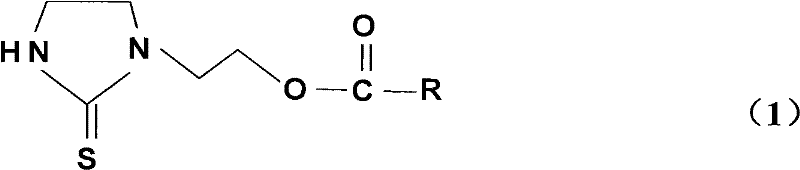

A kind of corrosion inhibitor for suppressing h2s/co2 corrosion and preparation method thereof

A corrosion inhibitor and CO2 technology, which is applied in earthwork drilling, wellbore/well components, etc., can solve the problems of cumbersome preparation, low efficiency and high cost of imidazoline quaternary ammonium compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

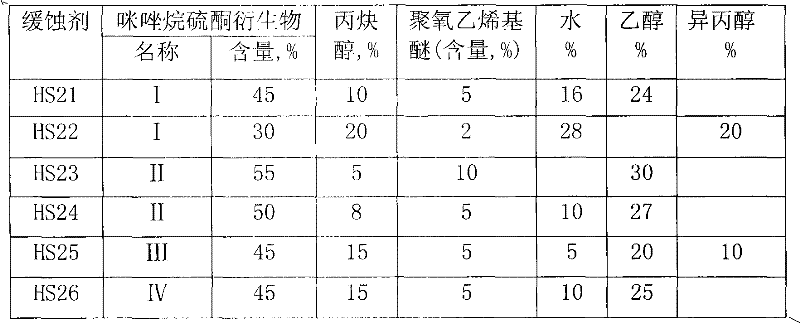

Examples

Embodiment 1

[0026] Mix and stir thiourea and β-hydroxyethylethylenediamine according to the molar ratio of 1:1, heat up to 160°C and react for 4 hours; after cooling below 90°C, add oleic acid according to the molar ratio of 1:0.9 molar ratio of thiourea, After the addition is complete, react at a temperature of 150° C. for 3 hours, and obtain the imidazolidinethione derivative I after cooling.

Embodiment 2

[0028] According to the method similar to the preparation of imidazolidinethione derivative I in Example 1, linoleic acid was used instead of oleic acid to prepare imidazolidinethione derivative II.

Embodiment 3

[0030] Mix and stir thiourea and β-hydroxyethylethylenediamine according to the molar ratio of 1:1.5, heat up to 160°C and react for 4 hours; after cooling below 90°C, add oleic acid according to the molar ratio of 1:1 molar ratio of thiourea, After the addition, the reaction was carried out at 150°C for 3 hours, and the imidazolidinethione derivative III was obtained after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com