Impregnating agent for reinforced nylon resin glass fibers and preparation method thereof

A technology of glass fiber and nylon resin, applied in the field of glass fiber sizing for reinforcing nylon resin and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

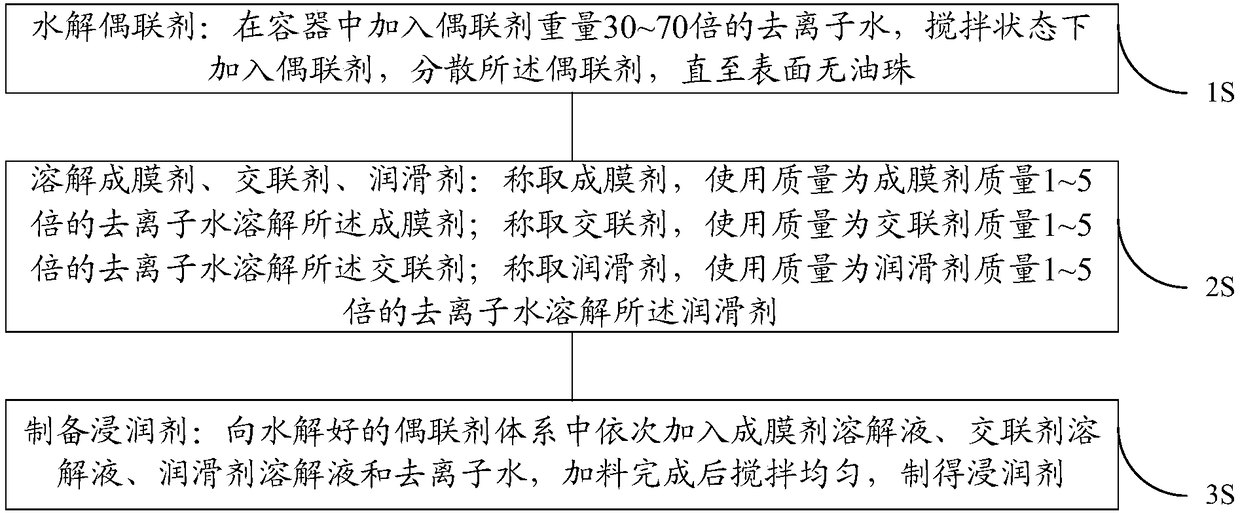

Method used

Image

Examples

Embodiment 1

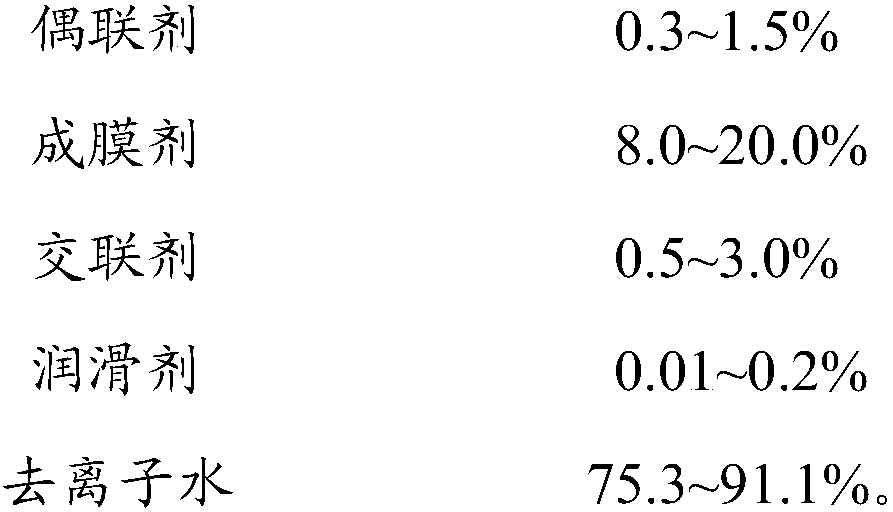

[0059] Weigh each component according to mass percentage, wherein, the coupling agent is γ-aminopropyltriethoxysilane, and the brand used is Momentive A-1100; the film-forming agent A is Chemtura Co., Ltd. 296; film-forming agent B is NEOXIL PS 0151 provided by DSM; cross-linking agent is Heloxy48 from Hexion; lubricant A is polyethylene glycol 600 monooleate, produced by Jiangsu Haitian Petrochemical Company, brand PEG600MO; lubricant B is octadecyltrimethylammonium chloride, produced by Shandong Nuoke Chemical Industry Co., Ltd., brand name Banghua 1831.

[0060] The above-mentioned components are prepared according to the following steps:

[0061] 1S hydrolysis coupling agent: Add deionized water 50 times the weight of the coupling agent into a clean container, slowly add A-1100 under stirring, and disperse until there are no oil droplets on the surface, the time is not less than 20 minutes;

[0062] 2S dissolve film-forming agent, cross-linking agent, lubricant: Weigh fil...

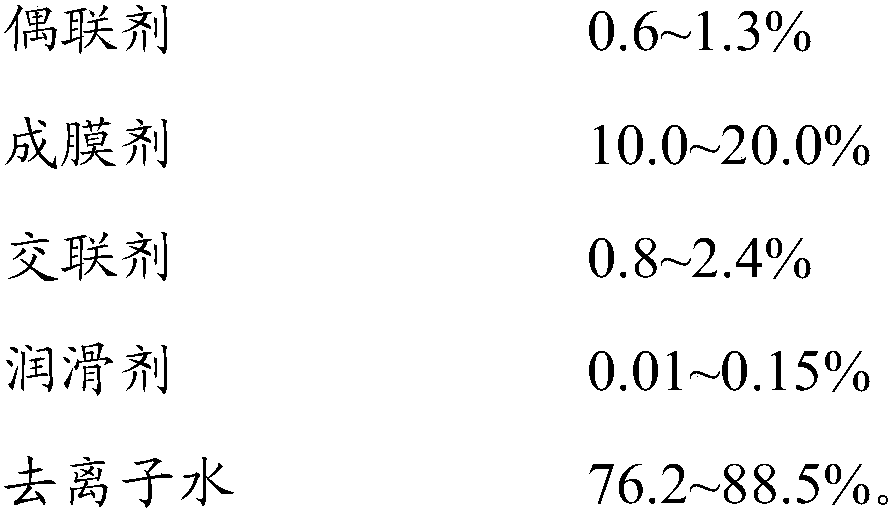

Embodiment 2

[0065] Weigh each component by mass percentage, wherein the coupling agent is a mixture of equal amounts of γ-aminopropyltriethoxysilane and γ-glycidyl etheroxypropyltrimethoxysilane, γ-glycidyl etheroxy Propyltrimethoxysilane is Momentive's A187; lubricant B is a mixture of equal amounts of octadecyltrimethylammonium chloride and cetyltrimethylammonium bromide, cetyltrimethylammonium Ammonium bromide is a product of Shanghai Jinshan Jingwei Chemical Co., Ltd., and the selection of other components is consistent with that of Example 1.

[0066] The above-mentioned components are prepared according to the following steps:

[0067] 1S hydrolysis coupling agent: Add deionized water 70 times the weight of the coupling agent into a clean container, slowly add γ-aminopropyltriethoxysilane and γ-glycidyl etheroxypropyl trimethyl in a stirring state Oxysilane, routinely dispersed until there are no oil beads on the surface, the time is not less than 20 minutes;

[0068] 2S dissolve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com