Completely degraded starch/PVA (Polyvinyl Alcohol) plastic fishing bait and processing method thereof

A fully degradable, starch-based technology, applied in artificial fish bait, fishing, animal husbandry, etc., can solve problems such as water body environmental pollution, achieve improved mechanical properties, excellent speed-controlling water solubility and biodegradability, and avoid environmental refractory degradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

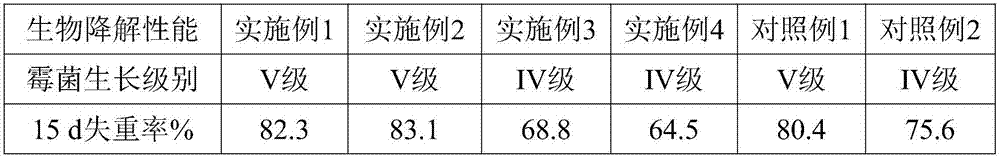

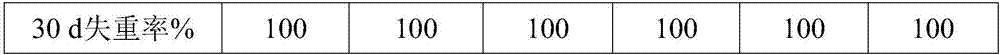

Examples

Embodiment 1

[0031] (1) Add 30kg of plant starch, 15kg of polyvinyl alcohol and 0.5kg of crosslinking agent to the high-speed mixer, heat up to 115-120°C and mix for 10 minutes, then add 2kg of environmentally friendly plasticizer, 0.05kg of hydrolyzed polymaleic anhydride and 0.05 kg hexamethylolmelamine hexamethyl ether, continue to mix at 115-120°C for 5 minutes to obtain the blending main ingredient;

[0032] (2) Add 3kg fly ash, 2kg zeolite powder and 0.5kg ceramic micropowder in the high-speed mixer, and spray water to adjust the water content of the mixed powder to reach 70-75%, mix at room temperature for 5min, then let stand for 30min, then Heat up to 105-110°C and mix for 10 minutes to obtain the blended auxiliary material;

[0033] (3) Add blending main ingredients, blending auxiliary materials, 3kg biodegradable additives and 2kg anionic polyacrylamide into the mixer, melt and knead for 5min, then add the obtained mixture into a twin-screw extruder, and extrude After cooling, ...

Embodiment 2

[0039] (1) Add 30kg of plant starch, 20kg of polyvinyl alcohol and 0.5kg of cross-linking agent to the high-speed mixer, heat up to 115-120°C and mix for 10 minutes, then add 3kg of environmentally friendly plasticizer, 0.1kg of hydrolyzed polymaleic anhydride and 0.05 kg hexamethylolmelamine hexamethyl ether, continue to mix at 115-120°C for 5 minutes to obtain the blending main ingredient;

[0040](2) Add 5kg fly ash, 1kg zeolite powder and 0.5kg ceramic micropowder in the high-speed mixer, and spray water to adjust the water content of the mixed powder to reach 70-75%, mix at room temperature for 5min, then let stand for 30min, then Heat up to 105-110°C and mix for 10 minutes to obtain the blended auxiliary material;

[0041] (3) Add main blending materials, blending auxiliary materials, 5kg biodegradable additives and 1kg anionic polyacrylamide into the mixer, melt and knead for 5min, then add the obtained mixture into a twin-screw extruder, and extrude After cooling, dry...

Embodiment 3

[0047] (1) Add 30kg of plant starch, 20kg of polyvinyl alcohol and 0.5kg of cross-linking agent to the high-speed mixer, heat up to 115-120°C and mix for 10 minutes, then add 3kg of environmentally friendly plasticizer, 0.1kg of hydrolyzed polymaleic anhydride and 0.05 kg hexamethylolmelamine hexamethyl ether, continue to mix at 115-120°C for 5 minutes to obtain the blending main ingredient;

[0048] (2) Add 5kg fly ash, 1kg zeolite powder and 0.5kg ceramic micropowder in the high-speed mixer, and spray water to adjust the water content of the mixed powder to reach 70-75%, mix at room temperature for 5min, then let stand for 30min, then Heat up to 105-110°C and mix for 10 minutes to obtain the blended auxiliary material;

[0049] (3) Add main blending materials, blending auxiliary materials, 5kg biodegradable additives and 1kg anionic polyacrylamide into the mixer, melt and knead for 5min, then add the obtained mixture into a twin-screw extruder, and extrude After cooling, dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com