Electrochemical treatment system and method for circulating cooling water of gas-steam combined cycle unit

A combined cycle unit and circulating cooling water technology, applied in the field of water treatment, can solve problems such as the difficulty of scale treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

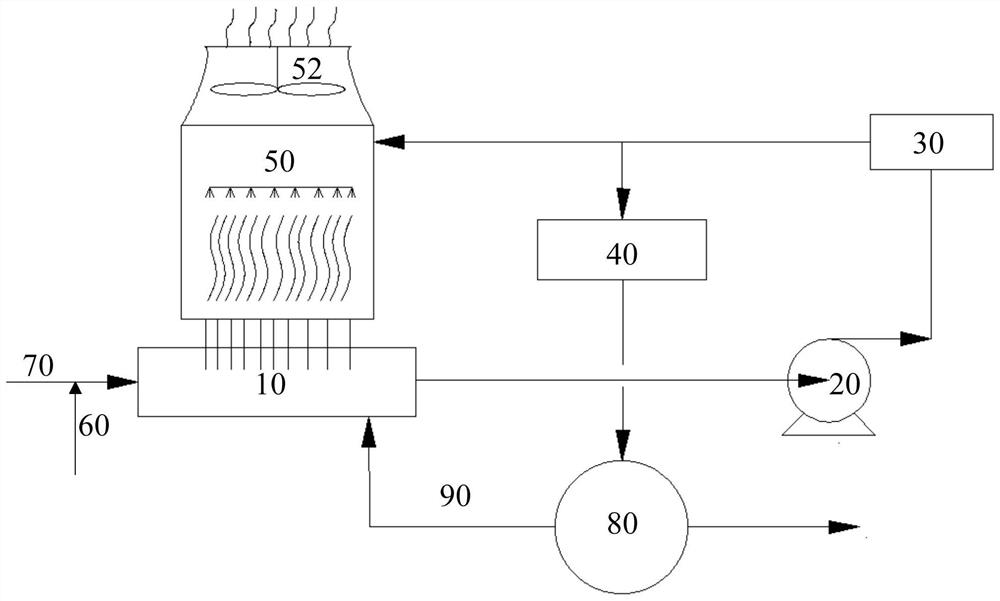

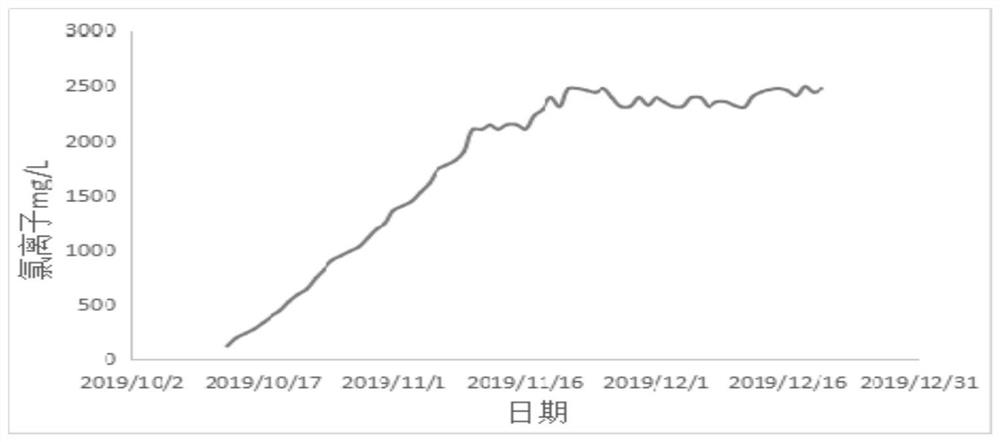

[0079] use figure 1 The equipment is used to treat the circulating cooling water of Beijing Jingxi Gas Thermal Power Co., Ltd. The result is as Figure 2-9 shown.

[0080] from Figure 2-9 It can be seen from the changes in the curves of each parameter that when the circulating water is only supplemented and not discharged during operation, the chloride ions, calcium ions, total hardness and electrical conductivity show an increasing trend with the increase of the test time. When the test lasts for a certain time Afterwards, the chloride ions and the electrical conductivity reach a dynamic balance, fluctuate in a small range and no longer rise. This phenomenon shows that during the operation of the circulating water, the mechanical fan of the cooling tower carries away part of the ions in the process of cooling the circulating water. At the same time, The electrochemical device 40 has obvious removal effects on scale-forming ions and chloride ions, especially the removal ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com