A kind of one-component addition type liquid silicone rubber and preparation method thereof

A liquid silicone rubber, addition-type technology, which is applied in the field of one-component addition-type liquid silicone rubber and its preparation, can solve the problems of limited tear resistance of liquid silicone rubber, increasing the amount of filler silica, and increasing the viscosity of the product. , to achieve the effect of increasing concentrated cross-linking points, improving tear strength and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

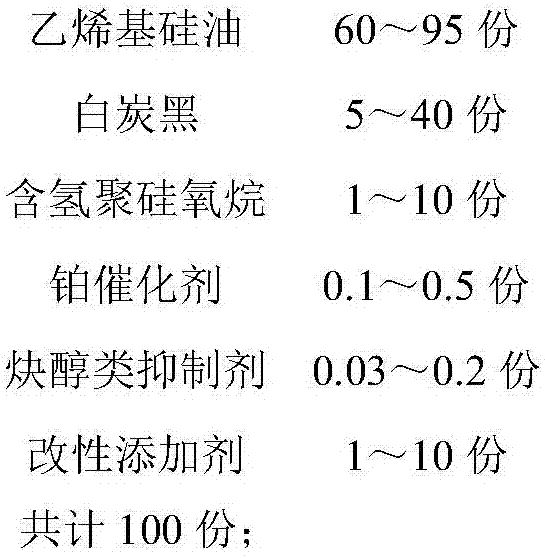

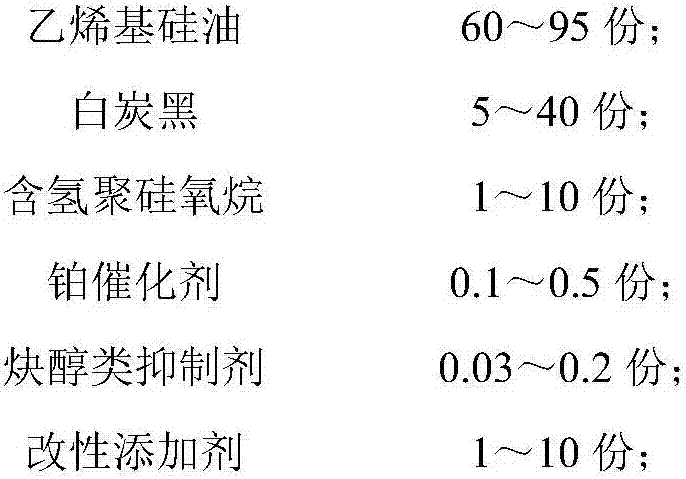

Method used

Image

Examples

Embodiment 1

[0027] Add 70 parts of vinyl polysiloxane with a viscosity of 8000mPa.s into the mixer, then add 20 parts of white carbon black in 6 times, stir for 0.5h after each addition, raise the temperature to 150°C and stir for 2h, then vacuumize Continue to stir for 2 hours, and finally add the remaining 30 parts of vinyl polysiloxane into the blender, and mix evenly to obtain the base glue.

[0028] Take 100 parts of the above-prepared gum base, add hydrogen-containing silicone oil (mass ratio of 0.1% hydrogen-containing terminal polysiloxane and hydrogen-containing 0.7% side hydropolysiloxane) respectively 3 parts of mixture), 0.1 part of platinum catalyst, 0.05 part of acetylenic alcohol inhibitor and 3 parts of modifying additive with a vinyl content of 2%, stirred evenly, and vacuumized to obtain the one-component addition type liquid silicone rubber.

[0029] Inject the obtained liquid silicone rubber into a mold, mold it at 170°C for 10 minutes, and make a 2mm film. Test the te...

Embodiment 2

[0031] Add 80 parts of vinyl polysiloxane with a viscosity of 16000mPa.s into the mixer, then add 25 parts of white carbon black in 6 times, stir for 0.5h after each addition, heat up to 160°C and stir for 2h, then vacuumize Continue to stir for 2 hours, and finally add the remaining 20 parts of vinyl polysiloxane into the blender, and mix evenly to obtain the base glue.

[0032] Take 100 parts of the above-prepared gum base, add hydrogen-containing silicone oil (mass ratio of 0.1% hydrogen-containing terminal hydropolysiloxane and hydrogen-containing 0.7% side-hydrogen polysiloxane) respectively 4 parts of mixture), 0.2 parts of platinum catalyst, 0.07 parts of acetylenic alcohol inhibitor and 5 parts of modifying additive with a vinyl content of 4%, stirred evenly, and vacuumized to obtain the one-component addition type liquid silicone rubber. The test method is the same as in Example 1, and the test results are shown in Table 1.

Embodiment 3

[0034] Add 90 parts of vinyl polysiloxane with a viscosity of 20000mPa.s into the planetary mixer, then add 30 parts of white carbon black in 6 times, stir for 0.5h after each addition, raise the temperature to 170°C and stir for 2h, then pump Continue to stir in vacuum for 2 hours, and finally add the remaining 10 parts of vinyl polysiloxane into the planetary mixer, and mix well to obtain the base glue.

[0035] Take 100 parts of the base gum prepared above, add hydrogen-containing silicone oil (mass ratio is 3:1 of 0.1% hydrogen-containing terminal hydropolysiloxane and hydrogen-containing 0.7% side-hydrogen polysiloxane) 5 parts of mixture), 0.3 parts of platinum catalyst, 0.09 parts of acetylenic alcohol inhibitor and 7 parts of modification additive with vinyl content of 6%, stirred evenly, and vacuumized to obtain the one-component addition type liquid silicone rubber. The test method is the same as in Example 1, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com