One-component, solvent-free organosiloxane composition

A technology of organosiloxane and polyorganosiloxane, which is applied in the direction of surface coating liquid devices, printed circuits, coatings, etc., and can solve problems such as uneven layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

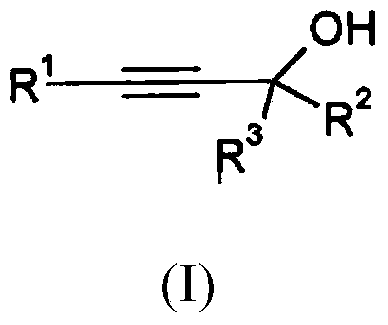

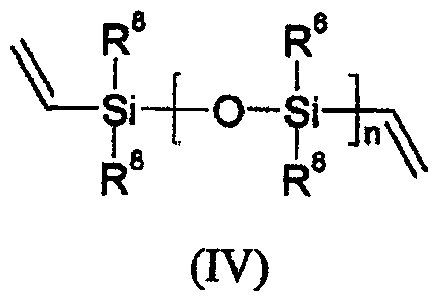

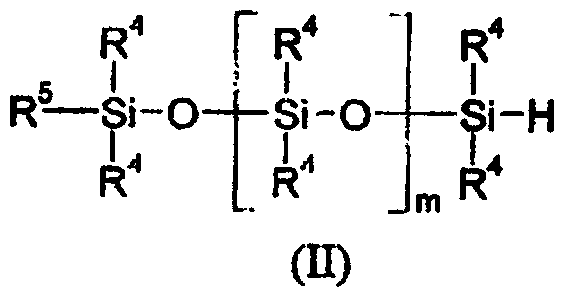

[0162] Thoroughly mix 300 parts by weight of polydivinyldimethylsiloxane (component A) with a viscosity of 50 mPa·s, 30 parts by weight of polydimethylsiloxane (component A) with a Si-H content of 7 mmol / g Component B), 5 parts by weight of 3,5-dimethyl-1-hexyn-3-ol (component D), 0.5 parts by weight of 1% Karstedt's 1,2-divinyltetramethyldi A silicone solution (component C), and a base mixture of 170 parts by weight of a linear polydimethylsiloxane having terminal vinyl groups and terminal Si-H units (component F). At 25°C, the viscosity of the mixture was 40 mPa·s.

[0163] Then, 0.1 parts by weight of diepoxy polysiloxane (component G) with a viscosity of 10 mPa·s and 3 parts by weight of fumed silica coated with dimethylsilane were added to 96 parts by weight of the mixture (Component E).

[0164] At 25°C, in 0.01s -1 The viscosity measured at the shear rate is 430000mPa·s, at 500s -1 The viscosity measured at the shear rate is 120mPa·s.

[0165] Coated according to t...

Embodiment 2

[0167] To 98 parts by weight of the base mixture from Example 1 were added 0.1 parts by weight of diepoxypolysiloxane (component G) with a viscosity of 10 mPa·s and fumed dioxide partially coated with dimethylsilane. Silicon (component E).

[0168] At 25°C, in 0.01s -1 The viscosity measured at the shear rate is 8000mPa·s, at 11s -1 The viscosity measured at the shear rate is 120mPa·s.

[0169] Coated according to the method described above, a uniform coating curtain was obtained, and after coating, the coating on the printed circuit board did not flow anymore.

Embodiment 3

[0171] To 97 parts by weight of the base mixture from Example 1 were added 1 part by weight of diepoxypolysiloxane (component G) with a viscosity of 10 mPa·s and 2 parts by weight of uncoated fumed silica ( Component E).

[0172] At 25°C, in 0.01s -1 The viscosity measured at the shear rate is 390000mPa·s, at 400s -1 The viscosity measured at the shear rate is 120mPa·s.

[0173] Coated according to the method described above, a uniform coating curtain was obtained, and after coating, the coating on the printed circuit board did not flow anymore.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com