Oil-soluble corrosion inhibitor, its preparation method

An oil-soluble corrosion inhibitor and corrosion inhibitor technology, which is applied in the directions of earthwork drilling, wellbore/well components, etc., can solve the problems of cumbersome preparation of imidazoline quaternary amine compounds, poor corrosion inhibition effect, etc., and achieves simple manufacturing, chemical Good stability and thermal stability, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

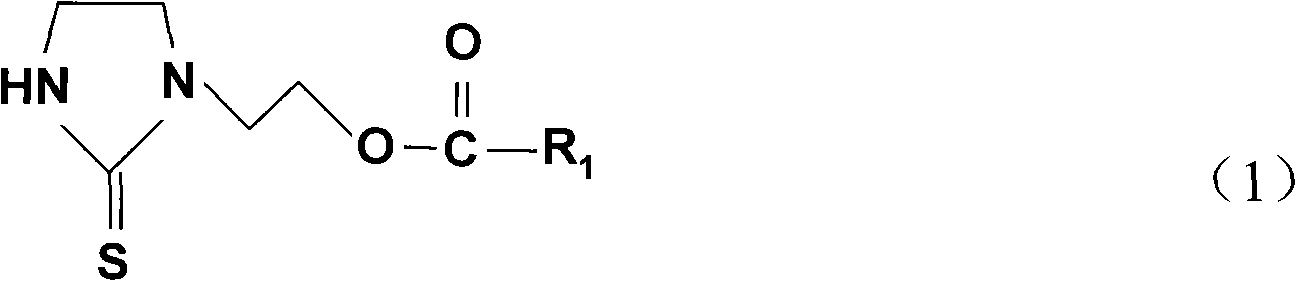

[0027] Mix and stir thiourea and β-hydroxyethylethylenediamine according to the molar ratio of 1:1.2, heat up to 160°C and react for 4 hours; after cooling below 80°C, add according to the molar ratio of 1:1 to thiourea After the addition of isooctanoic acid, react at a temperature of 150°C for 4 hours, and obtain the imidazolidinethione derivative I after cooling.

[0028] Mix and stir thiourea and 3-hydroxyethylethylenediamine according to the molar ratio of 1:1, raise the temperature to 150°C and react for 3 hours; after cooling below 80°C, add lauryl according to the molar ratio of 1:0.8 to thiourea Acid (dodecanoic acid), react at a temperature of 180° C. for 2 hours after the addition, and obtain imidazolidinethione derivative II after cooling.

[0029] Mix and stir thiourea and β-hydroxyethylethylenediamine at a molar ratio of 1:1.1, heat up to 150°C for 3 hours; cool to below 80°C and add positive Octanoic acid, react at a temperature of 180° C. for 2 hours after the ...

Embodiment 2

[0031] Mix and stir n-octanol and phosphorus pentoxide at a molar ratio of 1:1.5, raise the temperature to 50° C., react for 3 hours, and obtain mixed alkyl phosphate IV after cooling.

[0032] Mix and stir n-dodecyl alcohol and phosphorus pentoxide at a molar ratio of 1:1, raise the temperature to 80°C, react for 5 hours, and obtain mixed alkyl phosphate V after cooling.

Embodiment 3

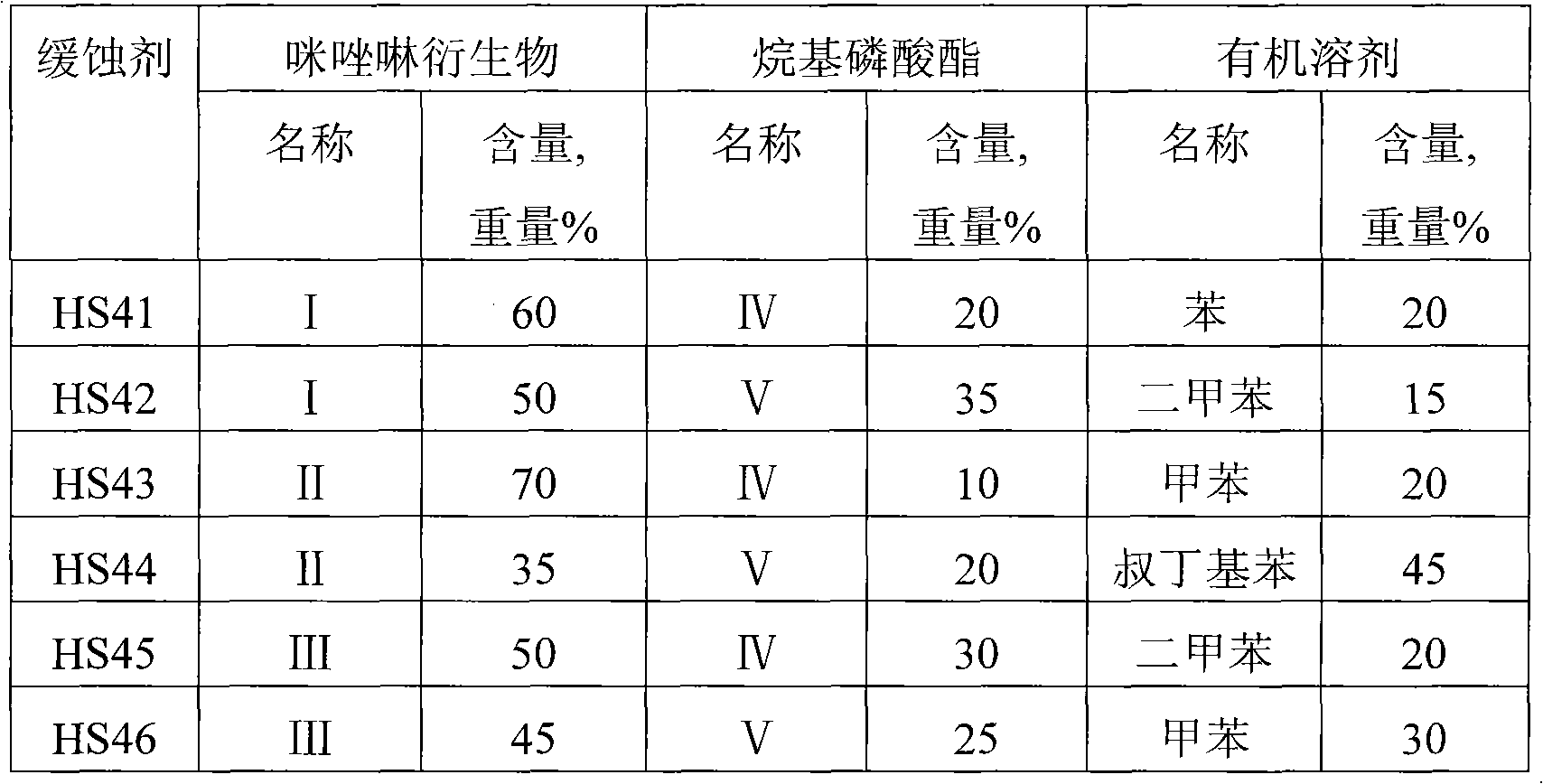

[0034] Obtain imidazolidinethione derivatives I, II, III and mixed alkyl phosphate IV, V respectively with C according to Examples 1-2 6 ~C 10 Aromatics were stirred and mixed according to the weight ratio to prepare different corrosion inhibitors, as shown in Table 1.

[0035] The composition of table 1 corrosion inhibitor

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com