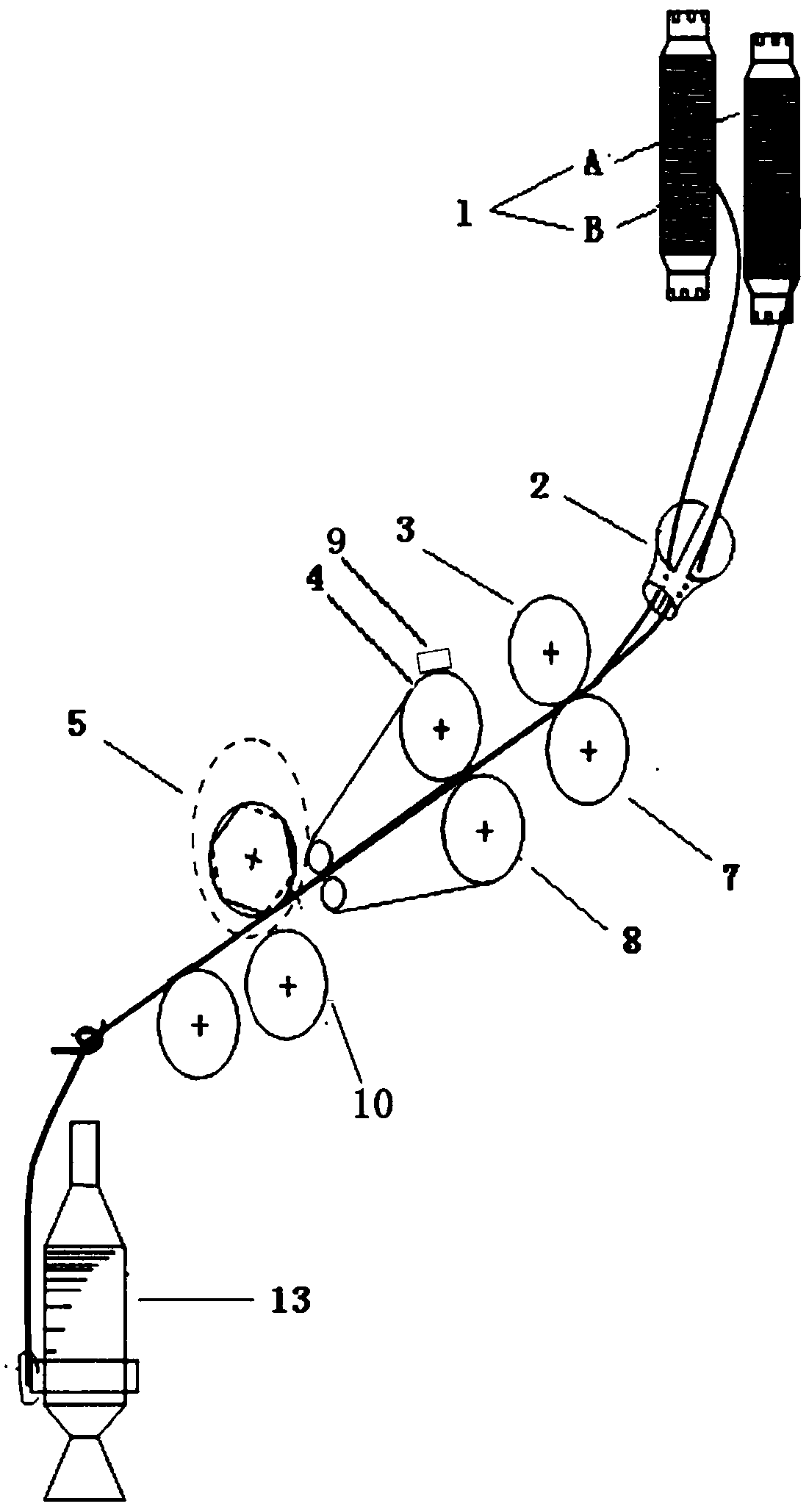

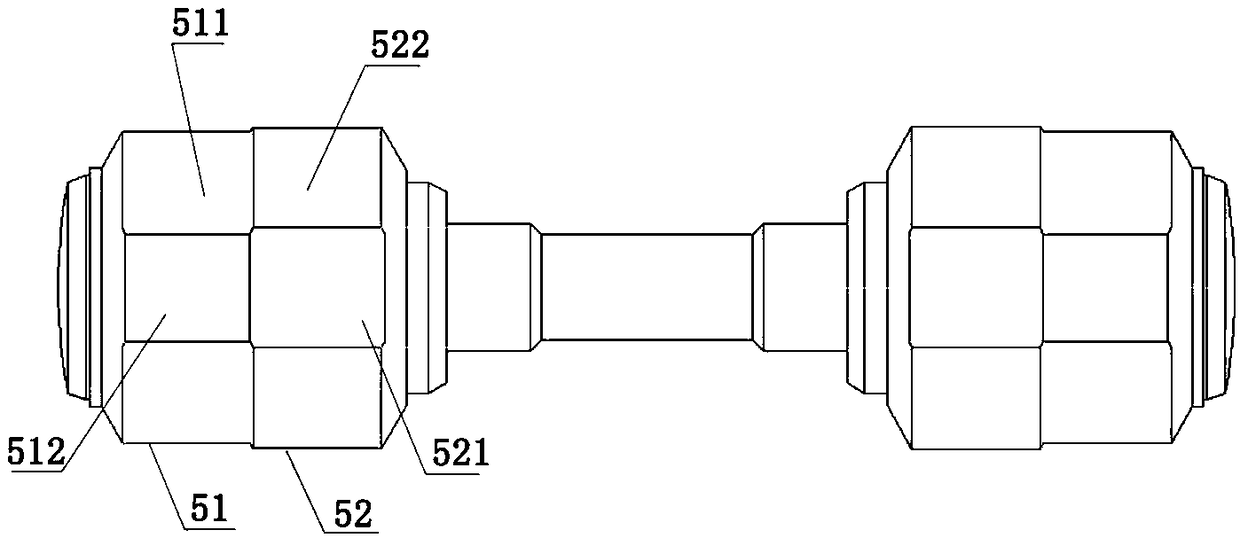

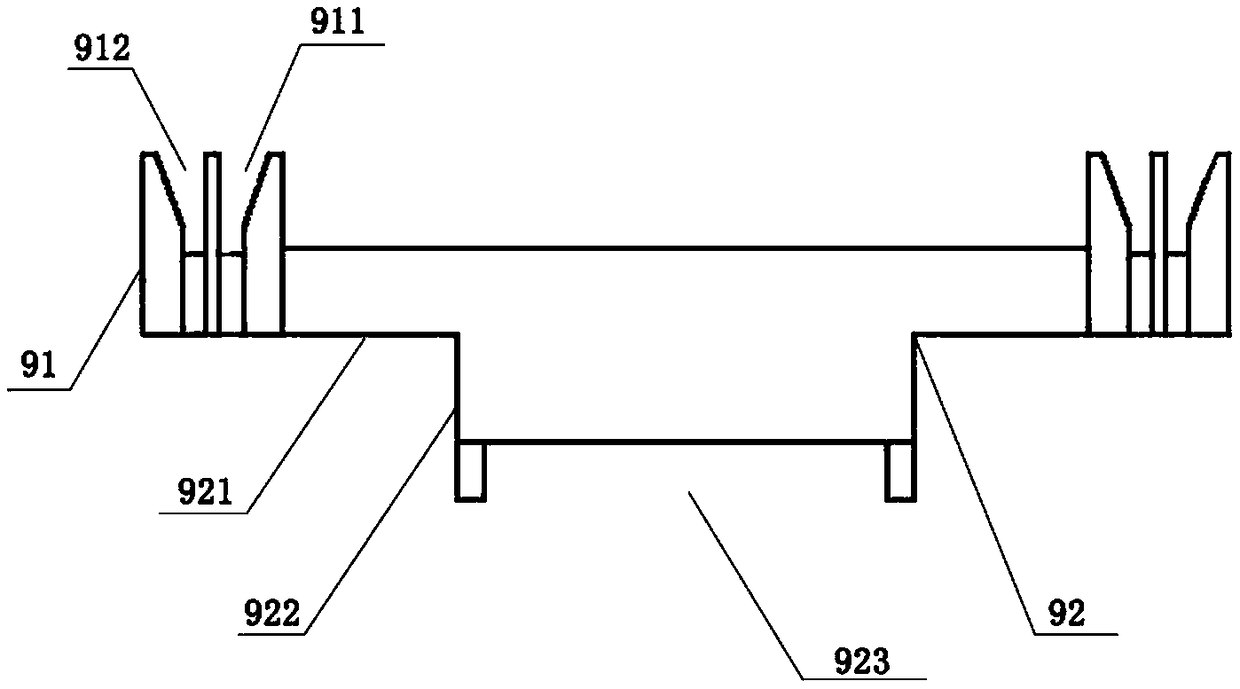

[0027] Such as Figure 1-3 As shown, a novel spinning device of the present invention comprises a siro spinning frame body, and the siro spinning frame body includes a double bell mouth 2, a rear top roller 3, an upper pin 4, a front top roller 5, and a rear top roller. Roller 7, middle roller 8, front roller 10 and spinning bobbin 13, described front top roller 5 comprises the first part 51 and the second part 52 of equal division in axial direction, and described first part 51 is divided into six etc. Faceted, the first part 51 is hexagonal in radial cross-sectional view, and is dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com