A kind of wear-resistant anticorrosion coating and its preparation method and application

A technology of anti-corrosion coatings and wear-resistant fillers, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of inability to improve the wear resistance of magnesium alloys, poor corrosion resistance, and accelerated corrosion of magnesium alloys. Achieve the effects of avoiding electrochemical potential difference, good storage stability, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

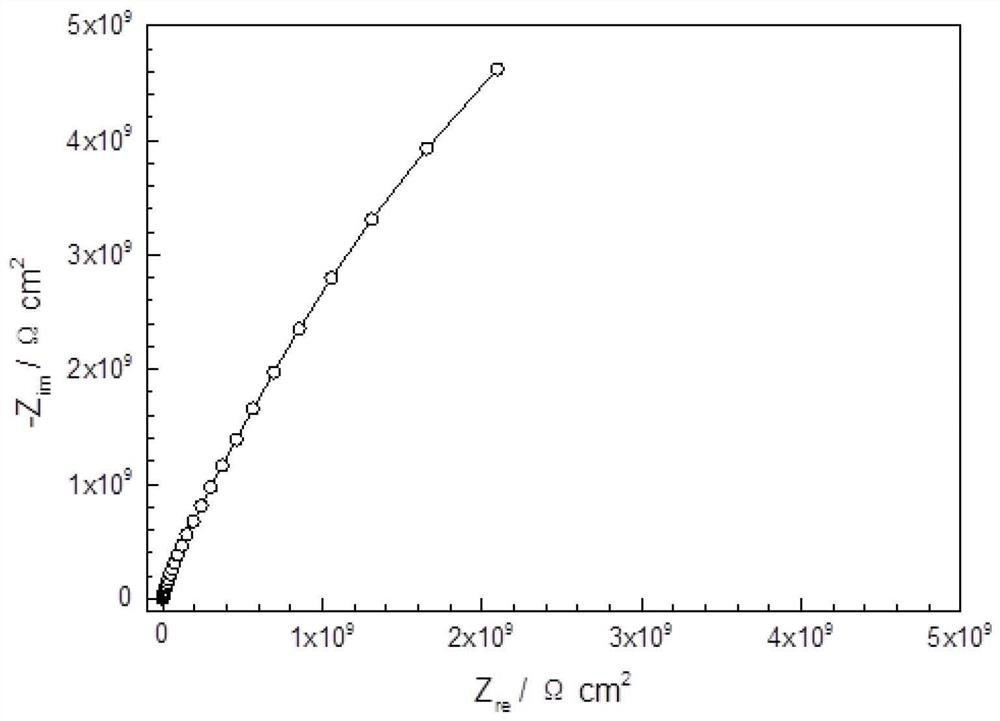

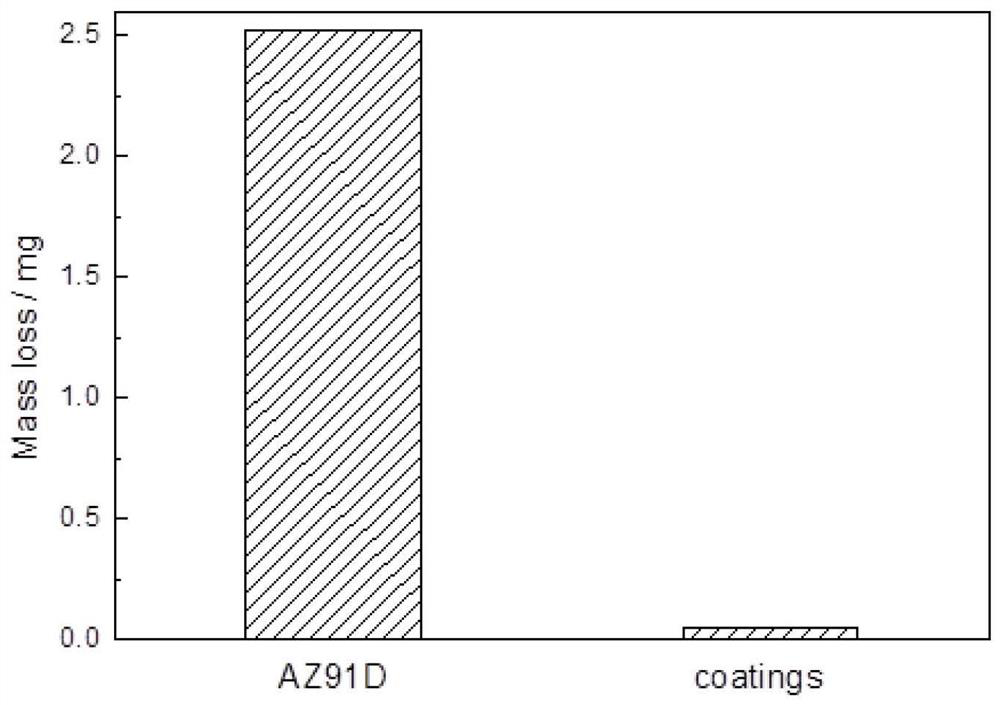

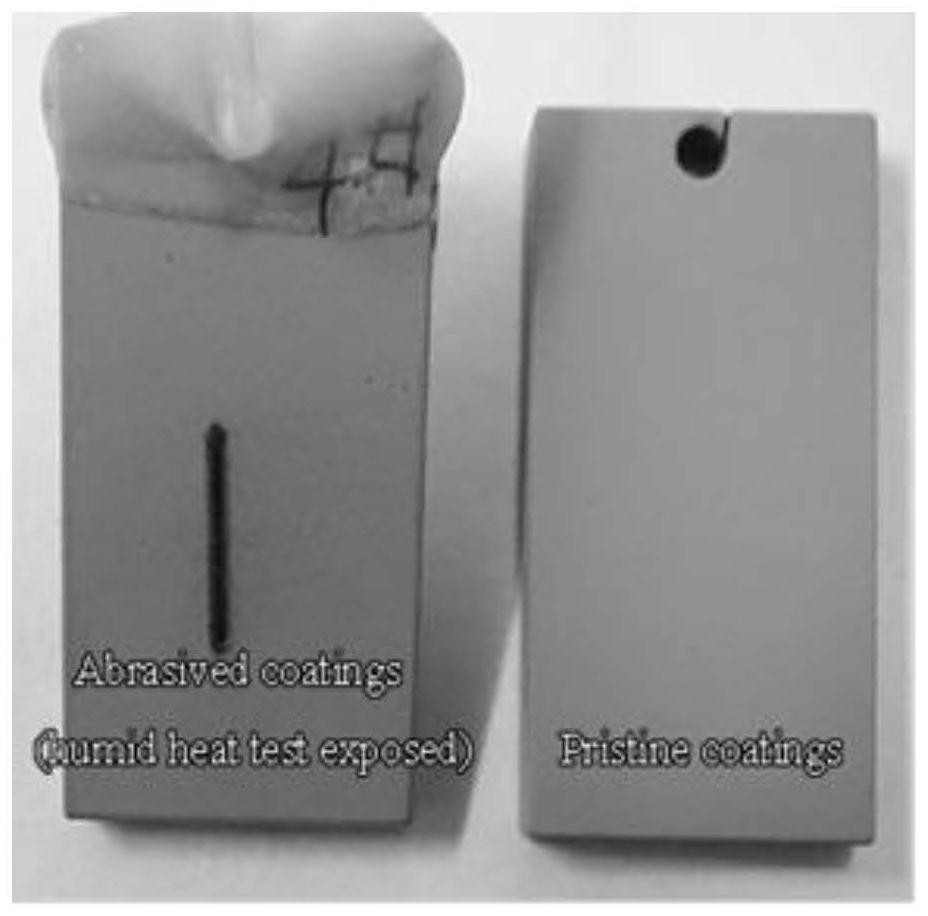

Image

Examples

Embodiment 1

[0048]In this example, 20 parts of silicon nitride powder with a particle size of 10 μm, 0.8 parts of fumed silica with a particle size of 20 nm, 10 parts of muscovite powder with a particle size of 12 μm, and 0.9 parts of N- Nitrosophenylamine, put into 30 parts of polyurethane resin in turn, then weigh and put into 30 parts of X-10 solvent, stir evenly and put 50 parts of grinding beads with a particle size of 1mm into the paint stirring and dispersing grinder Grind and disperse at 2000rpm for 40 minutes, take it out, and filter it with a 120-mesh stainless steel mesh to obtain component A with a size of 10 to 30 microns. Weigh 15 parts of component B modified alkyd resin curing agent, and mix component A (component A with The mass ratio of component B is 1:1-2) and the wear-resistant and anti-corrosion coating can be obtained after being fully mixed evenly.

[0049] Prepare a wear-resistant and anti-corrosion coating on the surface of the AZ91D magnesium alloy that has been...

Embodiment 2

[0056] In this embodiment, in terms of parts by mass, 30 parts of boron nitride powder with a particle size of 15 μm, 1 part of fumed silica with a particle size of 50 nm, 8 parts of ground calcium carbonate powder with a particle size of 25 μm, and 1.5 parts Hexamethylenetetramine, put into 50 parts of polyurethane resin successively, weigh again and put into 35 parts of xylene, stir evenly and put 60 parts of grinding beads with a particle diameter of 2mm in the paint stirring and dispersing grinder at 3000rpm Grind and disperse at a rotating speed for 30 minutes, take it out, and filter it with a 300-mesh stainless steel mesh to obtain component A of 10 to 30 microns, weigh 25 parts of component B curing agent, and mix component A (the mass ratio of component A to component B is 1:1~ 2) Wear-resistant and anti-corrosion coatings can be obtained after fully mixing evenly.

[0057] Prepare a wear-resistant and anti-corrosion coating on the surface of the AZ31 magnesium alloy ...

Embodiment 3

[0063] In this embodiment, in terms of parts by mass, 10 parts of silicon nitride powder with a particle size of 20 μm, 15 parts of boron nitride powder with a particle size of 15 μm, 1.2 parts of fumed silica with a particle size of 100 nm, and 5 parts of particle size Muscovite powder with a particle size of 2 μm, 7 parts of ground calcium carbonate powder with a particle size of 20 μm, 0.8 part of N-nitrosophenylamine, and 1 part of hexamethylenetetramine were put into 60 parts of polyurethane resin in sequence, and then Weigh and put in 40 parts of X-10 diluent and 40 parts of xylene, stir evenly and put them together with 80 parts of grinding beads with a particle size of 0.5 mm into a paint stirring and dispersing grinder at a speed of 1500 rpm for 60 minutes and take it out with Filter with 120 mesh stainless steel mesh to obtain component A with a size of 10-30 microns, weigh 30 parts of component B curing agent, and fully mix with component A (the mass ratio of compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com