Polyurethane prepolymer modified epoxy resin emulsion as well as preparation method and application thereof

A technology of polyurethane prepolymer and epoxy resin emulsion, which is applied in the direction of wear-resistant fibers, textiles and papermaking, fiber types, etc., can solve the problems of reducing the mechanical properties of carbon fibers, increase the degree of curing, increase the surface energy, and improve the fiber cluster effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

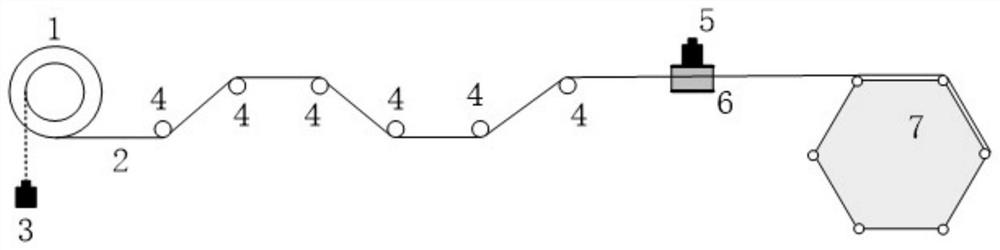

Image

Examples

preparation example Construction

[0050] In one aspect, embodiments of the present invention provides a method for preparing an urethane prepolymer modified epoxy resin emulsion, comprising the following steps:

[0051] Preparation of polyurethane prepolymer step: the metered polyether polyol at a temperature of 110-120 ° C for vacuum stirring dehydration treatment for 60-90min. The temperature is then reduced to 50-60 ° C, to which aliphatic polyisocyanates are added (the purpose of this cooling is to prevent the formation of bursting). Subsequently, the temperature is slowly raised to 90-95 ° C (here, the purpose of heating is to increase the reaction rate of polyols and polyisocyanates), in the nitrogen protection reflux reaction for 2-3h (here, nitrogen protection reflux is: to prevent the reaction of water vapor and isocyanate, affecting the actual reaction effect), to obtain polyurethane prepolymer reaction product (the main component is polyurethane prepolymer).

[0052] Chain expansion, crosslinking steps:...

Embodiment 1-5

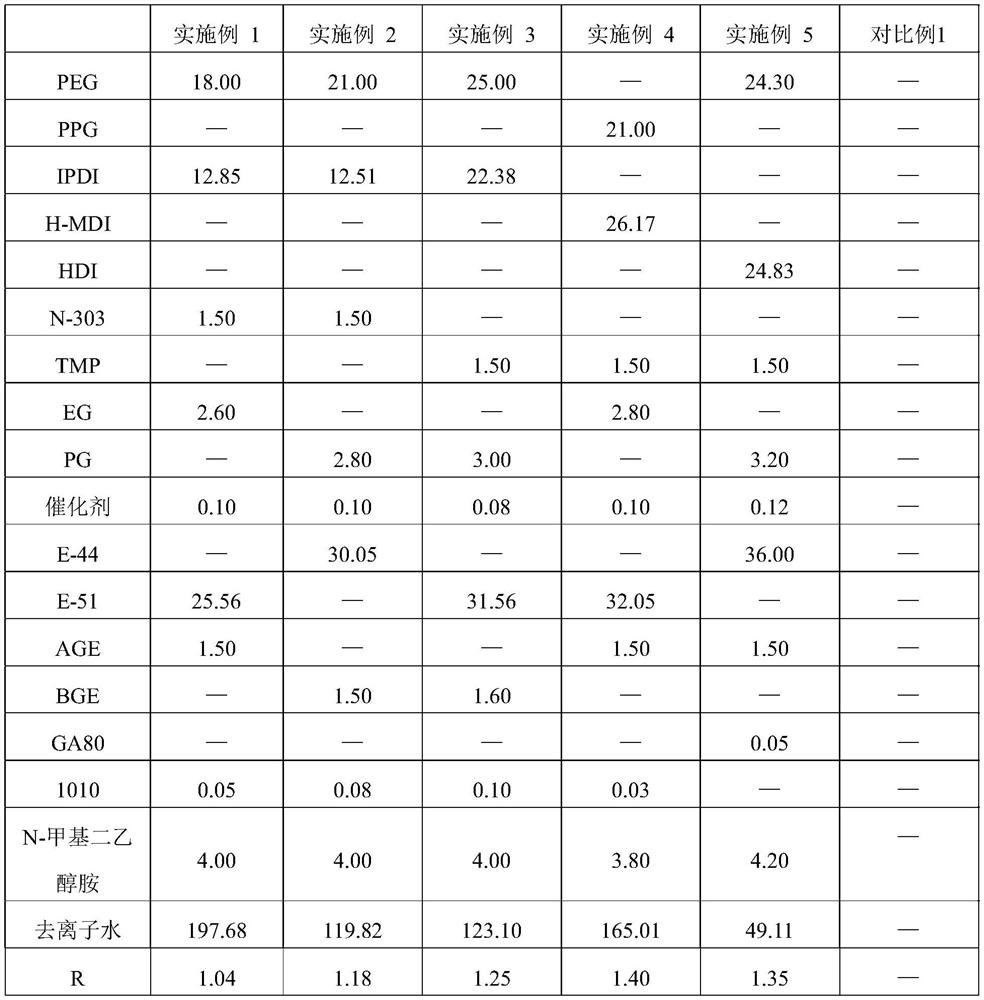

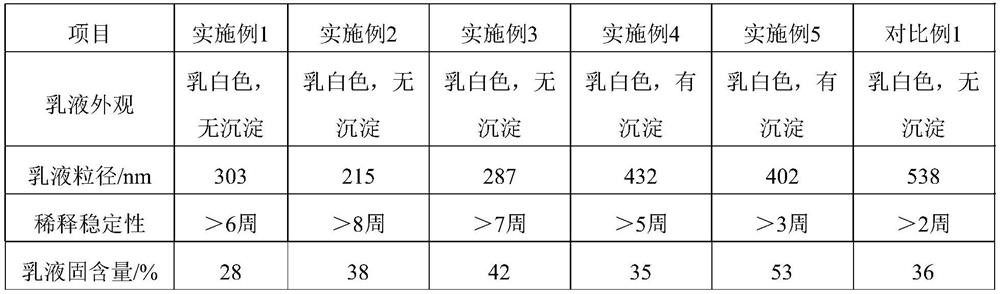

[0080] Examples 1-5 provide a polyurethane prepolymer modified epoxy resin emulsion preparation scheme, specifically each embodiment in accordance with the raw materials in Table 1 (raw material type and portion by weight), the following operation steps:

[0081] Preparation of polyurethane prepolymer step: the metered polyether polyol under a vacuum of 110 ° C, stirred dehydration 60-90min (wherein, Example 1, Example 2 are stirred dehydration for 60min; Example 3, Example 4 are stirred for dehydration for 75min; Example 5 stirred for dehydration for 90min). Then, after reducing the temperature to 50-60 ° C (wherein Examples 1-5 are reduced to 55 ° C), aliphatic polyisocyanates are added to it. Subsequently, the temperature was slowly raised to 90-95 ° C (wherein, Example 1-2 was warmed to 90 ° C, Example 3-4 was heated to 93 ° C, Example 5 was heated to 95 ° C), the reaction under the condition of nitrogen protection reflux was 2-3h, and the polyurethane prepolymer reaction prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com