Wrinkle-removing non-ironing finishing agent for pure cotton clothes and non-ironing finishing process thereof

A non-iron finishing and clothing technology, applied in fiber treatment, biochemical fiber treatment, abrasion-resistant fibers, etc., can solve the problems of release of formaldehyde, human health damage, poor stability, etc., to improve flexibility, comprehensive quality improvement, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

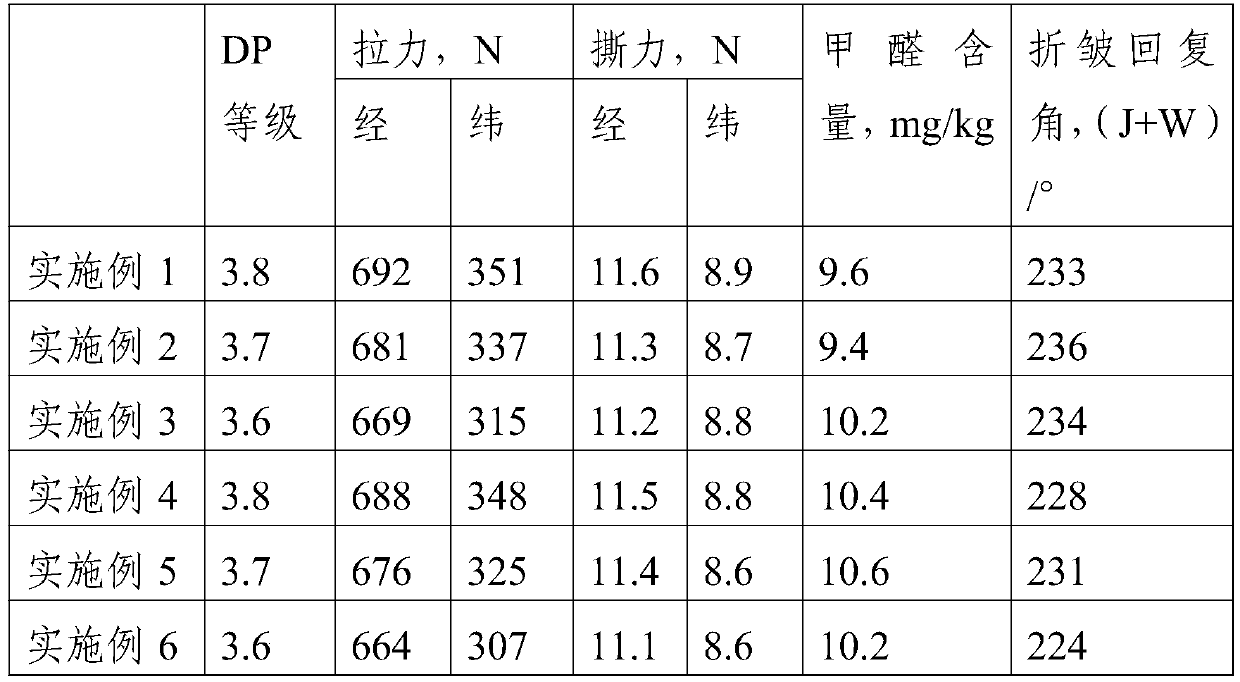

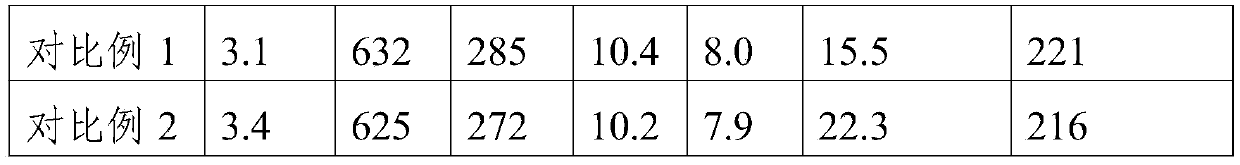

Examples

Embodiment 1

[0025] A wrinkle-free finishing agent for pure cotton clothing, comprising the following components in parts by weight: 120 parts of composite resin base, 30 parts of pure styrene-acrylic emulsion, 25 parts of titanium oxide clay composite material, 10 parts of polyether polyol, polyvinyl alcohol 3 parts of polyamine-type copper-loaded cotton fiber, 15 parts of catalyst, 20 parts of fiber auxiliary agent, and 850 parts of water.

[0026] in,

[0027]The composite resin base is a combination of flexible epoxy resin and phenolic epoxy vinyl ester resin, and the mass ratio of the two is 1:2; the titanium oxide clay composite material includes the following components in mass percentage: nano titanium dioxide 10%, amino clay 6%, polyimide resin 15%, oil cocoamide monoethanolamine 1%, KR-238S 1%, n-isopropylacrylamide 2%, water balance; polyethylene polyamine type copper-loaded cotton fiber Copper load is 10.7mg / g, and described polyethylene polyamine adopts the composition of die...

Embodiment 2

[0034] A wrinkle-free finishing agent for pure cotton clothing, comprising the following components in parts by weight: 120 parts of composite resin base, 30 parts of pure styrene-acrylic emulsion, 30 parts of titanium oxide clay composite material, 10 parts of polyether polyol, polyvinyl alcohol 3 parts of polyamine-type copper-loaded cotton fibers, 20 parts of catalysts, 20 parts of fiber additives, and 850 parts of water.

[0035] in,

[0036] The composite resin base is a combination of flexible epoxy resin and phenolic epoxy vinyl ester resin, and the mass ratio of the two is 1:1; the titanium oxide clay composite material includes the following components in mass percentage: nano titanium dioxide 10%, amino clay 6%, polyimide resin 10%, oil cocoamide monoethanolamine 2%, KR-238S 2%, n-isopropylacrylamide 3%, water balance; polyethylene polyamine type copper-loaded cotton fiber Copper load is 10.3mg / g, and described polyethylene polyamine adopts the composition of diethy...

Embodiment 3

[0043] A wrinkle-free finishing agent for pure cotton garments, comprising the following components in parts by weight: 150 parts of composite resin base, 30 parts of pure styrene-acrylic emulsion, 30 parts of titanium oxide clay composite material, 10 parts of polyether polyol, polyvinyl alcohol 4 parts of polyamine-type copper-loaded cotton fiber, 20 parts of catalyst, 25 parts of fiber auxiliary agent, and 900 parts of water.

[0044] in,

[0045] The composite resin base is a combination of flexible epoxy resin and phenolic epoxy vinyl ester resin, and the mass ratio of the two is 1:1; the titanium oxide clay composite material includes the following components in mass percentage: nano titanium dioxide 12%, amino clay 5%, polyimide resin 10%, oil cocoamide monoethanolamine 1%, KR-238S 1%, n-isopropylacrylamide 4%, water balance; polyethylene polyamine type copper-loaded cotton fiber Copper load is 10.5mg / g, and described polyethylene polyamine adopts the composition of di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com