Regeneration method for inactivated rh-p (rhodium-phosphine) complex catalyst for carbonylation reaction

A technology of carbonylation reaction and complexes, which is applied in the field of regeneration of deactivated rhodium-phosphine complex catalysts in carbonylation reactions, to achieve the effects of easy industrialization, reduced dosage, and improved catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

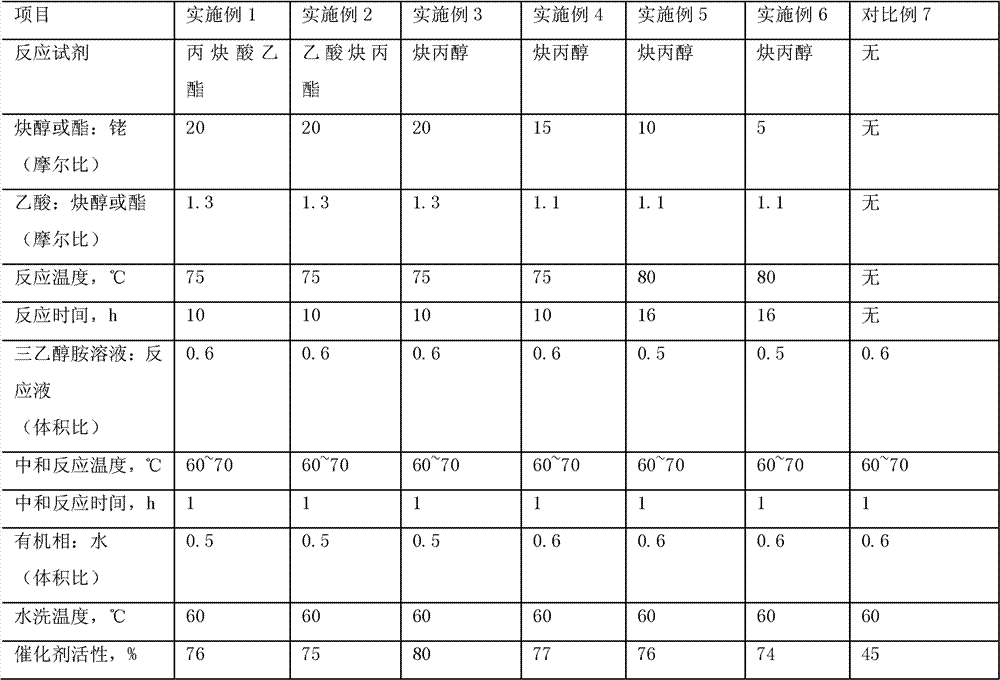

Embodiment 1~6 and comparative example 7

[0035] In the butyraldehyde reaction liquid produced by the industrial butanol unit, the activity of the rhodium catalyst has been reduced from 100% to about 25% of the fresh catalyst. After removing part of the butyraldehyde, the rhodium content is about 1100mg / kg, and the triphenylphosphine content is about 10%. . Add 50 g of the reaction solution containing the partially deactivated catalyst into a 100 ml reactor, purging the reactor with nitrogen, and then adding acetylenic alcohols or esters containing 3 to 6 carbon atoms in different proportions as shown in Table 1 React with carboxylic acid, add 10% triethanolamine aqueous solution into the reactor after the reaction, neutralize unreacted carboxylic acid or halide, and generate water-soluble salt.

[0036] After the neutralization reaction is finished, two distinct liquid phases are formed by static settling, which are separated to obtain an organic phase containing an aqueous phase and a rhodium complex catalyst. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com