Method for testing internal moisture of high-frequency baked glass fiber yarns

A technology of glass fiber yarn and testing method, which is applied in the direction of removing certain component weighing, measuring devices, and analyzing materials to achieve the effects of less hairiness, improved product quality and output, and fast baking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

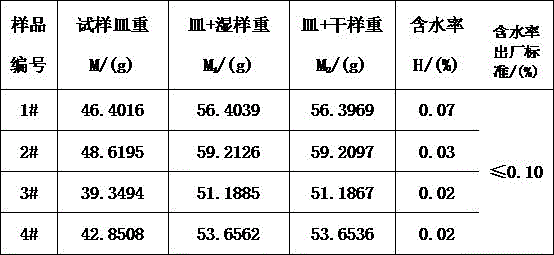

Embodiment 1

[0025] Test sample: glass fiber direct roving;

[0026] Test conditions: temperature 23°C, humidity 60%.

[0027] The test method steps are:

[0028] (1) Select the yarn ball to be sampled: select a good-looking glass fiber yarn ball at the exit of the high-frequency oven, and use a signature pen to mark the end face of the yarn ball in contact with the yarn support plate. The shape of the mark is the same as the yarn ball For the straight lines whose diameters are basically coincident, pack the yarn balls with heat shrink bags and take them off from the creel, and send them to the winding area to adjust the temperature.

[0029] (2) Removal of yarn from the outer ring of the yarn ball to be sampled: place the yarn ball adjusted to room temperature on the creel, remove the heat shrinkable bag, and mark the end surface 1cm away from the outer ring of the yarn ball with a signature pen. Begin to remove the outer ring yarn with the winder until the 1cm mark on the end face.

...

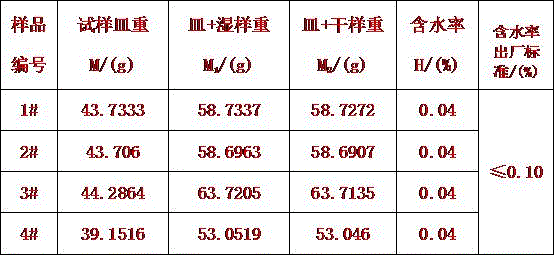

Embodiment 2

[0037] Test sample: glass fiber direct roving;

[0038] Test conditions: temperature 25°C, humidity 60%.

[0039] The test method steps are:

[0040] (1) Select the yarn ball to be sampled: select a good-looking glass fiber yarn ball at the exit of the high-frequency oven, and use a signature pen to mark the end face of the yarn ball in contact with the yarn support plate. The shape of the mark is the same as the yarn ball For the straight lines whose diameters are basically coincident, pack the yarn balls with heat shrink bags and take them off from the creel, and send them to the winding area to adjust the temperature.

[0041] (2) Removal of yarn from the outer ring of the yarn ball to be sampled: place the yarn ball adjusted to room temperature on the creel, remove the heat shrinkable bag, and mark the end surface 1cm away from the outer ring of the yarn ball with a signature pen. Begin to remove the outer ring yarn with the winder until the 1cm mark on the end face.

...

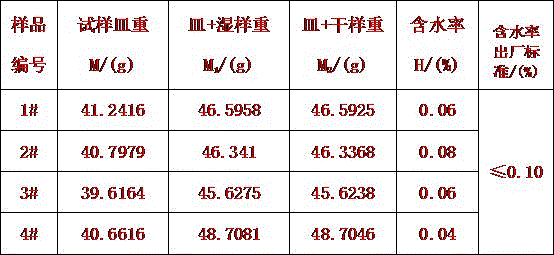

Embodiment 3

[0049] Test sample: glass fiber direct roving;

[0050] Test conditions: temperature 25°C, humidity 70%.

[0051] The test method steps are:

[0052] (1) Select the yarn ball to be sampled: select a good-looking glass fiber yarn ball at the exit of the high-frequency oven, and use a signature pen to mark the end face of the yarn ball in contact with the yarn support plate. The shape of the mark is the same as the yarn ball For the straight lines whose diameters are basically coincident, pack the yarn balls with heat shrink bags and take them off from the creel, and send them to the winding area to adjust the temperature.

[0053] (2) Removal of yarn from the outer ring of the yarn ball to be sampled: place the yarn ball adjusted to room temperature on the creel, remove the heat shrinkable bag, and mark the end surface 1cm away from the outer ring of the yarn ball with a signature pen. Begin to remove the outer ring yarn with the winder until the 1cm mark on the end face.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com