Method for preparing enol by semi-hydrogenating alkynol

A technology for semi-hydrogenation and alkynol, which is used in hydrogenation preparation, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., and can solve the problems of difficult control of hydrogenation steps and imprecise control of reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

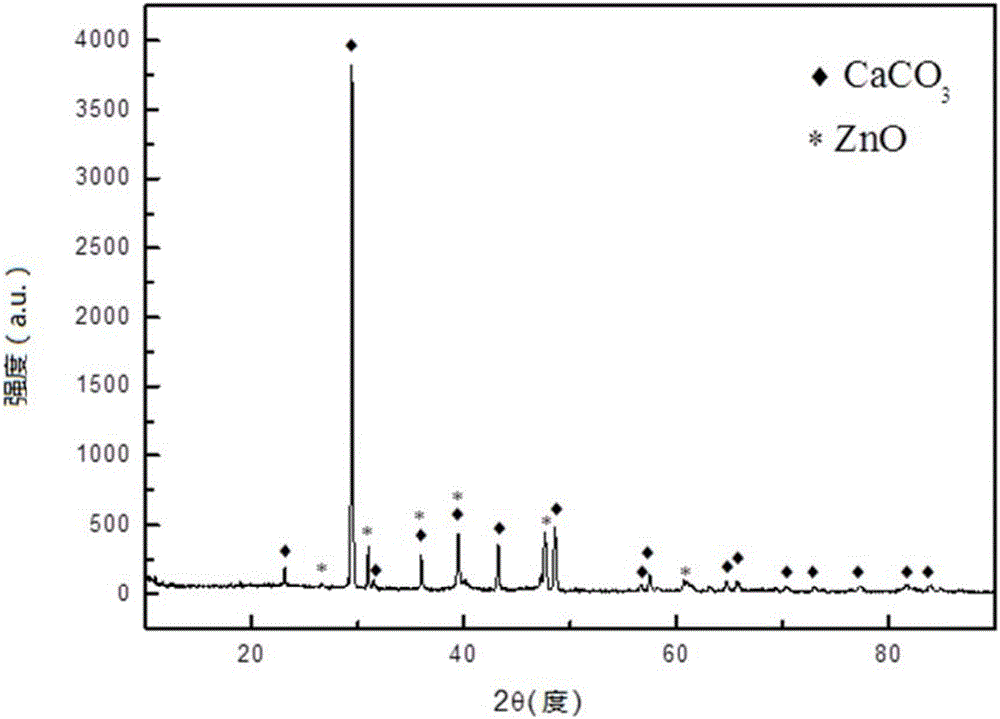

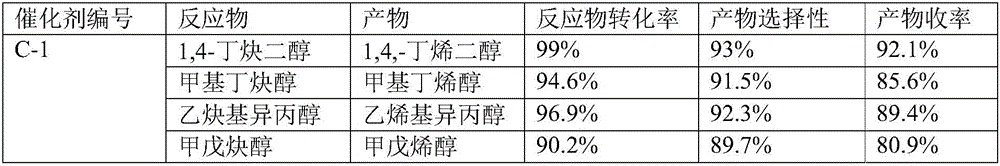

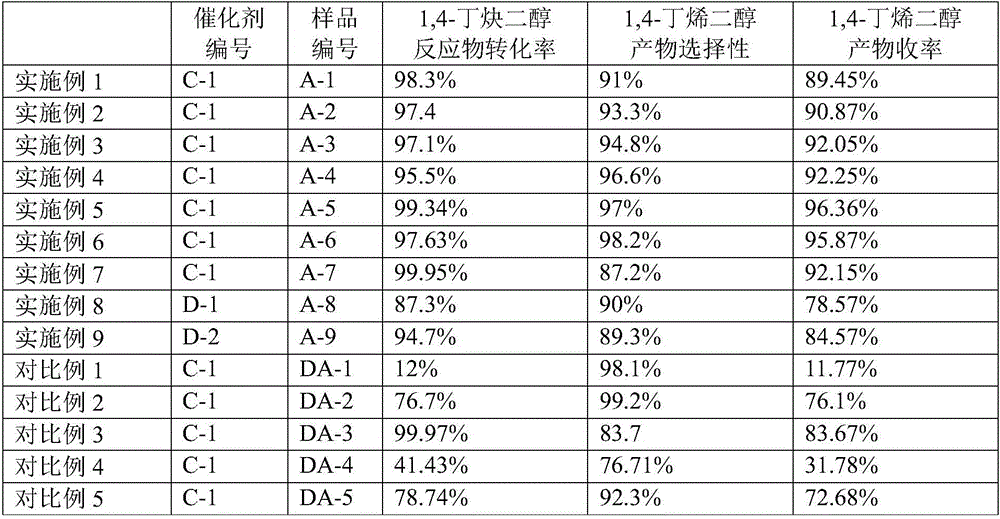

[0073]Add 400mL of concentrated hydrochloric acid with a concentration of 37% to 0.45kg of palladium chloride powder and heat to 60°C to dissolve to form solution A; add 10L of deionized water to 5kg of calcium carbonate with a particle size of 200 mesh and stir for 30min to form a milky white milky cloud Solution B; Dissolve 375g of anhydrous sodium carbonate with 7.5L of deionized water at room temperature and slowly add 305mL of formic acid dropwise until no gas is released (at this time the temperature is about 60°C) to form solution C; then add solution A to In emulsion B, after stirring for 5 minutes, heat up to 80°C and keep warm for 10 minutes to obtain brownish-yellow emulsion AB; then quickly add solution C with a temperature of about 60°C to emulsion AB at one time, and heat up to 85°C , then keep warm and stir for 30min until no gas is released, filter while hot, and wash the filter cake 3 times with deionized water until there is no Cl - , dried and weighed to obt...

preparation example 2

[0075] The preparation method of the catalyst was the same as that of the catalyst preparation example 1, except that the auxiliary agent was changed from zinc acetate to 152 g of iron acetate to make catalyst C-2.

preparation example 3

[0077] The preparation method of the catalyst was the same as that of the catalyst preparation example 1, except that the auxiliary agent was changed from zinc acetate to 140 g of magnesium acetate to make catalyst C-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com