Synthesis of siloxane containing nitrile group and vinyl group and preparation method of room temperature addition type nitrile silicone rubber

A nitrile-silicone rubber, addition-type technology, applied in the field of organic silicon polymer synthesis, can solve problems such as poor controllability, insufficient heat resistance, and less nitrile-silicone rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

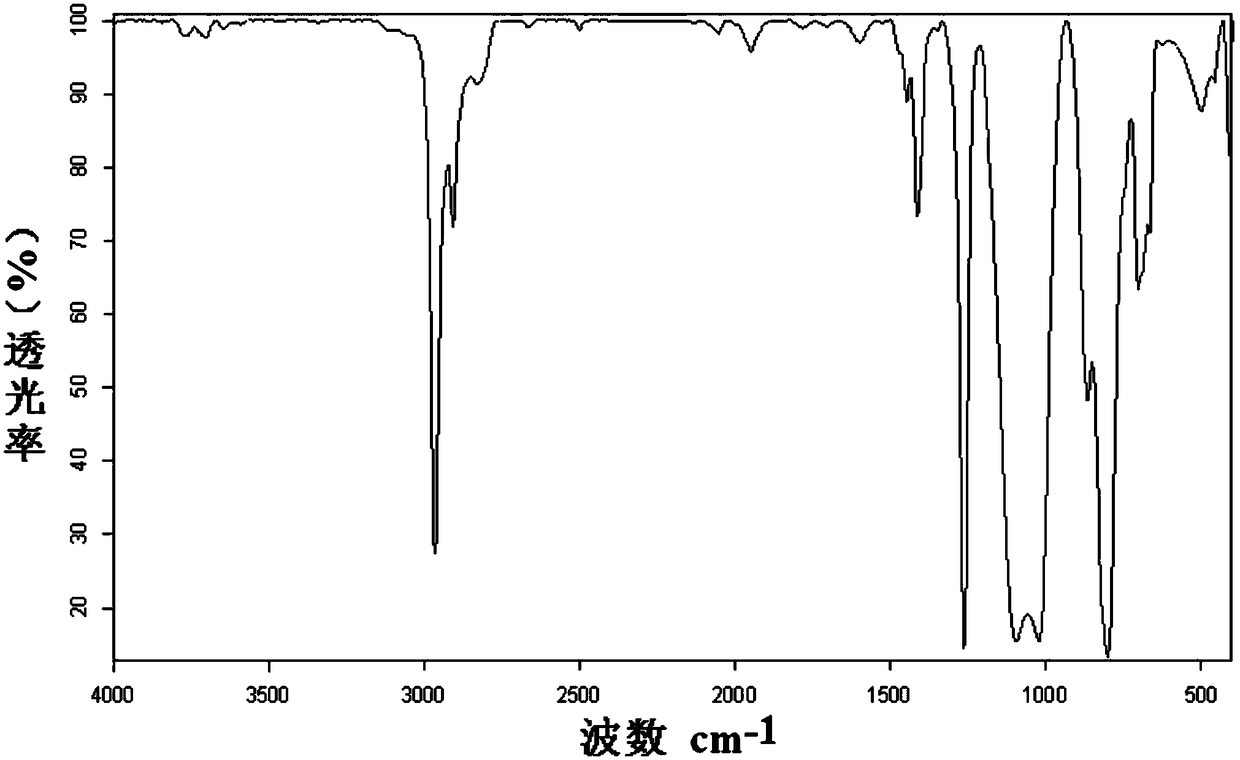

Image

Examples

Embodiment Construction

[0011] Technical scheme of the present invention is as follows:

[0012] A kind of synthetic method of the siloxane containing nitrile group and vinyl simultaneously, comprises steps as follows:

[0013] Mix the siloxane containing amino group and vinyl group with the unsaturated compound containing nitrile group under the condition of using solvent or without solvent, and mix the amino group and unsaturated compound under the condition of using catalyst or without using any catalyst. The reaction between the double bonds in the compound introduces the nitrile group into the siloxane molecule to produce a siloxane containing both nitrile and vinyl groups.

[0014] The present invention contains the synthetic equation of nitrile group and vinyl siloxane simultaneously:

[0015] ≡Si-R'-NH 2 +CH 2 =CH-R″-CN→≡Si-R′-NH-CH 2 CH 2 -R″-CN

[0016] Wherein, R' and R " are various organic groups.

[0017] According to the present invention, preferably, the reaction temperature be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com