Treatment method of inactivated rhodium-phosphine catalyst

The technology of a rhodium-phosphine catalyst and a treatment method is applied in the field of treatment of deactivated or partially deactivated rhodium-phosphine catalysts in carbonylation reactions, and achieves the effects of improving catalyst activity, low treatment costs, and easing reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

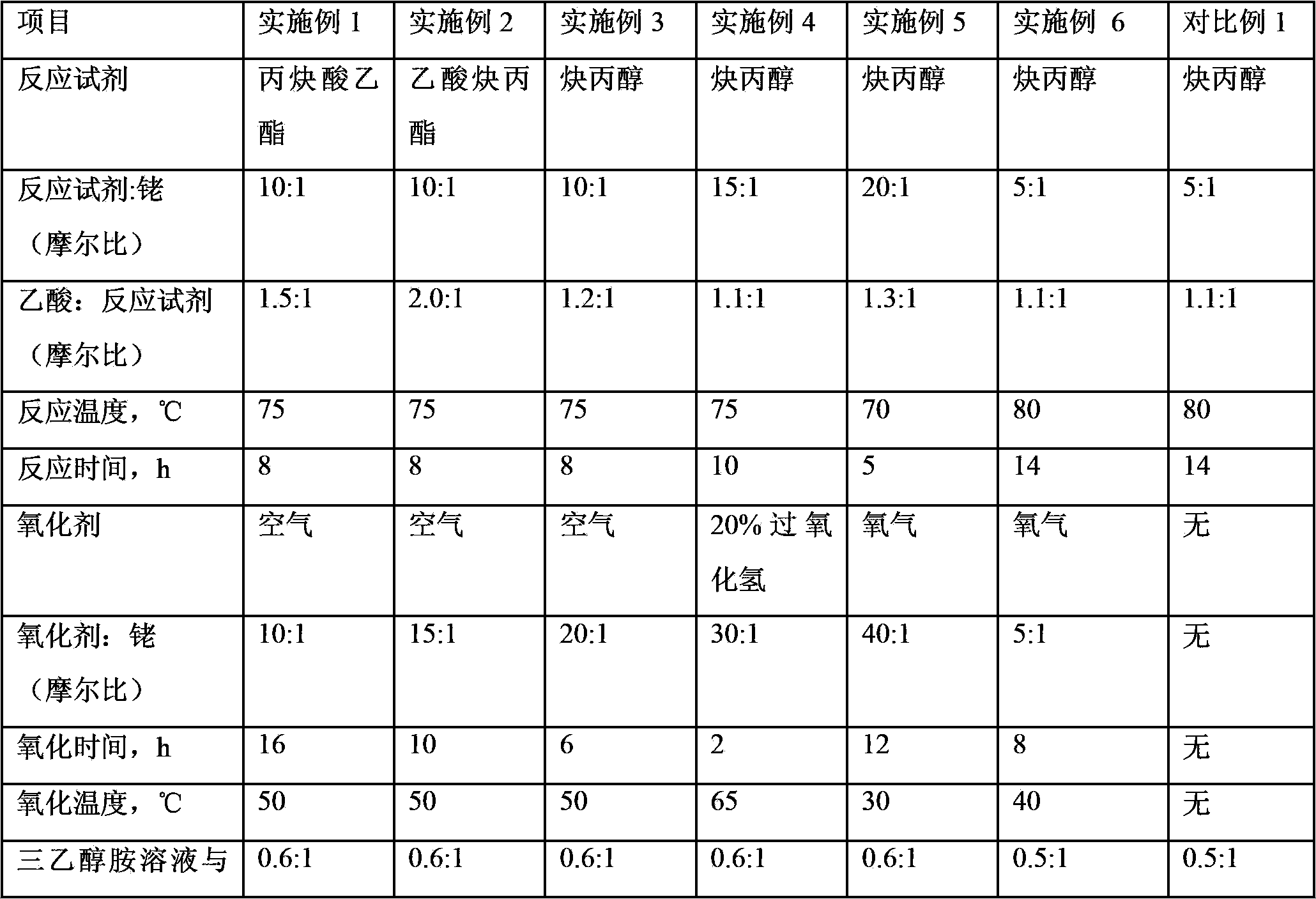

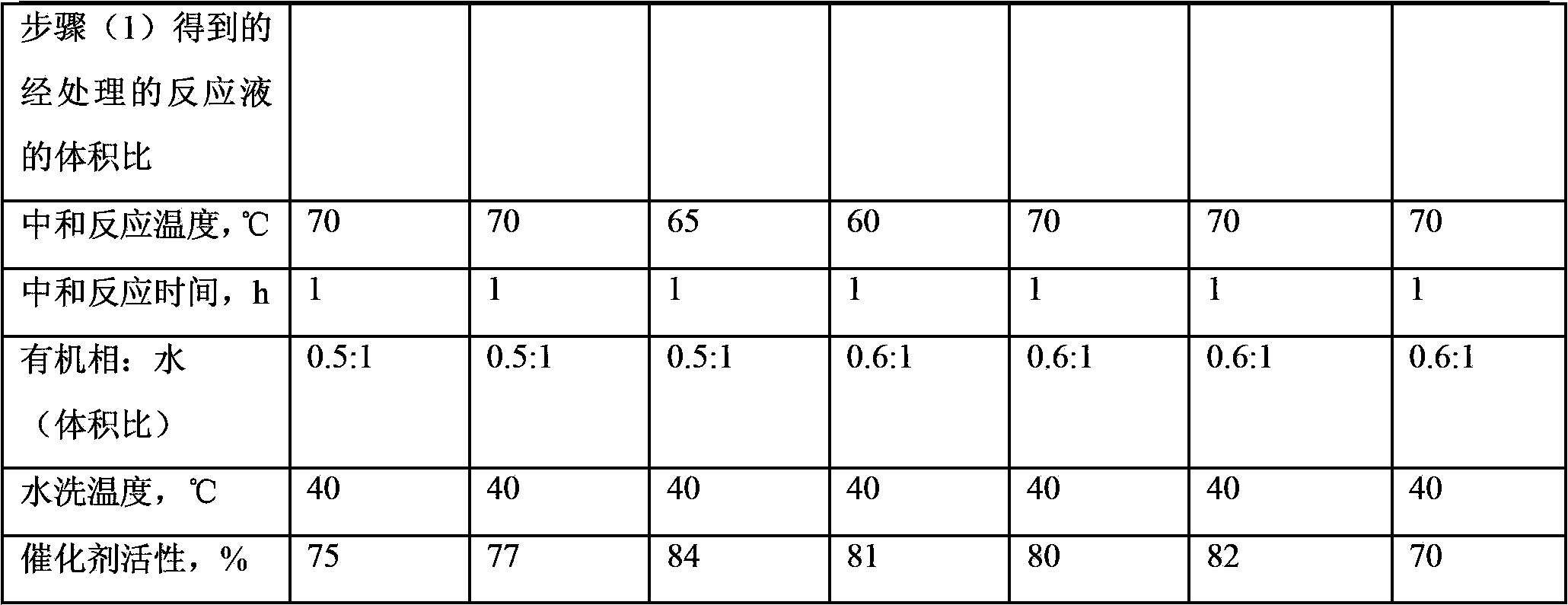

Embodiment 1~6 and comparative example 1

[0036] In the butyraldehyde reaction solution produced by the industrial butyraldehyde plant, the rhodium catalyst activity has been reduced from 100% to 18% of the fresh catalyst. After removing part of butyraldehyde, the rhodium content is about 1050 mg / kg, and the triphenylphosphine content is about 11%. Add 50 g of the reaction solution containing the deactivated rhodium phosphine catalyst into a 100 ml reactor, purge the reactor with nitrogen, and then add alkynols or esters and carboxylic acids containing 3 to 6 carbon atoms as shown in Table 1 Carry out a chemical activation reaction, and after the reaction is completed, an oxidant is introduced into the reactor to further activate the catalyst, and then a 10% triethanolamine aqueous solution is added to neutralize the unreacted carboxylic acid or halide to generate a water-soluble salt.

[0037] After the neutralization reaction is completed, static sedimentation becomes two distinct liquid phases, and the brine-contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com